Pressurized air is the driving force in a vast range of industrial applications. From production plants to auto-repair shops, air compressors power everything from robot arms to pneumatic tools. Many of these processes replicate functions that were once performed with conventional tools and human hands. For example, air-powered sanders, painters and dryers can complete the finishing touches on cars and furnishings with far greater speed and precision than was possible in the days before such technology. Without air compressors, modern-day automation simply would not exist.

As manufacturing costs skyrocket and industries seek to maximize productivity to meet the demands of a more densely populated and increasingly globalized market, companies are trying to cut their overhead costs at every level. For applications that involve pressurized air, the most effective way to cut costs is to use variable speed air compressors, which maximize efficiency and require less energy.

If you run a production plant with several compressors that each power multiple tools simultaneously, you could see significant savings after trading out one or more of those machines with a variable speed compressor. The same holds true if you run a repair shop where a compressor powers handheld pneumatic screws and wrenches. Companies of all sizes can seriously reduce their overhead costs with variable speed compressors, which offer regulated airflow for a full range of applications.

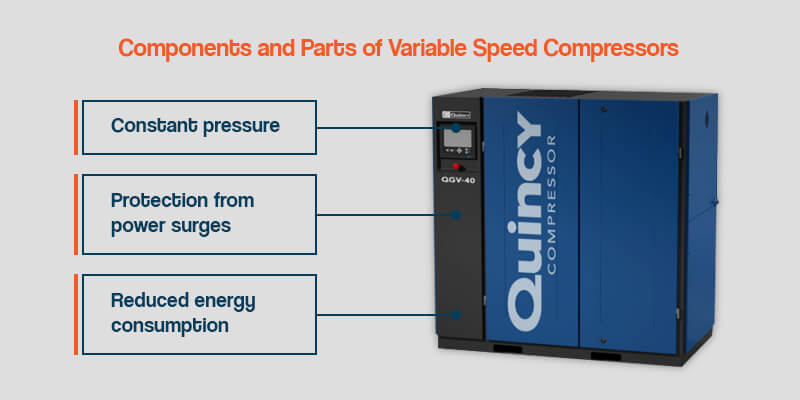

Components and Parts of Variable Speed Compressors

A variable speed air compressor is distinguished by a unique set of components that regulates the operating speed and helps users save energy. The key to the variable speed compressor is its special drive feature, which allows users to control the speed of airflow according to the needs of a project. The advantages of the variable speed design benefit users in several areas, including the following:

- Constant pressure: Variable speed air compressors deliver constant pressure as programmed by the user. When an application demands air pressure at an exact volume and consistency, the variable speed compressor will deliver this pressure without sputtering or wavering.

- Protection from power surges: A variable speed compressor will produce pressurized air at the exact rates and speeds that you specify in the settings. As such, you never have to worry about the compressor delivering a random pressure jolt and drawing excess power from an outlet.

- Reduced energy consumption: One of the greatest advantages of variable speed compressors is the reduced energy consumption that accompanies such models. If you install a variable speed air compressor at your facility, you could easily see your energy bills go down each month.

Thanks to the consistent pressure and efficiency of variable speed air compressors, most users save on energy costs and enjoy lengthier service durations with such models.

How Variable Speed Compressors Improve Energy Efficiency

A variable speed drive (VSD) regulates the frequency supplied to an air compressor’s motor in response to the demand on the system in real time. When the need for compressed air is low, the compressor motor operates at reduced speeds and requires less power. When the demand is high, the VSD automatically increases the air compressor’s frequency to meet system demands.

Conversely, a fixed speed compressor runs continuously at the same revolutions per minute (RPM) regardless of demand. Rather than adjusting the motor’s speed, a fixed speed compressor controls the air inlet valve to regulate cubic feet per minute (CFM) demands.

When a properly sized VSD compressor operates at lower speeds than the continuous rates of a fixed speed system, it uses significantly less energy.

Several ways a VSD compressor helps maximize energy efficiency include:

- Optimized power: One of the primary advantages of a variable speed compressor is that it ramps down RPM when the system demands change. Fixed speed compressors always draw the power amount needed to meet a system’s maximum demands. Depending on the amount of compressed air a facility uses and the variability between the processes, choosing a VSD system over a fixed speed compressor can deliver enhanced energy savings.

- Lower starting currents: Compressor motors with VSD controls require lower starting currents, eliminating the increased spikes that a fixed speed motor often causes when initiated. Variable speed compressors automatically control deceleration and acceleration levels to minimize amp peaks. VSD systems can also help avoid the potential penalties that power companies can impose for excessively high amp spikes.

- Compressor longevity: Variable speed motors optimize motor speeds and compressor performance. These factors reduce stress on the system’s electrical and mechanical components, prolonging your compressor’s life and minimizing downtime for repair or replacement.

- Tighter tolerances: Variable speed compressors use more advanced controls and operate on tighter tolerances than fixed speed models, translating to more consistent air discharge for all of a facility’s applications. These controls enable the compressor to run at lower delivery pressures while maintaining the minimal working pressure needed.

Remembering that these advantages depend on an operation’s specific compressed air needs and applications is critical. VSD systems aren’t the perfect choice for every facility. Variable speed air compressors offer the most significant cost savings for operations with the highest variation in their CFM requirements and those requiring the tightest operating tolerances.

The Quincy QGV Variable Speed Rotary Screw Air Compressor

Of all the air compressors on the market, the Quincy QGV variable speed rotary screw air compressor produces some of the most consistent air pressure. With turndown as high as 85%, the QGV features a flex-drive airend that allows the machine to function with maximum efficiency for up to 100,000 hours. As such, the Quincy QGV is easy to maintain and inexpensive to own and operate.

At a glance, the Quincy QGV variable speed air compressor features a heavy-duty intake filter that brings clean air into the pressure chambers. For applications that require minimal demand, the QGV can be set to accommodate these specifications, allowing you to save energy on projects that need consistent yet low amounts of air pressure. Overall, these features make it possible for the QGV to provide maximum performance with minimal power consumption.

The Quincy QGV is also relatively quiet for a variable speed air compressor, as the machine is built with an enclosure that restricts the passage of sound. Moreover, the internal parts operate with no friction and rarely require servicing. The basic specs of the Quincy QGV include the following:

- 82-982 cfm

- 75-150 psig

- 68 dBA and lower sound levels

Compared to other types of air compressors, the Quincy QGV is optimized for the highest levels of energy efficiency for the full spectrum of operations. Models in the QGV family are equipped with variable speed drives, which control the speed of the airflow to ensure that the compressor conforms to the output requirements of the application at hand. In doing so, the QGV offers an energy savings of 35% over regular rotary screw models.

The Quincy QGV is backed with a 10-year warranty, giving users the confidence that such an investment will ensure years of productive use for a wide range of applications.

Low Demand Mode

One of the best features of the Quincy QGV variable speed air compressor is its low demand mode, which ensures optimal efficiency through various operations. This feature eliminates the threat of rapid cycling, which could otherwise be a problem during applications where air demand is minimal. At times when the air demand drops under the turndown capacity, the low demand mode allows the pressure to surpass a set point before the unit is stopped.

The Quincy QGV’s low demand mode prevents unloaded operations in the air compressor. The low demand mode also guarantees that the pressure never falls to a level that would be harmful to the applications at hand. If the compressor is connected to a network of devices, the low demand mode ensures that the pressure is brought to a level that will cause the added pressures to shut down accordingly when demand reaches low points.

Capacity

While pressure is one of the most crucial specifications to note in the performance specs of an air compressor, the capacity of a given model is equally important. With air compressors, the capacity is also known as the volume of air that gets released per revolution. Therefore, while the air pressure correlates to the force or strength of the pressurized air supply, the air capacity refers to its volume.

When it comes to pressure, the options are more open because air compressors of all sizes can have identical pressure capabilities. For air capacity, however, the options are somewhat more limited because size does matter. Simply put, a larger air compressor will provide more air capacity. If your operations require large volumes of pressurized air per revolution, you will need to have a large variable speed air compressor.

Pressurized air capacity is expressed as cubic feet per minute (CFM). To determine the CFM requirements for the full range of processes at your facility, add up the total number of CFM requirements for each tool that you plan to run simultaneously and multiply that number by 1.5. In other words, if you typically employ three pneumatic applications at the same time that require 5, 10 and 15 CFM, you will need an air compressor with a capacity of at least 45 CFM.

Variable-speed drive machines are generally made to offer around 80% capacity. However, the Quincy Power$ync can provide maximum power and efficiency at even higher loads. On loads that exceed the standard 80% threshold, the Power$ync can best that efficiency by 10%.

How You Can Benefit From Energy Savings and Reduced Power Consumptions

The advantages of variable speed compressor models are quite numerous when you consider all the benefits of energy savings. If you run a large facility, a 35% reduction in energy consumption could help you drastically cut your monthly electrical bills and reduce your reliance on fossil fuels. In doing so, your facility could be at the forefront of environmentalism in the industrial sector. These benefits could have added advantages if you manufacture commercial goods, as your eco-friendly practices could boost your brand image in the eyes of the public. Overall, the benefits of variable speed air compressors can be broken down as follows:

1. Combat Climate Change

Thanks to all the parts and features that make variable speed air compressors more energy efficient than competing models, models like the Quincy QGV offer some of the most eco-friendly sources of pressurized air. As such, factories that use variable speed air compressors leave a smaller carbon footprint. When you set up a variable speed compressor at your facility, you will help to reduce emissions among your sector, combating climate change in the process.

2. Reduce the Cost of Facility Operations

Variable speed air compressors provide longer service cycles and generally experience fewer performance issues in the long run. On average, a variable speed compressor will only need to be serviced once every 100,000 hours of use. This, combined with the high efficiency of these units, allows you to save money as an owner and user of a variable speed air compressor. At the end of each financial year, these savings amount to lower operating costs for your facility as a whole.

3. Cleaner, Healthier Indoor Air

Variable speed air compressors are more efficient and environmentally friendly than competing models. The fact that such units use less energy and reduce the carbon footprint of a given work facility means a healthier working atmosphere for employees in enclosed spaces. Regardless of the size of your workforce, variable speed air compressors will help you maintain a cleaner atmospheric environment at your facility.

4. Own a More Durable Air Compressor

The internal components that comprise a variable speed air compressor are more durable than most competing models. Compared to a more conventional rotary air compressor, a variable speed compressor will perform day after day for months on end for upwards of 100,000 hours before it will need maintenance from a service technician. When you do the math, those hours could amount to several years of performance between each service cycle. Basically, an investment in one variable speed air compressor could pay itself back in spades through years of unabated service life and high-efficiency performance.

5. Pioneer the Future

With a variable speed air compressor, you get the satisfaction of knowing that your operations are among the lowest-emitting in the industrial sector. As such, you will be doing your part to help lead your industry and others toward a more eco-friendly set of applications and machine arsenals.

6. Full Range of Uses

Variable speed air compressors are applicable for a vast range of uses. If you need to power a set of pneumatic tools for high-volume productions and assemblies, a variable speed model can be set to handle the pressurization demands of each application. If your work requires pressurized air at precise speeds for delicate surfaces, a variable speed compressor can be programmed to meet those demands.

7. Enjoy Year Round Performance

When you add up all the costs that it takes to run a facility, the overhead can take a huge chunk out of your bottom line over each financial year. With a variable speed air compressor, you can cross out compressor maintenance from your list of expenses during a typical year because such machines rarely need to be serviced. Depending on how many hours per week you rely on pressurized air, service years might be as frequent as leap years.

8. Maintain a Healthier Work Environment

When you spend hours on end in settings where high-powered machines produce pressurized air for various applications, the effects on your health could be somewhat detrimental unless the machines in question are low-emitting and energy efficient. With variable speed air compressors, the working environment becomes healthier because the processes at hand generate cleaner air. As such, variable speed compressors can help you maintain a healthier facility.

9. Work and Operate in Relative Quiet

Variable speed air compressors are relatively quiet machines when compared to competing models. At facilities where dozens of processes occur simultaneously, any amount of noise reduction could be an asset for you and your staff. With variable speed compressors, the noise is contained by the design of the enclosure and further reduced by the regulated speeds and overall efficiency of the mechanisms within.

10. Lower Energy Bills

Energy costs can be one of the largest money drains for a workshop, factory or any other type of facility where high-powered machines are constantly in use. Air compressors can be particularly taxing on your energy supply, especially if you run pneumatic processes that require continuous, nonstop airflow. Thankfully, variable speed compressors require less energy than other models, allowing you to save on your energy bills and increase your bottom line.

11. Improved Public Image

If you run a commercial business in which products are manufactured with air-powered processes, any step you take toward energy efficiency could have a positive impact on your public image. As consumers grow more conscious of the environment, people are becoming more intent on supporting businesses that engage in eco-friendly practices. When it comes to processes that involve pressurized air, the most eco-friendly practice your company could engage in is the use of variable speed air compressors.

12. Less Reliance on Fossil Fuels

For pneumatic applications, the amount of power required to maintain a pressurized airflow can be highly consumptive of a factory’s energy supply. When you multiply the energy savings of variable speed air compressors at an hourly, daily, weekly and monthly rate, the 35% energy savings can really add up over each year. That savings could amount to a drastic reduction in your reliance on fossil fuels.

13. Low Maintenance Environment

When you run a pressurized air system where the airflow is precisely regulated and efficiency is maximized across the board, you will generally have a cleaner working environment. The largely maintenance-free workings of a variable speed air compressor translate to less maintenance throughout your facility, as you will not have issues with moisture, condensation and other side effects that accompany low-efficiency air compressors. As such, you are less likely to encounter wet, rusty machine parts across your factory floor.

14. Return on Investment

The money that you invest in a variable speed air compressor can easily be earned back in due time thanks to the productivity that such machines can produce. If you run the compressor continuously for many applications, the energy savings will quickly regain some of your initial investment in the compressor. Within a year, the accumulated energy savings could pay back a sizable chunk of the original price. If you use the variable speed compressor for commercial purposes, you could easily earn back the cost in only a small amount of time.

15. Protect Your Facility From Rising Electrical Prices

In recent times, the cost of electricity has been known to fluctuate. Depending on your peak hour usage, you could find yourself thrust into a higher payment bracket unexpectedly, even if that peak usage is only a rare occurrence. With a variable speed air compressor, your facility would be less susceptible to these unpredictable rate hikes because you would draw less energy while powering various pneumatic applications.

How You Can Potentially Qualify for Energy Efficiency Rebates

With a variable speed compressor, energy savings can translate to more than just lower monthly rates on your electrical bills. Certain state and federal agencies offer rebates to companies that purchase energy efficient equipment. For more information, check sites like DSIRE and Energy.gov to find out whether you can qualify for rebates in your area.

In today’s industrial sector, few of the processes that manufacturers have come to rely on would even be possible without compressed air. Automakers, for example, rely on air-powered tools at all stages of production. At the beginning of an assembly line, pneumatic tools are used to fasten together the parts that comprise the body of a car, van or truck. As these pieces move on down the line, air-powered robot arms lift heavier pieces and fit them into place. With variable speed air compressors, the various steps of auto assembly become more energy efficient and less costly for automakers.

Air compressors are also crucial in the construction of furniture. It would be impossible to produce the quantities needed for today’s market if technology were to revert to a time pre-dating pneumatic power. At furnishing plants, the parts that comprise a table, shelf, sofa or chair are passed along a conveyor belt and connected to one another with pneumatic screws and wrenches. Further down the line, newly assembled wood furnishings receive finishing coats by air-powered sprayers. Alternately, sofas and love seats are upholstered by pneumatic draping and fastening tools. All such processes can be applied most efficiently with variable speed air compressors.

Air compressors are also largely responsible for the packaging of products that you see on food and beverage shelves in supermarkets. At bottling plants, pneumatic tools and machines are used to mold bottles into shape out of hot glass formulas. Once the bottles are ready, they are then sent along conveyor belts to be filled to precise ounces and then sealed shut with machine-applied caps. The bottles are then passed along to be labeled with air-powered stamping and impression tools. If you run a manufacturing plant, you can save money on these and other processes by using variable speed compressors.

Get Variable Speed Air Compressors From Quincy

Quincy Compressor is a leading manufacturer of air compressors. Since 1920, we have provided quality air compressors to industrial companies around the world. Today, we sell variable speed air compressors like the QGV line of models, which are optimized for maximum efficiency, lengthy service durations and super-lower energy consumption. To learn more about how our variable speed compressors can transform your operations, contact Quincy today or find a dealer near you.

Last Updated on July 31, 2023 at 2:55 PM