The effects of climate change have many scientists and technologists looking toward the future with renewable energy sources in mind. Solar and wind power systems are an eco-friendly energy option, but they are dependent upon certain weather conditions to operate at full capacity.

Energy storage systems are one solution to this problem and can easily increase a power plant’s output and efficiency. One such storage system uses compressed air to save electricity for when it is needed. The idea of energy storage using compressed air has been around for decades but is recently being explored more as a solution to augment renewable energy systems.

What Is Compressed Air Energy Storage?

Compressed air energy storage, or CAES, is a means of storing energy for later use in the form of compressed air. CAES can work in conjunction with the existing power grid and other sources of power to store excess energy for when it is needed most, such as during peak energy hours.

Wind power is one example of how this works perfectly with other types of energy production. The wind turbines spin around to produce energy any time there is wind available, but the electricity it generates may not always be needed at the moment it is being produced, and thus, is wasted.

Alternatively, peak energy demand may occur at a time when there is not enough wind to spin the turbines and create sufficient energy. Stored energy of compressed air can be used to save the excess energy produced by the wind turbines, so it is available during peak energy times or when there isn’t enough wind to power the turbines.

How Does Compressed Air Energy Storage Work?

With compressed air energy, the electricity produced by other power sources, such as wind turbines, is converted into highly pressurized compressed air and stored for later use. When the energy is needed, this compressed air is then released into turbine generators so it can be used as electricity again. With compressed air energy storage, the energy can be stored — and later used — at any time of the day or year, regardless of weather or other conditions.

Air compression creates excess heat, and the decompression process removes heat from the air. There are three main ways of dealing with the compression and decompression process:

- Adiabatic: In an adiabatic energy storage system, the heat produced during the air compression process is kept, and then released out into the air during the decompression of the stored air. The heat can be stored in solids like concrete, or fluids like oils or molten salt. Currently, adiabatic storage systems are more theoretical, and have no major utility-scale applications in place yet, although they are expected to have a very high-efficiency rating.

- Diabatic: Instead of storing the heat during the compression process, a diabatic storage system uses intercoolers to dissipate the heat into the air as a waste product. As the heat is wasted, when the compressed air needs to be decompressed to release from storage, additional heat must be added. Natural gas is often used for the re-heating process and contributes to a lower efficiency of the power plant system overall. In a diabatic storage system, the air temperature can be used to gauge the volume of air remaining in storage. Although diabatic storage systems tend to be less efficient, they are the only type that has been implemented at a commercial or utility level so far.

- Isothermal: An isothermal storage system is the ideal that other systems attempt to attain. Isothermal systems are mostly theoretical but can be applied in very small scale systems with highly efficient equipment. These systems achieve a perfect or near-perfect heat exchange with the surrounding environment, but as of yet, have not been in practice for large scale CAES systems, as a certain degree of heat loss is unavoidable.

Compressed air can often be stored in existing and natural geological formations like reservoirs in rock or salt mines. Using existing infrastructure such as these can also keep costs lower. There are two main types of storage that can be utilized in a CAES system:

- Constant volume storage: In a constant volume storage system, specific physical boundaries control the volume of the storage space, but the air pressure of the space is variable. These systems need to maintain certain maximum pressure thresholds to avoid damage to the storage vessels. Examples of constant volume storage include natural options like abandoned mines, salt caves and old natural gas reservoirs, as well as man-made systems like above-ground pipelines.

- Constant pressure storage: A constant pressure storage system maintains constant air pressure, while the volume of the storage is variable. These systems generally utilize huge bags for the air to be stored in and are placed deep in the ocean, to make use of the ocean’s hydrostatic pressure. The constant air pressure allows for greater efficiency of the turbines and the power plant itself. These systems are more costly due to the placement of the storage units, but they also open up possible locations for CAES systems.

The Cost of Compressed Air Energy Storage

Compressed air energy storage can be an affordable method of energy storage, easily keeping pace with other competing methods, like pumped hydropower, electrochemical, thermal energy, gravitational and lithium battery storage. Some of these other energy storage systems work well for small-scale energy usages, such as electronic devices or vehicles, but for large-scale energy grid usage, CAES is one of the best.

The capital cost of using compressed air energy storage is around $1,500 per kilowatt and is considered relatively affordable when compared to other energy storage systems. Often, the installation and implementation costs are also low because existing and natural reservoirs can be used, and the technology and equipment are similar to what utility companies and workers are accustomed to using already. This keeps added construction, equipment and training costs down.

A CAES system also has the added value of increasing the output of the existing energy-producing facility. Storing the energy from variable sources like solar and wind power means the overall output of such facilities is drastically increased, putting them on par with larger, but less environmentally friendly options, like coal power plants. With added benefits like these, it’s difficult to calculate the total cost savings, but it’s easy to see that CAES systems are a viable and competitive option for today’s energy needs.

The Efficiency of Compressed Air Energy

Sustainability and the environment are leading concerns in the energy production and storage industries, and changes to the systems and new developments will favor higher energy efficiency and sustainability. The overall efficiency level of CAES systems can vary and will depend largely on the design of each individual facility.

Compressed air energy storage efficiency is lower than other methods and systems, like pumped hydropower plants and chemical battery solutions. This is because of the nature of the energy loss from compressing and decompressing air. As air is compressed, it heats up, creating wasted heat and energy that is released into the atmosphere. As the air is later decompressed, it cools down, which results in a lower energy output overall. Some systems use natural gas to heat the air before it is decompressed, but this also leads to lower overall energy efficiency.

However, even with these efficiency challenges, compressed air energy is often a better choice overall than many other energy systems because it requires no rare or toxic materials to operate and is not wasting non-renewable resources. CAES systems also do not require complicated technology to operate and are easy to maintain. The type of storage system for compressed air energy can have a huge effect on its overall efficiency and new technological advances are constantly being made to improve efficiency issues.

One way that CAES systems can be made more energy-efficient is through the use of water-filled reservoirs. When the compressed air is pushed into storage, water is pushed upward toward the surface level. The water goes back down when the compressed air is later used as energy. This system of pipes and water reservoirs maintains constant pressure for the stored air and improves overall energy efficiency.

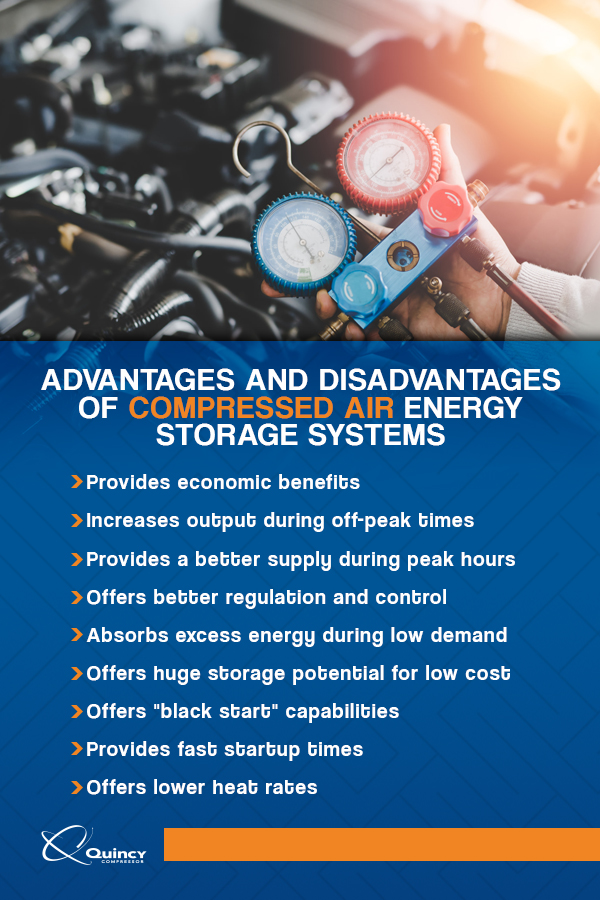

Advantages and Disadvantages of Compressed Air Energy Storage Systems

How is compressed air helping the environment? Compressed air energy storage systems provide many benefits, like adding to the overall output of an energy grid. Let’s take a look at some other key advantages of using CAES systems:

- Provides economic benefits: Owners and operators of power generation systems can see greater financial returns when CAES is used to support existing power facilities. The increase in power generation output means more money for the power companies.

- Increases output during off-peak times: During the nighttime and any other off-peak hours when demand is lower for energy, a CAES stores up energy for the next day or another time when demand is higher. The facilities can be used even when the demand is lower.

- Provides a better supply during peak hours: A CAES system has a much better capacity to handle peak hours and higher demand times with the energy it stores. It’s also better equipped to handle ramped up and intermediate energy needs, and can store nighttime energy to be used during higher-priced daytime hours.

- Offers better regulation and control: A CAES system provides much better regulation and frequency control than a base power plant could offer.

- Absorbs excess energy during low demand: When quickly decreasing energy demands drive prices of energy from other sources like hydro, fossil fuels or nuclear incredibly low, a CAES can absorb some of the excess and store it for later.

- Offers huge storage potential for low cost: Currently, no other energy storage system can provide the large capacity potential of which compressed air storage is capable. CAES systems can hold a much larger amount of energy than any other storage system and has a huge amount of flexibility for storage sizes and overall load management capabilities.

- Offers “black start” capabilities: In the event of a power failure, many other energy generation and storage facilities need a small amount of external electricity to get back up and running. CAES systems have black start capabilities, meaning they are able to restore operations without any external power supply.

- Provides fast startup times: These power systems can quickly start up from cold in a matter of minutes, much quicker than other power generation systems.

- Offers lower heat rates: CAES systems have much lower heat rates than other types of power generation systems. This means they are much more efficient for ramping, partial loads and regulation.

Of course, with any list of pros and cons, the disadvantages need to be explored as well. With compressed air energy storage, it seems the benefits outweigh the disadvantages. However, we are still not seeing the growth and implementation of new CAES for the following reasons:

- Limited site selection: Because CAES systems need certain types of existing geological formations, such as old salt mines or caverns or expensive pipeline structures, their potential site locations are somewhat limited. However, this may be more of a perceived disadvantage, because it’s estimated that around 70% of the earth’s landmass could potentially support CAES systems.

- Perceived risk: Some utility companies are uncomfortable with the idea of storing compressed air underground, despite the fact that fossil fuel industries have been storing natural gas and other hydrocarbon-based fuels in very similar conditions for more than 80 years.

- Inevitable energy loss: A certain amount of energy will be lost using a CAES system, especially during the compression and decompression processes. This loss is less than what would be lost without any energy storage system in place — however, the overall output is still greater with a CAES system due to the huge capacity for stored energy.

- Additional heating requirements: Some added heat must be used to expand the compressed air when it is ready to be used, which generally requires energy generated from other sources. This can be a problem, especially if fossil fuels are used for this purpose. Costs of other fuel sources, especially fossil fuels, can vary wildly over time and seriously cut into any cost benefits of a CAES system.

What Countries Are Currently Using CAES Systems?

Only a handful of utility-level and operational CAES systems exist around the world. However, from these few existing CAES systems, much has been learned about how they have the potential for better energy efficiency and applications all over the world. The two main operational CAES systems are in Germany and the U.S., but many other countries have startups and organizations studying CAES systems and are planning to construct more of them.

CAES in Germany

Germany has the proud distinction of constructing the world’s very first compressed air energy storage plant. Located in Huntdorf in Lower Saxony, Germany, this power plant seems far ahead of the curve and has been in operation since 1978. Here, the CAES system utilizes two huge cylindrical salt mines as the storage vessels and is used in conjunction with a nuclear power plant, helping with peak-load electricity. The CAES in Germany helps provide a much larger overall output of energy for the grid, but the CAES itself has relatively low efficiency.

CAES in the U.S.

The world’s second operational CAES system is in Alabama. This CAES was commissioned in 1991 in the city of McIntosh, Alabama and has a slightly better efficiency rating than the CAES in Germany. This plant is the only utility-scale CAES in the United States and uses a large salt cavern for the compressed air storage. The CAES power plant in McIntosh is integrated with a natural gas power plant and is able to increase the overall energy output from natural gas, making it slightly more environmentally friendly.

CAES in Canada

Located in Ontario, Canada, a startup venture called Hydrostor is experimenting with compressed air energy storage and is working to make CAES more economically viable. Hydrostor has also partnered with an oil and gas company, Baker Hughes, which sees the importance of diversifying and moving away from a sole reliance on fossil fuels. Hydrostor currently has one pilot CAES project up and running in Ontario where they can test out the whole system and several more projects in various stages of development in Canada, Australia and the U.S. They hope they can build bigger and better CAES plants, learning from their pilot project.

The Future of Compressed Air Energy Storage and Potential Impact on the Environment

With so many startups and organizations looking into compressed air energy storage and where it can be used, the future for CAES systems looks bright. We can expect to see more of these energy storage systems augmenting existing power plants. Increasing energy demands and interest in more sustainable models of energy production leave the door open for solutions like compressed air energy storage.

The near future will likely see an increase in the construction of new CAES systems and better efficiency within each system. As researchers study existing CAES systems, they find solutions for making them run more efficiently. As the technology for CAES usage improves, it will likely be an important tool to meet the growing energy needs across the globe in a more affordable and ecological way.

We may also see new and unique storage methods used in CAES systems, beyond just the salt mines or expensive pipelines. Scientists are also studying alternative storage vessels that could be used in the future. While salt mines and other natural caverns work very well as compressed air storage vessels, they aren’t available everywhere. One solution currently in research is using huge bags stored deep in the ocean. These bags would use the natural pressure of the ocean water to maintain the air pressure inside the bags.

Air Compressors and Supplies From Quincy Compressors

For the best air compressors, accessories and air compressor services, Quincy Compressor has you covered. For the past 100 years, Quincy Compressor has been a leader in innovation for all types and applications of air compressors. Our compressors and accessories are manufactured in the U.S. and follow the strictest of quality guidelines. Our long legacy of industry experience and quality means that you only get the best. We stand by our products and are proud to offer one of the best warranty programs in the industry, including quality replacement parts and service packages.

Contact Quincy today for more information, or find a sales and service location near you.

Table of Contents

- What Is Compressed Air Energy Storage?

- How Does Compressed Air Energy Storage Work?

- Cost of Compressed Air Energy Storage

- Efficiency of Compressed Air Energy

- Advantages and Disadvantages of Compressed Air Energy Storage Systems

- Countries Currently Using CAES Systems

- Future of Compressed Air Energy Storage