As nations outside the G8 develop local industries to compete regionally and internationally, the use of air compressors is rapidly spreading throughout the Far and Middle East, as well as through much of the Southern Hemisphere. Over the next decade, these territories could quickly become the hottest markets for manufacturers of air compressors.

Compared to the developing parts of the world, industrial air compressor trends are more lukewarm in North America and parts of Europe. As recent industrial air compressor market analysis indicates, the issue comes down to economic factors. Regardless of which regions are leading the way in the industrial air compressor industry report, the technology continues to improve for users in a vast range of industries.

Why the Industrial Air Compressor Market Is Evolving and Changing

The market for air compressors has dramatically expanded in recent years as increasing numbers of manufacturers throughout the world discover the technology’s vast potential. Even as sales of air compressors slow in some of the most developed parts of the world, countries in the developing world are picking up the slack. The following factors drive market trends for air compressors:

- Technological innovation – The main catalyst behind the growing popularity of air compressors is the innovation that goes into newer models on the market. As manufacturers release new lines of reciprocating and rotary screw air compressors, the machines become more robust, easier to operate and better equipped for some of the most demanding applications across a range of industrial uses. As the technology continues to advance, more industries are harnessing the potential of compressed air as an energy alternative.

- Replacement demand – Another driving force behind the ever-expanding market for air compressors is the demand among customers for newer and better machines. As the technology behind air compressors improves, users of air compressors trade up their equipment for newer models. New and improved technology leads to boosted efficiency, greater ease of use and overall savings in operating costs. These qualities compel users of air compressors to replace their machines regularly.

- Industrialization – In the developing world, industrialization has driven an upsurge in sales of rotary and reciprocating air compressors. In towns and cities throughout Asia, Africa and South America, an increasing number of manufacturers are using air compressors. Currently, some of the hottest markets for air compressors are China, India and South Africa, where industry experts predict usage of the technology to soar over the next decade. Air compressors will likely spur automation in those developing economies.

- Investments – The air-compressor market also owes some of its growth to increased investments in urban development and the spread of manufacturing plants throughout some of the world’s developing economies. In countries like India and China — where many of today’s most common household items get mass-produced for global export — compressed air continues to grow in popularity as more manufacturers come to recognize its potential as an eco-friendly alternative to electricity.

In economic downturns, sales of air compressors are less likely to witness significant gains in some of the world’s more developed markets. Nonetheless, the technology will always have thriving markets as long as there are developing countries eager to compete with the industrialized world.

Changes in Industrial Use and Industries That Have Had Rapid Growth in Using Compressors

Air compressors are a leading source of power for many of the world’s leading manufacturers. Throughout the industrial, government and military sectors, compressed air plays a vital role in the movement of processes. Air compressors have witnessed exceptionally high growth in the automotive, chemical, food and beverage and oil and gas industries, where compressors help carry out the following functions:

- Power generation – Compressed air generates power for a vast array of industrial applications. At assembly plants, air compressors power the robot arms that assemble machines and parts. Many of the products you see on the shelves of computer and electrics stores would not exist without air-powered equipment. With compressed-air technology, manufacturers can more easily assemble tiny parts and also lift more massive pieces of equipment along assembly lines.

- Auto assembly – Air compressors are the driving force behind the process of auto assembly. At car manufacturing plants throughout Asia, Europe and North America, workers use air compressors to operate the machines that assemble engine parts and auto-body frames. Along the production lines, air compressors power the arms that set fasteners into place and put the upholstery on interior parts. At the end of the production line, air compressors power the spraying tools that paint and finish the outer bodies of newly assembled automobiles.

- Food and beverage packaging – Compressed-air technology is the secret behind the packaging and bottling of most of the foods and beverages you find on the shelves at supermarkets. For example, pneumatic suction and wrapping tools along conveyor belts help workers wrap packaged meats in airtight packages. Air compressors also power the machines that mold and clean cans, which then get shipped to food factories where workers fill, seal and label them with different arrays of pneumatic-powered equipment. A similar process occurs with the bottling of beverages.

- Chemical production – Thanks to the power and capabilities compressed air technology provides, chemical manufacturers can produce dangerous, yet necessary, chemicals without exposing factory personnel to noxious fumes and gases. At chemical plants, air compressors drive the machinery that mixes and measures the ingredients that comprise the chemicals in paints, adhesives, fuels and cleaning products.

- Oil and gas – With air compressors, the fuel industry can refine fuels with greater efficiency to meet the global market demand for gas and oil. As one of the world’s most vital resources, fuel is in constant demand, regardless of the economic climate in any given region. Fuel companies use air compressors to perform a range of vital tasks at production facilities throughout the world. Today’s sophisticated compressed-air technology allows oil and gas companies to implement processes without exposing work staff.

- Aerosol products – Pneumatic-powered machinery makes aerosol product packaging possible. An arsenal of air-powered tools contains these gases into airtight cylinders, ensuring no leakage or dilution occurs during the process. As the developing world grows more competitive on a global scale, companies throughout the Southern Hemisphere are now using air compressors to produce these products locally for domestic and overseas markets.

- HVAC systems – Compressed air is vital to the comfort of America’s large buildings and the sanitation of pressing plants. In business buildings, supermarkets and apartment complexes, compressed-air technology helps adjust indoor temperatures to ideal settings. As seasonal conditions become more extreme across various regions, the importance of compressed air in HVAC grows increasingly vital. Air compressors also purify the air inside factories.

- Pneumatic tools – Air compressors large and small power a vast array of tools for factory and personal use. In large production facilities, air-powered tools perform various minor details along production lines, such as the fastening of parts and the finishing of exteriors. At auto repair shops, pneumatic tools fasten and unfasten engine components and underside parts on cars, vans and trucks. Independent craftspeople even use pneumatic tools with portable air compressors.

The spread and development of air compressors have reduced the time it takes for manufacturers to mass-produce complex products and machinery. Taking a cue from the automotive sector and other forerunners in the trend, makers of various products have harnessed compressed air as a safe, low-cost, energy-efficient alternative to electrical power and manual labor for numerous processes.

Analysis of Changes in Compressor Technology or Types of Compressors

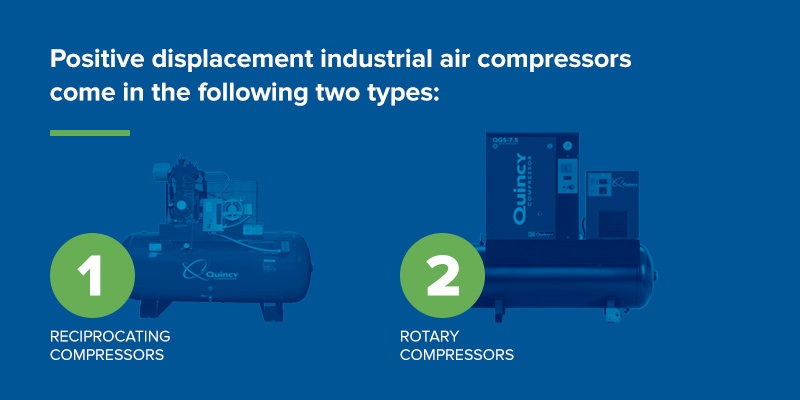

Air compressor design and technology have grown by leaps and bounds over the past couple of decades. As manufacturers strive to produce more efficient, quieter and longer-lasting units, many users of air compressors are eager to replace aging units with newer models. Some of the most popular air compressors are those in the positive displacement category. Positive displacement industrial air compressors come in the following two types:

- Reciprocating compressors – Also known as piston compressors, reciprocating air compressors use a piston to suck in ambient air through an inlet valve and pressurize it within a compression cylinder. The compressed air ultimately gets released for a variety of uses. Reciprocating compressors are available in large and small models and are standard tools at testing facilities and auto repair shops.

- Rotary compressors – Rotary screw compressors use counter-rotating rotors, typically with a five-lobed male rotor and a six-lobed female rotor. The counter-rotation draws in air, which becomes pressurized as it gets compacted between the interlocking lobes. Rotary screw compressors are indispensable in construction work, auto assembly and other applications that require air quality of a higher pressurization than a piston compressor could generally produce.

Some of the more demanding industries pass on positive displacement models in favor of dynamic industrial air compressors, which come in the following two types:

- Centrifugal compressors – A centrifugal compressor sucks air into a circular chamber with a center-rotating impeller, which pressurizes the air and sends it to a release valve for various uses. Today’s centrifugal compressors run on high-speed motors and are mostly oil-free, which makes this type of compressor a suitable option at facilities where the use of oil could be problematic.

- Axial flow compressors – An axial compressor passes incoming air through a chamber of rotating and still blades, which pressurize the air as the velocity increases during a given cycle. Axial flow compressors propel aircraft and generate electricity. They are also ideal for industries that require high speed and volume flow at moderate pressure.

Another distinction between different air-compressor models involves the use of oil. It all comes down to the type of seal on an air compressor. In this regard, we can divide the air compressor market into the following two categories:

- Lubricated industrial air compressors – Compressors that require lubrication tend to be heavier and more complex in their internal makeup. Consequently, units of this sort tend to require maintenance more often. On the upside, lubricated compressors generally last longer than oil-free models because the internal parts do not dry out.

- Oil-free industrial air compressors – Oil-free compressors generally require less maintenance than lubricated models because the internal makeup consists of fewer parts. Compressors that do not need oil are also lighter and therefore easier to transport. Even though such units are more convenient for a variety of uses, oil-free compressors wear down when the Teflon dries out. Consequently, oil-free compressors generally do not last as long as lubricated models.

Air compressors come in a variety of sizes and power capacities. The higher the kW, the more ideal the unit will be for high-powered operations. We can place the power range of today’s air compressors into the following four categories:

- Up to 50 kW – Air compressors in this range are small units that are generally in favor among craftspeople and at repair shops. Smaller compressors are available in portable and stationary models with vertical and horizontal designs. Compressors in this range are relatively affordable for hobbyists and smaller businesses.

- 50 kW-250 kW – Air compressors in this range are medium-sized units in frequent use among auto mechanics. Medium-sized air compressors are suitable for processes that require the use of handheld pneumatic tools, such as for repairs or parts assembly. Units in this range are reasonably priced and easy to fit into modest-sized workspaces.

- 251 kW-500 kW – Air compressors in this range are large units that are common at factories and pressing plants. The larger the unit, the more capacity it has for a broader range of simultaneous usages. Units in this range are ideal at assembly plants where machine arms do some of the heavier lifting, and human workers handle the finer tasks artificial intelligence can’t manage.

- 500 kW and above – Air compressors in this range are giant units capable of some of the most massive, demanding tasks. These huge air compressors often power HVAC systems in skyscrapers and operations at power plants. Units in this range consume lots of floor space and are often in designated rooms of their own.

Overall, the power range of air compressors on today’s market makes it possible for users of all needs and magnitudes to use the technology for numerous applications.

Indications of Where the Market Is Heading in the Next Decade

In the five years between 2016 and 2021, industry researchers project the global market for air compressors will grow by nearly 30 percent, from $25.71 billion in 2016 to $34.87 billion by 2021. The trend is the result of industrial growth in developing parts of the world where up-and-coming manufacturers are vying to compete on a domestic and international scale.

The International Standardization Organization and its policies on product improvement have further spurred demand for air compressors. Globally, sales forecasts for air compressors break down as follows:

- North America – According to recent market estimates, U.S. and Canadian sales of air compressors have largely plateaued for the time being, due to business roadblocks in some of the technology’s key industries. As America’s leading manufacturers consolidate their grasp on domestic consumers, fewer competitors emerge to boost sales of air compressors.

- Europe – Europe has long been a reliable market for air compressors. Despite this, there are mixed sales forecasts throughout the continent, due to shaky economies in certain countries. In some of the more robust parts of Europe, sales of air compressors will almost definitely remain steady. The situation is less certain in countries facing social upheaval and economic turmoil.

- South America – In specific parts of South America, experts expect sales of air compressors to rise as industrialization expands throughout these territories. As countries like Brazil, Argentina and Chile become more globally competitive, sales of air compressors could skyrocket in tandem with the opening of new factories and pressing plants.

- China – As one of the world’s most swiftly emerging markets outside the G7, China has been an avid consumer of compressed-air technology. The trend is likely to continue as industrialization expands and competing entities arise throughout the nation of 1.3 billion. China’s commitment to regasification has been a driving force behind sales of air compressors in that country.

- India – As with China, India has become one of the most formidable markets outside the G7. Though not as well-known as an exporter of products, India has witnessed vast industrial expansion in recent years, and these developments have spurred demand for air compressors among local manufacturers. India has also been home to a rising number of regasification facilities.

- Africa – As Africa becomes more industrialized, the use of air compressors has increased in select parts of the continent. The trend is most pronounced in South Africa, which — along with Brazil, China, India and Mexico — got invited to participate in the short-lived G8+5 during the mid-2000s.

In the emerging markets, sales for air compressors could either rise, fall or plateau beyond 2021, depending on the performance of manufacturers in the developing world that use the technology. Concerns over noise pollution could also inhibit sales in areas where this issue is a problem.

Buy New Air Compressors From Quincy Compressor

Air compressors have facilitated modern-day supply cycles for decades. As the world becomes more populated and product demand increases in vast quantities across all corners of the globe, air compressors provide the speed and power necessary for the production of foods, furnishings, electronics, appliances and automobiles for consumers in all nations. Now that the Second and Third Worlds are developing their own industries, compressed-air usage is more popular than ever.

For more than 90 years, Quincy Compressor has been the leading maker of air compressors in a range of designs and power capacities. We build our compressors for a variety of uses, from independent craftspeople to international corporations. Whether you operate a small repair shop or a large industrial facility, our compressors could power your tools with greater precision and efficiency.

At Quincy, we sell lubricated rotary screw air compressors in a range of sizes and capacities, from the 5 to 30 HP QGS to the 40 to 200 HP QGV® models. We also sell several lubricated piston air compressors, including single-stage, two-stage and climate-control models, as well as a range of oil-free air compressors.

To stay competitive in today’s industrial sector, manufacturers require high-tech facilities equipped with advanced tools and machinery. Quincy Compressor sells compressors and tools designed for some of the most demanding applications on the production front. Browse our catalog and contact us today to learn more about our products and services.