When it comes to an air compressor, maintenance in the standard form is never enough. To ensure the smooth running of operations and avoid interruptions and unexpected downtime, it is crucial to have a compressor maintenance program in place that prevents — rather than reacts to — problems with the air compressor and all attached tools and machinery.

Learn more about how to maintain an air compressor to keep it in its best condition.

The Difference Between Preventive and Standard Air Compressor Maintenance

In smaller businesses, maintenance is a standard procedure that amounts to toner refills and software and hardware upgrades. Essentially, standard maintenance is what you perform on equipment that works consistently until it expires or becomes outmoded by newer technology.

At facilities that employ high-tech machinery, you must perform more than just standard maintenance to ensure the operability and longevity of all the expensive equipment on hand. Air compressors need a preventive maintenance program that inspects the machine and its system peripherals regularly. These scheduled checks ensure everything is in fully functioning condition.

The purpose of preventive maintenance is to catch mechanical problems before they spread and necessitate costly repairs and system downtime. Preventive maintenance involves inspections of all system components — some according to a daily schedule, others on a weekly, monthly, quarterly or annual basis — to ensure everything works properly. If you detect problems early, you can take steps to rectify matters before they grow worse.

In some cases, preventive maintenance involves low-cost measures that help avoid costlier situations down the line. For example, when a maintenance staffer notices a compressor belt has a minor crack, replacing the belt right away helps your company prevent a costlier scenario. Otherwise, the belt could snap, causing the compressor to stop working and production to stop. The staff might be unable to identify the problem for a significant amount of time, leading to excessive downtime.

The Benefits and Value of Preventive Maintenance for Industrial Air Compressor Systems

Regardless of the size or scope of your compressor operation, you need a dedicated staff member to oversee daily preventive maintenance work. A consistent maintenance schedule ensures machines work each day until reaching their complete life span. More benefits of preventive maintenance include:

1. Avoiding Downtime

One of the most significant benefits of compressor maintenance is the decreased downtime. When machines function incorrectly, production usually halts, resulting in lost revenue. Preventive maintenance keeps machines running smoothly and efficiently, minimizing slowed production times.

Without maintenance, you might face frequent performance issues. These could arise at inconvenient times, like during a major production request with a looming deadline. You should perform maintenance every day to avoid these problems, even when nothing appears to be wrong.

2. Saving Money by Avoiding Costly Emergency Repairs

With reduced occurrences of downtime and parts failure in your air compressor system, you save money. As such, you profit both ways — through increased productivity and reduced overhead. The money you save through timely compressor maintenance allows you to invest more in better equipment as innovations reach the market.

Without maintenance, the costs involved in the repair of an air compressor and its peripheral parts can take a huge chunk from a company’s annual earnings. When you conduct timely maintenance, you’ll reap savings you can pass on to your company through higher wages and less expensive products.

3. Lowering Energy Costs

When you perform air compressor maintenance on a regular schedule, it allows you to catch instances where a function within the system is over-exerting or struggling to maintain an expected rate of production. When such issues do arise, it is often down to a part that needs cleaning, replacement or lubrication. By spotting these problems before they grow out of hand, the machine runs smoother and more efficiently, which translates to energy savings.

Of course, energy savings also amount to money saved in your overall production costs. With lower monthly energy costs, you can invest the money back into the infrastructure of your company.

4. Increasing Air Compressor Life and Efficiency

Of course, the greatest benefit of air compressor maintenance is that it increases the life and efficiency of the machine itself and the system as a whole. When you add up the initial cost of investment in an air compressor and all the attached pneumatic tools, you want to ensure a return on that investment through years of optimal performance. Ideally, the money you spend on your compressor system should reward you thousands and thousands of times over through productivity.

Without maintenance, an air compressor and its peripheral components will not last as long as it otherwise could with regular checkups, tune-ups and cleanups. When you compare the profits of companies that implement responsible system maintenance with those that do not, you are liable to see major differences in productivity.

Recommended Preventive Maintenance Checks for Your Compressor

On an industrial air compressor, preventive maintenance is crucial to ensure the functionality of the system and its various attachments. Key parts include the filters, vents, belts and bearings, all of which could become troublesome to the system if dirt and grime accumulate. Moreover, you must apply and reapply lubricant at timely intervals on all applicable parts of an air compressor.

The following components are the most important to inspect, clean and lubricate according to schedule:

1. Air Filter

The purpose of an air compressor is to produce clean, pure, compressed air that will ultimately power numerous functions. To ensure the quality of air that comes out at the end, the ambient air that goes into the compressor must be filtered of impurities before it leaves the machines. None of that could be possible without a clean air filter.

If the air filter is dirty, impurities and particulates could corrupt the compressed air and degrade the quality of end-point applications. Therefore, clean the air filter regularly. Change it out at regular intervals, which vary based on the environment.

2. Oil Filter

Oil can degrade the quality of compressed air if it passes through the system and gets carried to the end of an application. Some of the worst-affected processes would include pneumatic spray painters, air cleaners and anything else where oil could corrupt the surface in question. Therefore, it is crucial to ensure oil, when present in the system, is removed from the compressed air before the air leaves the machine.

Check oil filters weekly, regardless of whether the compressor is lubricated or non-lubricated. Moreover, replace the oil filter entirely at recommended intervals, which can range from 4,000 to 8,000 hours of use depending on your unit. If the oil filter gets heavily covered in oily residue before that time, replace it sooner.

3. Lubricant

Lubricant is one of the most vital elements in the function of an air compressor. On all the internal metal parts and joints, lubricant allows for smooth, non-corrosive movement. Without lubrication, tension occurs between the touching metal surfaces, which leads to the corrosion of parts and joints. Once corrosion takes hold, rust is liable to spread and eat through certain mechanical parts.

However, even when lubricant is present, it can lose its viscosity and become corrosive if it gets too old. Check the lubricant level daily to ensure the health of your air compressor. Every three to six months, wipe off old lubricant and reapply a fresh coat. Each time you replace the lubricant, be sure you also change out the separator element.

4. Motor Bearings

For a motor to run, the bearings must have proper lubrication. The tiny metal balls are constantly rolling against each other, as well as against the interior walls of the round encasement. Consequently, rust could form on the bearings without proper lubrication. If rust forms, the bearings will gradually slow and ultimately become stuck in place. When this happens, the motor fails.

To protect the health and performance of the air compressor motor, grease the bearings every 4,000 hours. Be sure to inspect the bearings at quarterly intervals between each greasing to ensure they remain sufficiently lubricated.

5. Belts

For an air compressor to go about its internal motions, the belts must have proper tension. The rubber of each belt must also remain firm, yet flexible, to ensure balanced movement between the pulleys of connected parts. Over time, however, the rubber on a belt will inevitably wear down and crack in certain places. Therefore, it is crucial to replace the belts before they lose their tension or, even worse, snap in the middle of an operation.

Inspect each belt once per week to verify they are free of wear. Adjust the tension if necessary and replace each belt once wear takes hold.

6. Intake Vents

An air compressor performs the magic feat of transforming ambient air into something that can power heavy-duty machinery and effectively serve as a replacement for electrical power. That said, the compressor itself can only do so much to turn mundane air into something powerful. While internal components do their job to purify the air for end-point use, that job is harder for the machine to perform if the intake vents become lined with dirt and grime.

To ensure the incoming air remains as clean as possible and to prevent dirt from getting sucked into the system, inspect the intake vents weekly and clean them when necessary.

7. Other Parts to Check

In addition to the periodic cleaning, lubrication and replacement of parts, check various points along the air compressor and its attachments at regular intervals. Inspect the following every week:

- Air dryer performance

- Amps

- Oil level

- Temperatures

- Vibration

- Voltage

Inspect the air compressor for signs of oil or air leaks. Also, check the pneumatic hoses for air leaks, as leakage severely reduces the efficiency of an air compressor. Furthermore, make sure the coolers are free of dirt.

How to Service an Air Compressor With a Preventive Maintenance Checklist

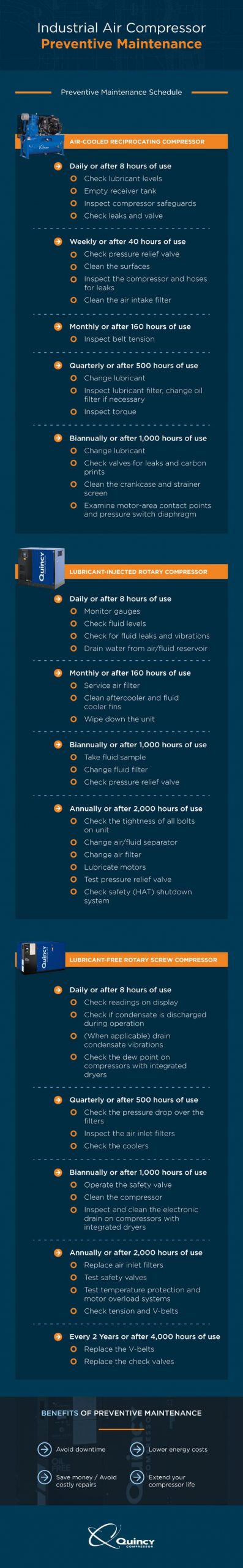

When you make an air compressor preventive maintenance checklist, you need to first take into account the type of compressor in question. Most compressors need preventive maintenance on various system parts at intervals that range from daily to annually. Here is a closer look at various compressor types and their maintenance requirements:

1. Air-Cooled Reciprocating Compressor

To service an air-cooled reciprocating compressor, perform the following steps every day, or after every eight hours of use:

- Check the lubricant level to verify it never drops below the mid-range of the bayonet gauge. If the lubricant becomes discolored, empty and refill it.

- Empty water out of the receiver tank.

- Visually inspect the compressor and verify the safeguards are in place.

- Check for leaks and vibrations.

Every week, or after every 40 hours of use, complete these maintenance tasks:

- Check the pressure relief valves.

- Clean the surfaces of the compressor and intercooler.

- Inspect the compressor and hoses for air leaks.

- Clean out the air intake filter.

If you face humid or dusty weather, perform these steps twice each week, or after every 20 hours.

Follow these steps for periodic maintenance:

- Monthly: After a month or 160 hours of use, inspect the belt tension inside the air compressor.

- Quarterly: Every three months, or after every 500 hours of use, you should change the lubricant and inspect the filter. If needed, change the oil filter. You should also inspect the torque on the pulley nuts and screws.

- Biannually: Every six months, or after every 1,000 hours of use, you should change the compressor’s lubricant. You should also check valves for indications of leaks or carbon prints. In addition, clean the crankcase and its strainer screen. Examine the motor-area contact points and pressure switch diaphragm.

2. Lubricant-Injected Rotary Compressor

Follow these maintenance recommendations for your lubricant-injected rotary compressor. Each day, or after every eight hours of use, complete the following tasks:

- Monitor all gauges and indicators for normal operation.

- Check fluid level.

- Observe for fluid leaks.

- Observe for unusual noise or vibration.

- Drain water from the air and fluid reservoirs.

Every four weeks, perform the following tasks:

- Service air filter as needed. This should be a daily or weekly task if extremely dirty conditions exist.

- Clean aftercooler and fluid cooler fins, for air-cooled units only.

- Wipe the entire unit down to maintain appearance.

Every six months, or after every 1,000 hours of use, complete these maintenance needs:

- Take fluid samples.

- Change fluid filters.

- Check the pressure relief valve.

After a year of use, follow these guidelines:

- Go over the unit and check all bolts for tightness.

- Change the air and fluid separator.

- Change the air filter.

- Lubricate the motors.

- Test the pressure relief valve for proper operation.

- Check the safety (HAT) shutdown system.

3. Lubricant-Free Rotary Screw Compressor

You can service your lubricant-free rotary screw compressor with these guidelines.

For daily maintenance, or after every eight hours of use, perform the following tasks:

- Check displayed readings.

- Check if condensate is discharged during operation.

- Drain condensate manually (when applicable).

- On compressors with integrated dryers, check the dew point.

Every three months, or after 500 hours of running use, perform the following tasks:

- Check the pressure drop over the (optional) filters.

- Inspect the air inlet filters: check for cleanness and damage. Replace a dirty or damaged filter with a new one.

- Check the coolers. Clean by air jet if necessary.

After every six months or every 1,000 hours of use, complete these maintenance jobs:

- Operate the safety valve.

- Clean the compressor.

- On compressors with an integrated dryer, brush or blow off the finned surface of the condenser. Inspect and clean the electronic drain.

Perform these tasks every year:

- Replace the air inlet filters.

- Test the safety valves.

- Have temperature protection and motor overload tested.

- Check the tension and condition of the V-belts.

After two years of use, replace the V-belts and check valves.

Which Maintenance Checks Should a Technician Perform?

Company staff at a given facility or plant can generally perform air compressor preventive maintenance in-house. However, it’s better to let professional compressor service people perform some maintenance tasks — even more so if the unit is large or complicated. Unless your company is staffed with highly skilled personnel to handle maintenance tasks with air compressors, it is best to contact a professional for the following:

- System safety-shutdown inspections

- Motor replacement

- Relocation of large, heavy air compressors

- When you don’t have qualified staff to work on your compressed air systems.

- When mechanical breakdowns occur.

When you hire a professional for these and other time-consuming and possibly dangerous tasks, it can help you save time and money and also ensure that the job is done properly. Moreover, professional maintenance ensures utmost safety for the more difficult aspects of the job.

Do You Make These Common Mistakes in Air Compressor Maintenance?

Even with a robust preventive maintenance plan, operators can make mistakes. If you only have a basic understanding of compressor operation, you might be more likely to encounter maintenance problems. These mishaps can cause inefficiencies and lost revenue. By learning about common air compressor mistakes, you can prevent yourself from committing them.

Our nine common air compressor mistakes include:

1. Being Unaware of Compressed Air Energy Costs

One of the biggest compressed air maintenance mistakes is underestimating or miscalculating the amount of energy a compressor uses in a year. The price to operate an air compressor can equal or exceed the purchasing cost of the machine in just 12 months. Wasteful usage of a compressed air system leads to high overall energy costs.

On average, an industrial air compressor costs between $30,000 and $50,000. When you multiply the operating costs per hour by the number of usage hours per day across 12 months, the cost of operating the machine during the first year alone could exceed the initial price. This calculation doesn’t even involve possible maintenance expenses.

A reliable way to estimate annual energy costs is with this formula:

- Take the compressor’s horsepower and multiply that by .746.

- Multiply the result by the number of usage hours.

- Multiply that result by the power rate.

- Divide the total by the motor efficiency.

You can avoid surprise costs by calculating the estimated expenses in advance. Make sure all staff understand this value and how to abide by it.

2. Limiting Inspections to the Air Compressor

Comprehensive air system inspections are necessary for successful maintenance. If you only glance at the system to check for dirt or condensation, you won’t catch more significant problems. People often skip steps when their compressor appears to function perfectly. However, more significant problems might exist below the surface.

Even though the compressor is the main component of concern within an air system, it’s not the only one that needs routine maintenance. Other parts that facilitate air supply also require inspections and upkeep, such as the air receiver. This component holds compressed air when demands increase and reduces system wear and contamination.

The air receiver allows you to run the compressor at lower levels, conserving energy in the process. However, the air receiver cannot complete its job properly if it’s too small for the system, as the compressor might have to run longer than necessary to keep up with air demand. Therefore, it’s important to ensure the air receiver is either large enough for the system or backed with secondary receivers.

3. Ignoring Air Leaks

Air leaks can waste up to half the air produced within a compressed air system. When it comes to the operation of an air compressor, some of the greatest savings can be made with regular air–leak maintenance.

To understand the cost of an air leak, imagine the waste of just one small leak within a system. For instance, in a 100 psi system, a leak of merely 1/4 inch will pass around 100 cfm. On a system that runs 24/7 at $0.07 kW, the leak could waste approximately $12,000 of compressed air per year. Surprising as it sounds, an air leak small enough to evade the naked eye can in fact result in losses that will extend into the tens of thousands.

Granted, the process of air leak maintenance does not just end with the pipes. It’s also necessary to monitor all components along a system to ensure that no air is leaked throughout the process. Other parts that should regularly be checked include the valves, connections and fittings. However, air–leak maintenance can only be truly effective at stemming excess costs if the compressor controls and air delivery parts are also functioning correctly.

4. Ignoring Pressure Loss in the Piping System

One major problem that emerges in compressed air systems is pressure drop, which is marked by a loss of pressure between the compressor and the end point. While a certain amount of pressure drop is inevitable, it should never amount to more than a 10 percent loss of pressure during a given application. Otherwise, higher pressure demands end up being placed on the compressor, which results in more rapid wear and tear across the entirety of an air system.

For each pound of pressure either increased or decreased, a power plus or minus 0.5 percent is required. For example, a five percent power savings can be gained with a decrease of 10 psig. On a 100 hp compressor, this would translate to $1,740 in annual energy savings.

Pressure drop is usually caused by trouble with the pipes and weaknesses at the filters and dryers. Unfortunately, system operators will often compensate for the pressure loss by boosting the system pressure, which results in costlier operations. The correct way to handle this issue is to check for problems at the filters and dryers and replace certain items as necessary.

5. Failing to Remove Pipe Contamination

It’s crucial for air system pipes to remain clean and free of dirt, rust or other contaminants. After all, compressed air reaches its end point through these pipes. When contaminants are present, air pressure weakens, and the problem gradually accelerates when left un–rectified. The pipes should always remove air from the top of the air line, otherwise contaminants will travel to the pneumatic tools.

Airstream contamination increases with velocity, which in turn increases with restrictions in pipe size. Basically, the velocity of the pipes that run to the end point should be 50 seconds or less, while the interconnecting pipes and main headers should have velocity in the range of 20 to 30 feet per second. System velocity can be calculated by dividing the flow in cfm by the pipe’s compression ratio, divided by the pipe area, divided by 60.

6. Failing to Manage Condensation

Poor condensation management can lead to numerous problems with a compressed air system. Condensation emerges during the cooling process as moisture is sucked from the air. As the droplets build up within the interior of an air compressor, the following problems are liable to emerge:

- loss of lubrication in the pneumatic tools as condensate washes oil away

- inconsistent quality of air at the end point

- air distributes with excess amounts of rust or scale

- water accumulates within the machine and ruins the circuitry

Additionally, condensation can overload in the air dryers and ruin the in–line filters. The problems with condensation are often especially pronounced in rotary screw air compressors, where the compressor oil will sometimes spread into the air system when mixed with the condensate. The combination of oil and water can lead to dirt deposits that ultimately clog the drains and pneumatic tools.

Another factor that can impact condensation is the ambient temperature that surrounds a facility. Simply put, condensation levels multiply as temperatures rise from average to humid. For example, a 200 hp compressor will produce roughly 50 gallons of condensate over the course of a 60–degree day. However, that same machine will generate more than five times the amount of condensate if the temperature is 30 degrees higher.

Further inefficiency can stem from problems with the system drains, which are designed to deal with condensation. Drains are placed at strategic points along an air compressor system, such as the tank, dryer and aftercooler. The trouble emerges when the drain fails to do its job properly, and sludge accumulates along the drainage points from a mix of water, oil and dirt.

System operators will often expect the drains to handle such issues automatically, but this is a big mistake. Condensation can lead to a huge waste of system resources if the issues that lead to condensation are not monitored and rectified on a regular basis.

7. Failing to Review Air Demand for Individual Departments

In a spread out industrial plant, the compressed air needs for one department could differ from the others. While the pressure requirements could be at one uniform level across most of the facility, higher pressure may in fact be needed for that one department. Pressure inevitably gets wasted, however, when the entire air system is ran at a higher pressure just to suit the needs of the one department in question.

At multi–department plants that operate a large number of air compressors, it’s crucial to evaluate the needs of each department to determine if one or more has higher needs than the rest. For the departments that do, smaller compressors should be installed in those areas to meet the exclusive needs of said department. That way, the rest of the plant can operate at uniform pressure without wasting air pressure.

8. Failing to Train Air System Staff

At certain facilities, machine operators are less knowledgeable than management personnel of the overall intricacies of an air system. This is problematic when you consider how costs can accumulate annually with just slight amounts of daily inefficiency. Therefore, it’s not sufficient when floor staff are only trained on the basic protocols of machine operation, yet lack a broader understanding of how air compressors work.

The operation and management of an air system necessitates an in–depth knowledge that goes way beyond a simple handiness with the machines. In order for air compressors to be operated efficiently, it’s important for everyone on a team to understand the costs of operation. To that end, all staff should be informed on energy conservation and the relationship between the various components within an air system.

9. Not Compiling Troubleshooting Data

When you know the behavior of a fully functional air system, it’s easier to spot the emergence of problem issues before they spiral out of hand. Some of the worst problems with an air conditioner will start slowly and gradually lead to more costly issues down the line, yet time and money can be saved when such issues are identified sooner. Trouble is, the management at certain facilities fail to record and evaluate data on system operations. Without that knowledge, it’s hard to spot inconsistencies in system patterns.

The secret here is to collect data on system performance on a regular basis to determine the range of behaviors that characterize a fully functional air system within a given setting. Readings should be taken at various points along the system, including the compressors, aftercoolers, receivers, filters and pneumatic tools. Once the accepted patterns have been established, deviations in performance can serve as red flags of potential system issues. Most importantly, information should be gathered of how a compressor normally operates at full load.

The foremost sign of trouble is when temperatures increase beyond the established level within an air system. When temperatures are monitored over time, a baseline can be established that makes it easier to spot deviations. An easy way to read such data is with the use of an infrared thermometer, which gathers data piece by piece when directed at each component along an air system. While this only reads surface temperatures, it can still provide useful data for future troubleshooting.

Make a Compressor Preventive Maintenance Plan

To ensure maximum efficiency and an absolute minimum of downtime and repair costs with your air compressor, complete preventive maintenance checklist tasks according to a set schedule. Depending on the needs of a given component, perform maintenance daily, weekly, monthly, quarterly or annually.

When you perform preventive maintenance according to a checklist, your air compressor and its attachments will last longer and perform with greater efficiency. Preventive maintenance makes it possible to detect problems at an early stage before they do serious system damage and lead to costly repairs and downtime. You can invest the money you save with preventive maintenance back into your company’s infrastructure and staff.

For nearly a century, Quincy Compressor has been America’s leading supplier of air compressors and pneumatic tools. Since the 1920s, we have been at the forefront of innovation in air compressor technology. Today, our machines are in office buildings, repair shops, assembly plants and factories throughout the U.S. and abroad. Quincy Compressor troubleshooting services are thorough and dedicated, ready to help you with any maintenance needs.

At Quincy, we sell air compressors in a range of sizes to suit a vast variety of industrial applications. Find a nearby Quincy Sales and Service representative for more information or assistance with preventive maintenance.

Last Updated on June 28, 2023 at 12:05 pm

Table of Contents

- Difference between Preventive and Standard Air Compressor Maintenance

- Benefits of Preventive Maintenance for industrial Air Compressor Systems

- Recommended Preventive Maintenance Checks

- How to Create and Follow a Preventive Maintenance Check Schedule

- Which Maintenance Checks Should a Technician Perform?