Air compressors are used in robotics competitions to demonstrate how pneumatic power can work in automatic, pre-programmed, moving devices. You can use compressed air to move robotic arms and legs at measured lengths. The best compressor for robotics competition events is generally a small, portable reciprocating model.

Another benefit of compressed air is that you can easily replace the tubes that supply various robot parts with pressurized air when necessary. For example, if a mishap occurs that causes one of the joints to lose contact with the air tank, the problem can immediately be rectified by the engineers responsible for the robot. If the arms and legs were to instead rely on electronic components, repairs would be significantly costlier and more labor-intensive.

Robotics competitions are an excellent opportunity for high school students to learn about the process of robot construction and enter into contests that can ultimately yield huge scholarship rewards. For college students, robotics competitions offer the perfect opportunity to advance these skill sets and unveil new innovations in robot technology. Robotics contests are also important for professional organizations, which can submit new designs and mutually learn from the eye-opening ideas of competitors. Overall, robotics competitions are forwarding the march toward automation, and pressurized air is at the heart of these developments.

Contact Us Learn More Find a Dealer Near You

Why Air Compressors Are Used in Robotics Competitions

Pneumatic systems have long been employed in the industrial sector for everything from auto assembly to food packaging. With compressed air, manufacturers can assemble items in mass qualities for public use. One of the most crucial developments in pneumatic technology has been the development of robot arms, which are used at automotive factories to lift heavy parts and fasten pieces together into assembled components.

With air-powered robot arms, manufacturers can assemble cars and trucks with far greater speed and efficiency than would ever be possible with human hands. Best of all, manufacturers can cut down production costs with pneumatic tools and ultimately pass those savings down to consumers.

In robotics competitions, pneumatic power supplies are easy to assemble, even with little preparation time. Most functions will work on 60 pounds per square inch of air power. Pneumatic systems are also relatively lightweight and can easily be repaired, if necessary, on the same day as a competition.

The compact nature of pneumatic systems in robots stands in contrast to the cumbersome qualities of most electronic components, which are difficult to repair and tend to add more weight to a given device. Moreover, electronic components require numerous wires and bulky enclosures, regardless of whether the robotic device is remotely operated or plugged into a power socket.

Pneumatic power has been an important function of robotic competitions since the early days of such events back in the 1990s. As students entered their creations into these competitions, it quickly became obvious that pressurized air was a more effective, convenient and efficient fuel for robotic movement than electrical components or batteries.

It could easily be argued that pneumatic systems facilitated the rise of robotic competitions by making the technology easier to develop among enterprising minds at various skill levels. With air-powered arms and joints, these easily assembled robots have performed tasks that have expanded people’s perceptions of the potential for robot technology.

Over the past quarter-century, the technology involved in robotic devices has improved in tandem with developments in pneumatic systems. In recent years, the pneumatic systems on competition robots have become more compact and easier to assemble and regulate to appropriate pressure levels. As such, students who enter into these competitions are having greater success with their robots.

Pneumatic systems are used to power the movements of a vast range of competitive robotic devices, from remotely animated Lego creations to devices used to launch balls and pour liquids at exact measurements. In some cases, the robots exhibited at these events have gone on to serve as prototypes in the development of more advanced robots that are being tested today by various entities in the industrial sector.

How Air Compressors Are Used for Robotics Competitions

The biggest difference between pneumatics and electronics is the order of operation. In electronics, you have a positive and negative, whereas with pneumatics, you have a collection of tubes that simply function in the way you attach them to the robotic device in question.

The construction of a pneumatic-powered robot device is also relatively straightforward because you do not need to solder any panels or strip any wires. Moreover, the connections are easy to assemble in pneumatic systems. With an air-powered robotic device, you do not have to worry about whether a particular screwdriver will fit intothe socket of a particular screw because no such fasteners are involved in the overall construction.

The device that pressurizes ambient air for use as power in a robotic device is known as the compressor. During operations, the compressor can become heated to the point where neighboring parts can get damaged if the unit lacks sufficient ventilation and cooling capabilities. It is, therefore, crucial to have a robot’s pneumatic system equipped with a fan.

The compressor is also prone to vibrate. If placed too close to one of the crucial stationary features in a robotic assembly, the vibrations could defeat the purpose of the robotic functions. For example, if you design a robot to take pictures from odd and hard-to-reach locations, the pictures might come out blurred if compressor vibrations cause the device to shake while the photos are being taken. Therefore, the compressor should be placed at a distance from the camera component to prevent disruptive vibrations.

One of the most important components in a pneumatic system is the pressure release valve, which regulates the amount of pressurized air that travels from the compressor to the end-point application, which in this case would be the moving parts of a robotic device. If the moving functions get overloaded with air pressure, they could ultimately malfunction and cause the robot to fail while out on the floor during a competition. Likewise, the compressor could also overheat if the pressure is not regulated correctly. To adjust the pressure release valve, you simply move the rings that are threaded around the valve.

As a backup function to the pressure release valve, pneumatic systems are also equipped with a pressure switch. During instances where the pressure exceeds the maximum limit for the robot at hand, the switch activates automatically to shut off the compressor. In most robotic devices submitted to competitions, the maximum limit will generally be around 120 psi. If the pressure exceeds that level, the switch will trip and halt the transfer of further air power. To help prevent a robot from being overloaded with pressurized air during a competition, pressure limits should be set in the range of 80–110 psi.

To hold the air that ultimately gets used during the competition, each robotic device will usually be equipped with several air tanks. The purpose of each tank is to hold airfor later use. It is therefore essential to ensure each robot has as many of these tanks as is needed.

Robotic devices are also equipped with regulators, which limit the amount of air pressure that travels downstream to other components. This way, you can control the amount of pressure that gets sent to each part of a robot. If one area requires more pressure than another, you can have each piece regulated at different levels. For example, if one arm is required to lift heavier objects and move at twice the speed of other arms, that arm can be programmed to receive higher levels of pressure than the other components. With regulators in place, each robotic device can perform a wider range of different functions.

Another important feature on a pneumatic system is a pressure gauge, which allows you to read the level of pressure that generates inside an active air-powered robotic device. As the pressure rises, you can read its current level as indicated by the gauge. With pressure gauges, you can keep track of the current pressure level at any given time during a competition. If the pressure exceeds acceptable limits, you can adjust it to a more acceptable level. Pressure gauges help you avoid situations where high pressures might exceed the maximum limit and damage the device.

For the remote control of pneumatic devices, some of the most critical components are the solenoid valves, which work like transistors in a pneumatic system. When a solenoid valve is triggered, it adjusts the flow of pressurized air between corresponding ports. In some setups, solenoid valves can be adjusted in both directions. In other setups, an adjustment can only be made in one direction, meaning the valve will switch back to normal as soon as the signal disappears. For devices where speed is a top priority, it is best to have solenoid valves with large holes.

What Types of Robots Use Compressed Air?

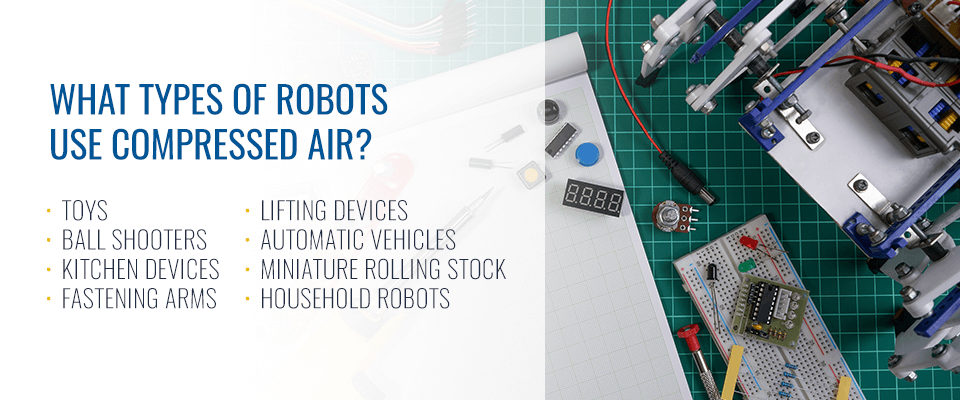

An air compressor for robotics competitions can power a multitude of technological innovations. At student events, some of the most widely seen examples of air-powered robotic technology are machines that allow for independent sporting and automatic lifting. For the tech industry and its many observers, robot competitions provide a window into the future of automation. Within the next two or three decades, the robots that you currently see at these competitions could become commonplace in everyday life. Some of the most popular categories of tech on display at these events include the following:

1. Toys

At robot competitions comprised of teenaged participants, air-powered toys are a popular theme. Some of these robots consist of Lego bodies that are built into Transformer-like characters. The arms and legs on these robots are moved and driven by pneumatic power. In the future, such toys could revolutionize the way that young people interact with their favorite characters in science fiction and comic books. The technology could also make the gaming world more realistic as participants compete in war games through these air-powered robot creations. For kids who lack playing partners, robot toys could offer a needed avenue of escape.

2. Ball Shooters

A popular concept among younger participants at robot competitions is ball shooting devices. For example, some events have exhibited robot devices that launch balls at nets and sometimes into basketball hoops. The goal is to see whether future sporting events will be able to incorporate remotely operated ball launches into the process. The technology could also be helpful for young people who wish to develop skills at a certain game. For example, a young person who wants to get better at baseball yet doesn’t have any practicing partners could use a robot device to launch the ball and practice the hit.

3. Kitchen Devices

Some of the most innovative robotic devices exhibited at competition events have been designed for kitchen use. Examples include robotic arm sets, powered by compressed air, that pour ingredients into bowls at measured quantities, as specified by the directions of a given recipe. These same arms then mix the ingredients to the desired consistency. Once the preparation is complete, the mixture can be poured into a cooking tray and heated. With kitchen-geared robotic devices, restaurants of the future could have largely automated kitchens. These developments could eventually extend to domestic use and likely be embraced as an alternative to manual home cooking.

4. Fastening Arms

Some of the more important innovations on display at many robotic competitions are fastening arms, which automatically fasten hard and heavy pieces at industrial facilities. At appliance factories, the technology has rendered the production process faster, more efficient and less costly. With robotic fastening arms, heavy and awkward appliance and furnishing parts can be fastened into place in a matter of seconds. In a few quick steps, entire units can be assembled, enclosure and all, in just a fraction of the time that it would take for human workers to complete such tasks.

5. Lifting Devices

Robot competitions offer a prime opportunity for technology developers to exhibit the latest innovations in robotic arms. The purpose of these arms is to do some of the heavier and more complicated lifting at industrial facilities. For example, in the field of auto assembly, a variety of large and heavy parts must be lifted onto conveyor systems and mounted with other large and heavy pieces. With pneumatic robotic arms, human workers are spared the strain of such heavy lifting. For especially heavy components, machinery powered by robotics is essential.

6. Automatic Vehicles

Another major innovation that is being unveiled each year at robot competitions is the automatic vehicle, which is exhibited in miniature prototypes that indicate the technology’s potential. As more people anticipate a future without gas-powered vehicles, the robot vehicles on display at these events serve as indicators of how the streets could possibly look within a few decades. Most importantly, these miniature models help demonstrate how vehicles could ultimately run on compressed air and potentially significantly reduce the world’s reliance on petroleum-based products. Moreover, these devices can also suggest the robotic features that will likely be included in these vehicles of the future.

7. Miniature Rolling Stock

Robot competitions have sometimes served as showcases for miniature versions of the rolling stock of the future. For example, vehicles that can lift dumpsters and haul lumber could one day operate without the help of human hands, as previewed in these robotic prototypes. Automatic rolling stock may include robot lifting arms and other features that could soon eliminate the human risks involved in trash collection and building construction. Thanks to the innovations being previewed at these events, there might one day come a time when skyscrapers will be built from the ground up by air-powered construction vehicles and robotic-arm attachments.

8. Household Robots

In the future, robots could become part of people’s families. At robot conventions, devices are often exhibited that have been programmed to perform specific everyday tasks, such as garbage collection and house cleaning. Within a few decades, American households of all sizes could each have one of these robots in-house to perform a variety of chores that people often neglect. The robots that are currently programmed to perform these functions will become more complex as the pneumatic systems that power these creations are developed in tandem with machine components and artificial intelligence.

Will the Role of Compressors in Industries Like Robotics Change or Adapt in the Near Future?

In the coming years, the role of compressors in the robotics sector will inevitably change as technologies advance and designs become more streamlined. With each passing year, these developments are on full display as students unveil innovations in the realm of air-powered robot devices.

Some of the most significant changes will involve the motion and design of robot designs. Whereas most of today’s robots are very machine-like in appearance and mechanical in motion, future robots will likely assume a more organic appearance and fluid set of motions. The challenge for current robot developers is to find ways to make the joints on these creations seem more natural and lifelike.

Increased competition within the industrial sector will spur on the advancement of robot technology and the role of compressed air within these developments. As the technology outpaces human ability, the companies that adapt will be able to manufacturer products in mass quantities without the inherent problems posed by human error. These early adopters will, in turn, benefit from increased sales and market saturation.

Overall, the development of air-powered robot technology should lead to the full automation of the auto-making and food-packaging industries. In due time, these developments should also reduce the need for human workers in building construction and military operations. Eventually, air-powered vehicles and robot technology will also replace the need for cars and commercial drivers as transportation and commercial delivery become fully automatic.

As pneumatic robot technology spreads into everyday life, the air will become cleaner due to the reduced emissions of a less fuel-dependent society. The spread of pneumatic power in the realm of automation and transportation will largely reduce America’s dependence on foreign oil and the need to drill.

With today’s rapidly advancing technology, increasing numbers of people are becoming aware of the benefits of compressed air technology. By harnessing air power, industries can streamline production while leaving a smaller carbon footprint. Meanwhile, people will be able to enjoy a wider range of products at reduced prices, thanks to the reduced costs of automated manufacturing.

Air Compressors and Attachments From Quincy Compressor

If robot competitions are any indication, the robot revolution is right around the corner. With so many young people submitting their own creations to these events, the technology is getting to the point where nearly any tech-savvy individual can create their own robot. In the coming decades, technological capabilities will rapidly improve in these areas, perhaps making it possible for people to create their own housekeeping robots and air-powered lifting machines.

In the meantime, you can find air compressors and pneumatic tools designed for today’s technology at Quincy Compressor, the leading name in compressed air innovation since the 1920s. Explore our catalog or contact us today to learn more about our air compressors.