Air leaks are expensive but can be identified and repaired

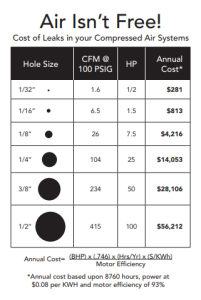

All compressed air systems have leaks. These have several causes, including corrosion holes, poor pipe connections and bad seals. Compressed air systems on average lose 20% to 30% of compressed air due to leaks. This is a huge waste of money.

How much money are you hissing away?

A typical 200HP installation wastes $46,531 due to air leaks. This could be avoided with a leak study and your power bill is the proof! Quincy is here to help.

How Quincy’s Leak Detection solution compares to others

We use an acoustic imaging camera which can help detect leaks in compressed air systems much faster than traditional methods. Conventional leak detectors use one (1) microphone while our camera takes measurements with 124 microphones which enables you to pinpoint the leak locations and assign priority based on the size and cost estimation.

What makes our solution industry leading?

- Locate smaller leaks due to the increased sensitivity of the camera. Detects leaks up to 426 feet away from the technician.

- Perform leak studies much faster due to the increased detection range (average detection of 2 leaks every 5 minutes)

- Real time analytics for leak size and leak cost estimation

- Minimal training on how to use the leak camera.

- Much safer due to no soundproof headset requirement

- Automatic report creation

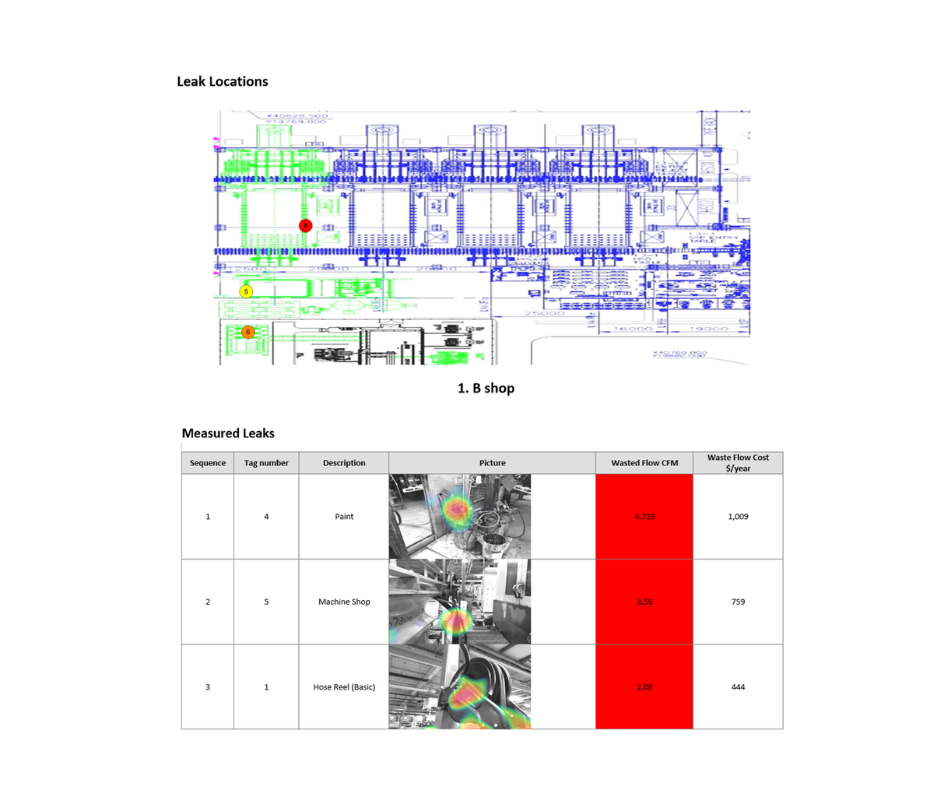

An audit provides a high value report after the leak study is completed

Once the leak audit is completed it is simple to generate a professional customer facing report. The report summarizes the findings and makes it clear as to what actions will provide the customer with the best results.

- Location of each leak is visible on your facilities site map

- Ranks leaks by the annual loss of CFM and Dollars

How much air are you hissing away?

Contact your Quincy representative today to schedule a leak audit.