Air compressors and pneumatic tools make it possible to achieve in seconds what might take hours to accomplish by hand. When it comes to cutting hard materials and loosening long-tightened bolts, an air-powered tool can instantly perform what would otherwise be impossible. However, it’s important to know the air pressure requirements of a given tool or application.

Contact Us Learn More Find a Dealer Near You

Air Pressure by Application

So how do you know how much air pressure is needed for a given application? Air tools made for general use with portable air compressors typically require 0 to 5 cubic feet per minute (cfm) at 70 to 90 pounds per square inch (psi), whereas with larger tools connected to stationary systems, the requirements usually exceed 10 cfm at 100 to 120 psi.

When used intermittently, standard-sized tools for certain applications have specific air pressure requirements. However, it’s important to remember the varying cfm levels should be multiplied by four when continuous usage comes into play.

Here are some of those applications, as well as their corresponding cfm levels:

Angle grinding.

In car maintenance and repairs or in metalwork, an angle grinder is used for cutting, grinding and buffing. An angle grinder can even be used for sanding surfaces and edges on certain materials, providing the tool is equipped with the right disc. Angle grinders can also be operated with one hand or two — a side handle is featured on most models to allow for the two-handed option. For general applications, a standard 7″ handheld angle grinder requires 5 to 8 cfm at 90 psi.

Brad nailing.

In construction and home renovation, this tool is used to drive deep — embedding brad nails into wall and door trimmings, as well as other parts of a house or building where regular nails would be deemed visually intrusive. The namesake nails of this tool are thin, headless nails that are far less assuming to the naked eye than regular, flat-headed nails. As a relatively lightweight pneumatic tool, a brad nailer generally requires only 0.3 cfm at 90 psi.

Chiseling.

As a tool that’s sometimes used to cut through metal, an air chisel is one of the heavier-duty handheld pneumatic tools. With its flat, narrow cutting edge, an air chisel can also be used on stone or wood, which makes it a useful tool in the construction and renovation of homes and buildings. Chisels are especially handy for cutting out dovetail joints and mortises when constructing adjoining walls and shelf panels. In general uses, an air chisel requires 3 to 11 cfm at 90 psi.

Cutting.

If there’s one tool that requires power, it’s the cut-off tool, which is made to cut through sheets of metal for crafts work, home or auto maintenance and industrial applications. Whether you need to cut corners off of metal sheets or panels out of metal walls, an air-powered cut-off tool will perform the task in seconds. In a sense, metal appears like paper against the spinning discs on these tools, which require 4 to 10 cfm at 90 psi.

Drilling.

With hard materials, air compressors are especially helpful for drilling, which is widely considered a difficult task among the shaky handed. Thanks to the power and speed of pneumatic drills, the drill bits go in and come out so fast that there’s little time for the clumsy arm and hand moves that could otherwise send things in diagonally instead of straight. Whereas traditional electric-powered drills can only penetrate wood, pneumatic drills have the power to also drill into metal and rock. Whether straight-line or reversible, an air-powered drill requires 3 to 6 cfm at 90 psi.

Dual sanding.

Before the invention of power tools, few tasks were as exhausting to the palm, wrist and elbow as sanding. While most of the heavy lifting and pressure was concentrated in the sawing, cutting and nailing stages, more actual hand motion was needed just to get each raw-cut surface refined to a nice, smooth finish.

Thankfully, the intensive labor involved in sanding has since been liberated by air-powered dual sanders, which sand and buff in seconds flat. This can all be achieved by simply holding the tool above the surface. Great for metal and woodwork, dual sanders require 11 to 13 cfm at 90 psi.

Frame nailing.

When framing the interior of a house, you can go through dozens of nails within a few short minutes. With a framing nailer, you don’t have to keep nails on hand because nail belts load into the tool like bullet rounds into a machine gun. An air-powered framing nailer allows you to fasten boards together by the dozen in only a fraction of the time it would take with a hammer, whether you’re working on the wall frames or rafters. Most amazingly of all, a framing nailer only requires 2.2 cfm at 90 psi.

Greasing.

The moving parts of machinery rely on lubrication, which is the only thing that protects rubbing metal surfaces from friction wear and consequent heat. In vehicles, for instance, grease guns are used to lubricate door hinges and engine parts. Applying grease manually could be a messy operation, but an air-powered grease gun makes the whole job neat and tidy. A grease gun is also a simple and relatively low-pressure pneumatic tool to operate, as it only requires 4 cfm at 90 psi.

Metal nibbling.

People often stare in wonder at furniture, fixtures and artwork comprised of carved and uniquely cut sheet metal. If you see a metal wall-hanging in the form of a silhouetted sun, moon, flower or animal, chances are it was done by hand with an air metal nibbler. In a similar manner to how X-Acto knives and ion cutters carve shapes out of paper and cardboard, nibblers make cutting metal as easy as cutting paper.

Additionally, nibblers are good for trimming inches off metal surfaces and contouring the corners of otherwise sharp metal ends. When properly guided along sheet metal with minimum arm pressure, an air nibbler requires 4 cfm at 90 psi.

Mini grinding.

Even the smallest of metal and wood objects are sometimes in need of maintenance. Whether you’d like to grind and smooth out the edges on certain trays or polish and buffer the surface of an old coin, the mini die grinder is an ideal pneumatic tool. A mini die grinder can also be used for moderate-relief wood stenciling and other crafts work. From sanding tips to buffer wheels, the tool is lightweight regardless of the attachment. A mini die grinder requires 4 to 6 cfm at 90 psi.

Needle scaling.

Even though metals are the strongest material type, they’re still prone to rust, scale and other residues that stem from exposure. Comprised of numerous rattling steel needles, air needle scalers have the power to remove weld slag, rust, paint and various other signs of wear from hard surfaces. If you see welds on a metal bracket, it can all be removed by gently running an air needle scaler back and forth a few times over the surface area. The needle scaler allows you to restore metal surfaces to shiny smoothness in seconds, and it only requires 8 to 16 cfm at 90 psi.

Orbital sanding.

It’s hard to imagine sufficiently smooth wood surfaces without the invention of the orbital air sander. Designed to make the often exhausting task of sanding as easy as waving your hand across a surface, an orbital sander takes the roughness out of wood panels before they’re finally sold as shelves, tables and bookcases.

Ideal for artisans and industrial woodworkers alike, the round-disc head of the sander moves in ellipses across each surface, which ensures smoothness by never running over the same spots in the same way twice. With only modest amounts of hand pressure, a pneumatic orbital sander requires 6 to 9 cfm at 90 psi.

Painting.

Perhaps the greatest of all pneumatic tools is the air paint brush, which eliminates the streaks, splotches and inconsistencies that are often hard to prevent when painting by hand. As one of the most delicate steps in the final stages of vehicle, building and furniture completion, the flow of paint needs to be free of dirt and moisture. These requirements are made possible with a pneumatic airbrush, which allows you to apply layers of paint and glaze at a perfect standard that could never be matched by rollers, brushes or aerosol spray cans. For some of the finest colors and finishes, an airbrush requires 3 to 11.3 cfm at 90 psi.

Ratcheting.

The tightened bolt can be a stubborn beast, especially when it’s been in place since the day the parts in question were fresh off the assembly line. With its short handle and sideways jack, the socket wrench (or ratchet) allows you to dislodge bolts in tight, narrow places that would be hard to reach with a larger, perpendicular tool.

If you’re having problems with your vehicle, for example, an air ratchet makes it easy to remove and replace the problem pieces under the hood without having to take the vehicle in for service. For all the money that home mechanics save with this handy tool, the per-size requirements of a 90 psi impact wrench are as follows:

- 1/4″ = 2.5 to 3.5 cfm

- 3/8″ = 4.5 to 5 cfm

Riveting.

Some people assume that the rivet went the way of the dodo once welding came along, yet the permanent fastener is still used in plenty of industrial applications. For instance, rivets are preferred in constructions where fastening must be as strong as possible, but where weight must be kept to a minimum, such as with airplanes. A hydraulic riveter can also be used in home construction, such as when attaching corrugated metal roofing. As one of the less consuming pneumatic tools, the hydraulic riveter requires 4 cfm at 90 psi.

Sawing.

On some metal projects, all that’s needed is a clean, simple slice or corner cut, without the metal confetti strips that fall to the wayside during air-shear applications. Contemporary pneumatic saws average 9,000 strokes per minute, which allows for speed and precision when cutting through layers of 16-gauge sheet metal, as well as through plates and strips of aluminum, copper and plastic. From garden ornaments to pipe art, an air-powered speed saw can serve as a vital tool in the construction of various forms of copper and metal crafts, not to mention automotive and industrial applications. In order to run at optimal capacity, an air speed saw requires 5 cfm at 90 psi.

Shearing.

When it comes to heavier-duty metal cutting, you need more than a mere nibbler. With an air shear, you can slice, trim and outline sheet metals for industrial and craft projects. Armed with pistol-grip shears, today’s versions of the pneumatic tool can make roughly 2,600 cuts per minute. Whether you’re working on metal furniture or fixtures, the standard air shear can cut through cold-rolled steels as thick as 20 gauge, as well as 16-gauge sheet metal and 14-gauge aluminum. An ideal tool for metal workshops of all capacities, an air shear requires 8 to 16 cfm at 90 psi.

Unscrewing.

When a screw or bolt seems welded into place, the truth is somewhere in the middle. While time and the elements can make a tight bolt impossible for even the strongest person to unscrew manually, an impact wrench will perform the job in a matter of seconds. If there’s a hitch on the back of your truck for a boat or trailer that you no longer use, that hitch could easily be unbolted — regardless of how much rain and harsh temperatures it has endured — with a 1.5″ impact wrench.

An impact wrench can also be used for applying or removing hubcaps as well as for putting together and taking apart fences, decks and outdoor structures. Best of all, an impact wrench requires virtually no strength or strain on the user’s part, regardless of whether it’s used for reverse or forward applications. Per nozzle size, the requirements of a 90 psi impact wrench are as follows:

- 3/8″ = 2.5 to 3.5 cfm

- 1/2″ = 4 to 5 cfm

- 1″ = 10 cfm

How to Calculate Compressor CFM

Your pneumatic tools and air compressor are rated for cfm. This rating indicates the volume of air required by the air tool or produced by the compressor at a given pressure level. Knowing how much psi you need for an air compressor application will help determine how much cfm the compressor requires to operate your air tools effectively.

Your tools’ cfm requirements can provide an idea of the cfm needed from your air compressor, but you will also need to consider the pressure levels required for the specific function this tool will be performing. Simply matching your air tool’s rating to the compressor’s rating will not always be enough. That’s where this guide and our handy air compressor cfm chart come in.

How much cfm your air compressor needs is determined by a few factors — the type and number of tools you need to power and whether your tools are required for continuous or intermittent use.

The Type of Tools

Consider the cfm requirements of your specific air tool or tools. The manufacturer’s guidelines should specify this information in the tool manual. If you’re using a single air tool, be it a 1/2″ drill or a 90-pound jackhammer, your air compressor’s minimum cfm rating should be the highest cfm marked for that tool.

It’s crucial to account for the duty cycle when determining your air compressor’s cfm requirements. In this case, the duty cycle refers to the percentage of time an air compressor can run before needing a break to catch up or cool down. The average cfm rating for air tools is usually based on a 25% duty cycle. Because of this, it is often recommended that your compressor’s cfm rating is 1.5 times that of your air tool. This adjustment will prevent your air compressor from overworking.

If your team must use tools for extended periods, consider your compressor’s cfm requirements on a 100% duty cycle. Additional calculations may be necessary, so it is vital to assess what tools you use and how you use them.

The Number of Tools

Using multiple tools at once will impact your compressor’s cfm requirements. This situation is common in factories and workshops where two or more people work a single job or jobs in close succession. The ability to run multiple tools can significantly boost your team’s effectiveness, so it is essential to plan for this possibility.

If you’re running multiple tools from the same air compressor, you’ll need to add the individual cfm ratings of each tool to determine your compressor’s total cfm requirement. For example, a team that simultaneously uses a 2″ grinder that requires 30 cfm and a 1″ impact wrench that requires 60 cfm will have a total demand of 90 cfm. This means the workers must have an air compressor that reliably produces 90 cfm of air to power both devices.

In this example, the air tools’ cfm ratings are already calculated at a 100% duty cycle. It is important to consider whether your tools will be used continuously or intermittently, especially when using multiple devices at once. If you are aiming for continuous operation of more than one tool, you may need to multiply the total cfm by 4 if the individual tools are only rated on a 25% duty cycle. Using multiple tools continuously can require a significant volume of air.

Continuous vs. Intermittent Use

How you use your tools is vital. When determining your air compressor’s cfm needs, it is important to examine how you and your team operate daily. Do you work in quick bursts with short breaks, or must you use your tools for lengthy periods? Does the air compressor have adequate time in between use periods to catch up and cool down?

Asking yourself these or similar questions will ensure you operate your tools with their intended use in mind. If your application requires you to run air tools for an extended period, you must calculate your air compressor’s cfm requirements on a 100% duty cycle. In contrast, general air tools used for intermittent bursts may get by with a less powerful but more cost-effective compressor.

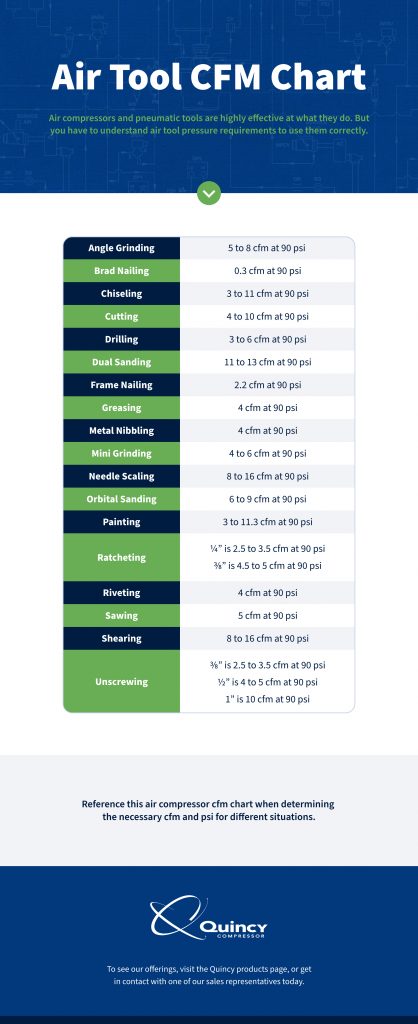

Air Compressor CFM Chart

See how much cfm you would need to operate some of the most common tools at peak performance. This air compressor cfm chart outlines the air pressure required for particular applications.

The Right Air Pressure for Each Application

From grinding, chiseling and drilling to sanding, painting and greasing, it’s crucial to have an air compressor that can provide the right amount of air pressure for each application. Whether you run an auto repair shop or a metal-working studio, or you simply do metal or woodwork in your home garage, Quincy Compressor supplies numerous machines that cover the needed specifications for a vast range of pneumatic tools.

Since 1920, Quincy has been at the forefront of all the latest innovations in air compressor technology. Throughout the United States and abroad, our machines and tools have been used at factories, assembly plants, repair shops and in private workshops. For operations large and small, Quincy air compressors have allowed mechanics, technicians and artisans to get optimal results with just the right pressure for each application.

Quincy compressors have saved money and time while relieving strain and providing optimal results for companies, work teams and private users, and our products can do the same for you. If your equipment arsenal has given you lackluster results and you need a system that provides moisture-free compressed air for various tools, check out the Quincy products page to learn more about our offerings. Then, contact our sales representatives who can assist you in getting the air compressor that will allow you to complete your necessary tasks with ease.

Last Updated on October 26, 2021 at 3:10 pm

Contact Us Learn More Find a Dealer Near You