A Quincy air compressor is designed, engineered and built to provide many years of reliable service. You also get the benefit of industry-leading warranty programs for your protection and peace of mind, as well as 24-hour service via the extensive network of authorized Quincy dealers. What’s more, we also provide top-notch air compressor parts. We offer a wide selection of genuine Quincy compressor parts and air compressor fluid products so you’ll never have to worry about finding the air compressor parts you need to keep your compressor up and running.

Quincy Air Compressor Fluids

Rotary screw compressor fluids

Our rotary screw fluids provide excellent friction protection and extend bearing and rotor life. They also retain their viscosity at higher temperatures. Fluids are available for rotary screw compressors used in a wide range of light duty, heavy industrial and other applications.

- Genuine fluids

- QuinSyn Plus

- QuinSyn XP

- QuinSyn PG

- QuinSyn FG+

Reciprocating compressor fluids

We produce a wide range of reciprocating lubricants and fluids for varying conditions. These fluids can lengthen compressor life by protecting against heat, while also providing superior demulsibility in high humidity applications. They also meet OSHA guidelines for classification as non-toxic substances.

- QuinCip-D – 100% Synthetic

- QuinCip – Available in three ISO grades

Aftermarket fluids

Quincy aftermarket fluids have been proven to reduce energy consumption, waste disposal costs and MRO costs. By enabling your compressor to operate at peak efficiency and reliability, they can also reduce lost productivity, which will improve the health of your company’s bottom line. We offer a variety of aftermarket fluids and lubricants for specific applications and operating environments.

- QuinSyn Endura

- QuinSyn Edge

- QuinSyn Prime

- QuinSyn Flex

Genuine Quincy Parts

Inferior Products = Higher Service costs and reduced lifetime

Why Buy Genuine Parts?

- Increase Uptime

- Increase Efficiency

- Decrease Total Cost of Ownership

- Less Service Intervals

Risks of Not Buying From Genuine Sources

- Not getting genuine parts from authorized sources

- No warranty coverage or support

- No payment terms

- No technical support

- No credibility

- Increase in Total Cost of Ownership

Quick Facts:

- A pressure drop of less than 15 psi over the separator will increase energy consumption by 7%.

- Every 0.5psi of pressure drop over the air filter will decrease the compressor output by 2%

- A clogged filter restricts flow of your compressor and increases energy consumption by up to 4%.

Facts and Case Studies:

- Using another compressor to compensate for the capacity loss created by an imitation filter will add to power consumption and cost. For example, losing 5% capacity on a 100 HP compressor rated at 500 cfm will amount to 25 cfm. To compensate for this loss, another 7.5 HP compressor is needed, raising electricity costs by more than $6,707 per year. So, the real solution is to use Genuine Quincy Air Filters.

- The actual cost of a low-quality filter could easily exceed $7,700 per year for a 100 HP compressor. Add the risk of premature airend failure from ingestion of excessive foreign solids and it becomes clear that imitation elements cost more than their advertised savings.

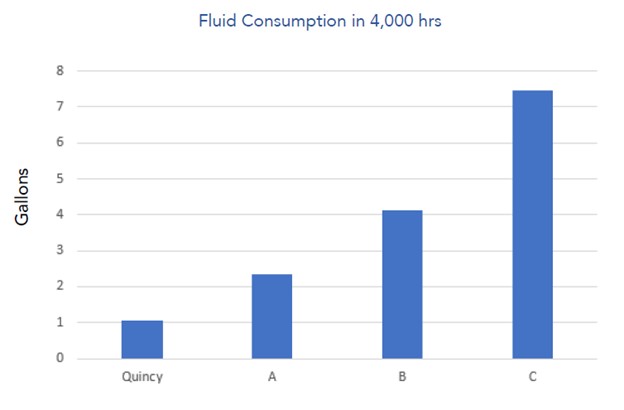

- A test conducted in accordance with ISO 8573 standards included four separators from different manufacturers. The samples “A”, “B” and “C” were from imitation suppliers who offer “interchangeable” elements. Fluid carryover for each separator was measured for 4,000 hours of operation, which is considered the life expectancy of the element. The results clearly show the performance of the Quincy separator reigns supreme.

Quincy Compressor Fluids

BASE OIL + PRECISE COMBINATION OF ADDITIVES = WINNING LUBIRCATION

Why Buy our Oil?

- Prevent rust & particles, which keeps your airend from locking up

- Maintain lubricity

- Ensure you avoid issues that lead to start-up problems

- Minimize energy consumption

- Ensure reliable performance

Key Feature and Benefits:

|

|

|

|

|

|

|

About Our Fluids

Quincy’s fluid analysis program is offered to all customers using QuinSyn fluids in our rotary screw compressors. This service provides optimum drain intervals for compressors operating on QuinSyn fluids. Monitoring the total acid number (TAN), barium level and viscosity throughout the fluid’s life provides maximum protection to your machine while best utilizing QuinSyn’s extended life features.

The fluid analysis provides historical information, detailing hours on the fluid, viscosity and TAN. Should results appear unusual or suspicious, a detailed analysis can pinpoint specific contaminants. A detailed report is furnished to you, your Quincy Distributor and the Quincy Compressor factory upon completion of the fluid analysis.

Although QuinSyn fluids are rated by hours of life expectancy under normal operating conditions, fluid samples should be taken every 500 to 2,000 hours and sent to Quincy Compressor Fluid Analysis until a history of performance in a specific compressor application is established. Once the appropriate drain interval is established, fluid analysis frequency can decrease unless operating conditions change.

QuinSyn Plus

QuinSyn Plus is the factory fill for Quincy rotary screw compressors. QuinSyn Plus is an ISO 46 viscosity fluid with an 8,000-hour life under normal operating conditions. It is a synthetic hydrocarbon/ester fluid. QuinSyn Plus is for use in compressors operating in harsh service conditions where the fluid is exposed to higher temperatures for extended periods.

| Typical Properties of QuinSyn Plus | ISO 46 |

| Viscosity @100°F ASTM D445 | 46.0 cSt. |

| Viscosity @210°F ASTM D445 | 7.5 cSt. |

| Viscosity Index ASTM D2270 | 127 |

| Specific Gravity 60/60 | 0.89 |

| Flash Point ASTM D92 | 475°F |

| Fire Point ASTM D92 | 540°F |

| Pour Point | -58°F |

QuinSyn PG

QuinSyn PG is a custom blended polyalklene glycol/ester (PAG) and an ISO 46 viscosity fluid with an 8,000-hour life under normal operating conditions. QuinSyn PG is the recommended fluid in high-humidity applications due to its ability to hold water. QuinSyn PG is best suited for applications where high humidity exists and the machine cannot be shut down to drain water from the reservoir.

| Typical Properties of QuinSyn PG | ISO 46 |

| Viscosity @ 100°F ASTM D445 | 52.4 cSt. |

| Viscosity @210°F ASTM D445 | 9.4 cSt. |

| Viscosity Index ASTM D2270 | 163 |

| Specific Gravity 60/60 | 0.98 |

| Flash Point ASTM D92 | 485°F |

| Fire Point ASTM D92 | 525°F |

QuinSyn XP

QuinSyn XP is the factory fill for high-pressure units over 150 pounds per square inch gauge (psig) full flow. QuinSyn XP is a custom blended polyolester (POE) fluid suited for rotary screw air compressors. It’s an ISO 68 viscosity fluid with a 12,000-hour life at 100 and 125 psig full flow under normal operating conditions and 8,000 hours as a high-pressure fluid. It’s designed for applications where the fluid endures elevated temperatures for extended periods.

| Typical Properties of QuinSyn XP | ISO 68 |

| Viscosity @ 100°F ASTM D445 | 43.0 cSt. |

| Viscosity @ 210°F ASTM D445 | 7.5 cSt. |

| Viscosity Index ASTM D2270 | 139 |

| Specific Gravity 60/60 | 0.83 |

| Flash Point ASTM D92 | 495°F |

| Fire Point ASTM D92 | 560°F |

| Pour Point | -76°F |

QuinSyn FG+

QuinSyn FG+ is Quincy’s food-grade fluid for applications where there may be incidental food contact. Compliant with FDA 21 CFR 178.3570 (Lubricants with Incidental Food Contact), QuinSyn FG+ is USDA-authorized with an H-1 rating for federally inspected meat and poultry plants. Since the fluid is a possible indirect food additive, the limit for food contact is 10 ppm. Near-white and low-volatility, QuinSyn FG+ is ideal for clean service.

| Typical Properties of QuinSyn FG+ | ISO 46 |

| Viscosity @ 100°F ASTM D445 | 42.0 cSt. |

| Viscosity @ 210°F ASTM D445 | 7.6 cSt. |

| Viscosity Index ASTM D2270 | 150 |

| Specific Gravity 60/60 | 0.85 |

| Flash Point ASTM D92 | 495°F |

| Fire Point ASTM D92 | 518°F |

| Pour Point | -58°F |

QuinSyn Flush

QuinSyn Flush is a specifically formulated synthetic fluid that dissolves varnish and solubilizes sludge from lubricating systems while in operation. QuinSyn Flush contains oxidation and rust inhibitors and can be used as a short-term fluid with a maximum of 500 hours. It’s fully compatible with mineral oils and QuinSyn synthetic fluids and is highly recommended as a flushing fluid when converting to QuinSyn PG from QuinSyn Plus or QuinSyn XP.

| Typical Properties of QuinSyn Flush | ISO 68 |

| Viscosity @ 100°F ASTM D445 | 43.3 cSt. |

| Viscosity @ 210°F ASTM D445 | 5.6 cSt. |

| Viscosity Index | 65 |

| Specific Gravity 60/60 | 0.965 |

| Flash Point ASTM D92 | 444°F |

| Fire Point ASTM D92 | 520°F |

| Pour Point | -45°F |

Benefit From an Air Compressor Pump Rebuild Kit

Getting air compressor parts you need is as easy as contacting the authorized Quincy Compressor dealer in your local area.

Only Quincy fluids and oils are approved for use in Quincy Compressors and Vacuum Pumps. These high-performance products have also been field tested and approved for use in other OEM brands of compressors.