Compressed air has long been the power of choice for American industries. Whether you are building cars or manufacturing toys, compressed air powered tools are considered more reliable and consistent than electrically powered tools.

However, compressed air also plays a special role in the medical and dental fields. Although both of these industries use compressed air to power tools, they also use compression in order to deliver breathable air to patients. Because of this particular application, medical and dental air compressors need to ensure air is pure and free of contaminants.

Quincy Compressor’s products serve a wide variety of industries. Medical compressed air applications are no exception. We have worked hard to ensure that our equipment, accessories and service and support for medical and dental professionals and administrators are suitable for assisting in providing excellent care.

Because medical air compressors are unique, we wanted to offer a guide to provide additional information about compressed air in medical and dental situations. Our goal is to demystify the many ways industrial compressed air systems can be used within medicine. So join us as we explore the specific applications of medical- and dental-grade compressed air, the regulations that govern these applications and among the best tools on the market for providing compressed air to patients.

Dental and Medical Compressed Air Applications

Contact Us Learn More Find a Dealer Near You

Let’s begin with an overview of the ways compressed air can be employed within the medical and dental fields. You will discover that compressed air applications vary widely and are a mix of long-held practices and new and innovative uses for compressed air. Regardless, it is clear that compressed air is an essential part of any medical or dental practice. The following are just a few of the popular applications for compressed air in the medical and dental field:

Resistance for Rehabilitation Equipment

Although equipment for physical therapy and rehabilitation is similar in form to work-out machines at the gym, free weights can prove dangerous for those recovering from serious injuries or ailments. That’s why many rehabilitation centers have turned to compressed air to provide the precise resistance required for medical-grade physical therapy. This allows therapists to delicately adjust resistance without running the added risk of moving weights by hand.

Stone Management

Recently, many doctors have turned to pneumatic lithotripsy, where compressed air is used to manage stones in the kidneys, bladder and ureter. This kind of precision application requires equally precise compressed air systems. For those who may be suffering from kidney or bladder stones, compressed air can provide much-needed relief.

Orthopedics

Calcaneal spurs, tennis elbow and patellar apex syndrome can all be treated with compressed air-supplied shock waves. This has proven to be a valuable treatment as it allows doctors to perform minor orthopedic treatment without the use of anesthetics.

Compressed Air-Powered Tools

Within the dental industry, compressed air-powered tools, whether they are used for cleaning, polishing or drilling, are essential. Because compressed air-powered tools are more reliable and easier to maintain, they provide a number of advantages over electrically powered tools.

Dental Air

Beyond powering tools, dentists also use compressed air directly within the cleaning and drying process. Compressed air is used to dry sections of the mouth in order to make dental hygiene processes easier.

Veterinary Work

As pet owners invest more in treatment for the animals in their lives, veterinarians are expanding their services. In turn, compressed air has become an increasingly important tool within veterinary clinics. Many of these applications are similar to those in the human medical fields, including veterinary respirators and injury rehabilitation.

General Precision Cleaning

Finally, within the medical and dental industries, there are certain processes that require precise cleaning, such as the preparation of dentures. Compressed air allows technicians to control the air flow of cleaning instruments while also performing actions without physically touching them.

As you can see, there are many applications for compressed air within various medical and dental fields. While this list is not exhaustive, compressed air continues to be a valuable tool in medical innovation. As medical professionals continue to work tirelessly to develop the next best treatment or device, undoubtedly compressed air will play a significant role in a sizable portion of them.

Medical and Dental Compressed Air Cleanliness Requirements

While there are many applications for compressed air within the medical and dental professions, the use of compressed air systems also requires a higher standard for air quality than any other industry. That’s because much of the compressed air used within both the medical and dental fields is ultimately used within the human body.

For dentists: in order to be both confident in the services provided to your patients and to remain compliant with NFPA 99 regulations, there are a number of things to consider when implementing a medical or dental compressed air system.

Let’s start with the NFPA 99 regulations. Developed by the National Fire Protection Agency, these standards are the current benchmark by which all medical facilities judge their compressed air systems.

While anyone interested should consult the NFPA 99 regulations themselves, here are some key points to keep in mind when considering medical or dental compressed air.

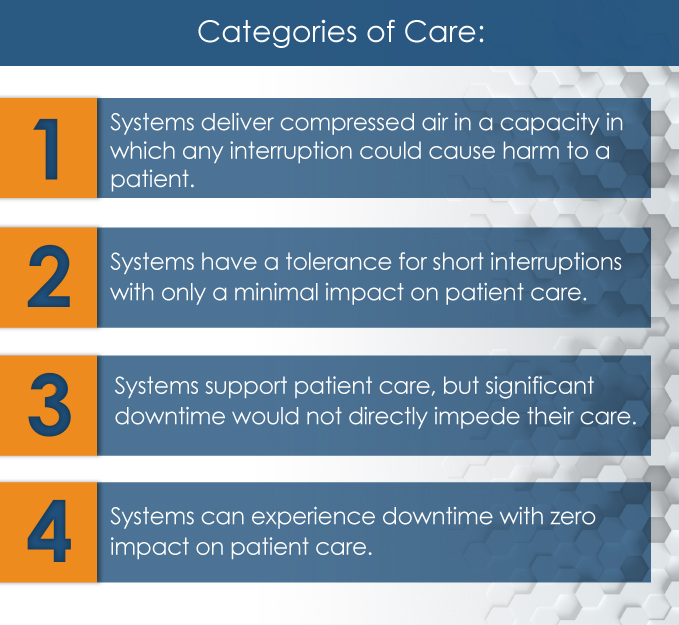

Categories of Care

Recently updated NFPA 99 regulations now break down medical compressed air systems into four categories:

- Category 1 systems deliver compressed air in a capacity in which any interruption could cause harm to a patient, such as life-support systems.

- Category 2 systems have a tolerance for short interruptions with only a minimal impact on patient care.

- Category 3 systems support patient care, but significant downtime would not directly impede their care. Specifically, loss of these systems may cause discomfort but would not otherwise cause harm to a patient.

- Category 4 systems can experience downtime with zero impact on patient care.

Required Dew Point

As part of current NFPA 99 regulations, the dew point of medical air must be at or below the frost point at every point within the system. That means dryers cannot be installed immediately before the end-point of the system. The regulation also dictates that the dew point be at or below the frost point regardless of how much pressure is being created by the compressed air system. That means dryers have to be able to handle fully lowering the dew point while the system is operating at maximum capacity.

In order to ensure that medical air is maintained at the proper dew point, monitors and dew point alarm systems must be installed at both the end-point and the source.

Further Thoughts on Moisture in Medical Compressed Air

While we are on the subject of things like dew point requirements, it is prudent to further discuss why moisture is a problem within medical air. Doesn’t the atmosphere we breathe every day contain moisture?

In short, moisture in the air when exposed to ambient temperatures will condense, forming droplets of water within the piping of a compressed air system. This water then becomes an ideal breeding ground for microorganisms. While it is true that microorganisms are often present within the very air we breathe, keep in mind that medical air systems provide among other things breathable air to individuals who are immunosuppressed or otherwise extra vulnerable to infection. By delivering 100% dry air, you can best ensure that respiratory systems are bacteria free.

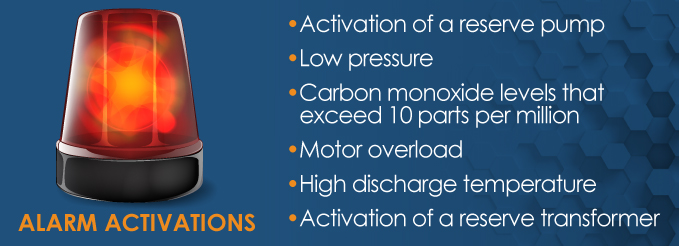

Additional Alarms

In addition to alarms alerting users of high dew points, NFPA 99 regulations require that alarms be activated in a number of other situations. These include:

- Activation of a reserve pump

- Low pressure

- Carbon monoxide levels that exceed 10 parts per million (ppm)

- Motor overload

- High discharge temperature

- Activation of a reserve transformer

It is important to make sure your monitoring equipment meets required code specifications.

Medical Air Source Requirements

According to the most recent update of the NFPA 99 regulations, the intake of the compressed air system is required to be at least 25 feet from any exhaust or vent, 25 feet from the any source or collection of noxious fumes and 10 feet from a window. All piping must also meet grade standards and can be made from copper or steel.

While we hope this quick overview of NFPA 99 regulations will give you an idea of what’s required. If you are looking to implement a medical-grade compressed air system, it is imperative that you investigate further and thoroughly in order to make sure you are in compliance. Many features of the regulations are exacting. While many compressed air systems will be labeled as NFPA 99 compliant, the specific requirements of installation demand strict oversight.

Oil-Less Compressors

In order to consistently provide clean, breathable air, medical compressors are typically oil-less. While most industrial air compressors rely on lubricants to ensure smooth and dependable operation, the risk of air contamination rules out standard lubricants for medical compressed air applications.

Standard oil-less compressors come in two varieties. The first is oil-less reciprocating compressors. While these are very reliable, they have proven to be problematic when required to be in constant use, as the piston system must occasionally cool. Newer oil-less reciprocating compressors address this issue by implementing cooler running piston systems.

Oil-less scroll compressors don’t suffer the same issues with overheating commonly associated with that reciprocating compressors. Scrolls have proven to be reliable even under a 100% duty cycle. Due to the technology implemented in these compressors, the motors are air cooled.

Banking Compressors

Medical compressed air applications tend to vary in end-point demand. That means during peak times, medical facilities require large amounts of compressed air. However, during times of low demand, operating at full capacity can be costly.

To address this issue, many hospitals and medical facilities have opted for “banking” their compressors. Instead of having a single large-capacity compressor, a number of smaller compressors are used. That way, when a large amount of compression is required, all the compressors can be turned on in order to meet demand. However, during times of lower demand, redundant compressors can be shut off as a cost-saving measure.

Air Purification

While it is clear that medical air needs to be pure, what is the best approach for ensuring medical-grade compressed air quality?

Initially, you need to ensure you start with a specially treated compressed air holding tank that won’t be contaminated due to corrosion. These often feature either an epoxy lining or galvanized coating.

You also need to invest in robust filtration to remove any particulate contamination. While regulations are strict about source air, further filtration is essential since particulate contamination is possible at a number of points within a compressed air system.

Most medical air systems use both a particulate filter and a carbon filter. This ensures that no contaminants over 0.01 microns are present in medical air. Additionally, any lubricant vapors or odors will also be removed, further improving the air quality of your compressed air.

In order to make sure purified air isn’t re-contaminated further down the line, all piping must be cleaned and rated for oxygen service.

Finally, make sure you have the strongest dryers available to remove moisture from your compressed air.

While refrigerated type dryers are common, they are not capable of drying air to the required dew point when air is under 100 pounds per square inch (psi) of pressure. If you are using a refrigerated dryer, the pressure of the compressed air must be lowered to 55 psi. While this is possible, many of those who are installing new compressed air systems are instead opting to install a desiccant type dryer.

Desiccant-type dryers use a chemical process in order to absorb moisture. Compressed air is pushed through two towers that contain either a molecular sieve or activated alumina. This allows the dew point to be lowered regardless of the desired system pressure.

Noise Considerations

While ambient noise may not be regulated by NFPA 99 requirements, most facilities implementing medical-grade compressed air also consider how noise may impact patient care.

Because medical facilities often attempt to provide an environment that promotes rest in addition to essential care, medical-grade air compressors are designed to run quietly. While standard industrial compressors can be loud, medical compressors employ noise-reduction measures.

However, for large medical facilities, such as large hospitals, quiet compressors may not be sufficient for meeting compressed air requirements. In these instances, many hospitals opt to locate compressed air systems in places where operational noise won’t disturb patients.

The Importance of Reliability

Of course, one of the most important considerations when selecting a medical-grade air compressor is reliability.

In order to provide Category 1-grade medical air, redundancies must be in place to ensure that air pressure is never lost, since it is life-sustaining. This requires outfitting compressor systems with a generator and providing ensuring back-ups are in place in the event that a main compressor malfunctions.

However, while redundancies are both essential and required, the best compressed air systems will never actually require that every redundancy be activated. That’s why it’s so important that medical and dental facilities invest in the highest quality compressors available on the market.

The Importance of Precision

Finally, when implementing medical-grade compressed air, it is equally important that the system can be controlled precisely.

For example, when delivering compressed air for medical respiration assistance, it is imperative that the pressure of the compressed air be tightly regulated. Not enough could cause the breathing apparatus to fail to deliver the required levels of oxygen. Too much could lead to potential patient injury.

When choosing a compressed air system for medical and dental applications, make sure to invest in a system with a high level of control.

Rely on Quincy Compressor for Medical- and Dental-Grade Compressed Air System Support

Now that we’ve discussed the various requirements and considerations for delivering medical-grade compressed air, where should you turn to either purchase new equipment or get pre-existing equipment serviced?

For nearly a century, Quincy Compressor has provided the highest quality compressed air equipment to a wide range of industries. While our compressors are trusted in machine shops and wood-working facilities, our reputation for reliability and precision also means we are equally well-suited for medical facilities.

We also offer many of the essential accessories that are designed to ensure your compressed air meets the exacting requirements for air quality present within medical facilities. If you are looking for dryers, we offer desiccant dryers that are designed to lower dew points below the 32-degree threshold required.

If you are looking for the most robust filtering technology available on the compressed air market, look no further than Quincy Compressor. Our wide range of air-treatment equipment has set the industry standard for air quality, which is exactly the kind of approach any medical professional looking to employ compressed air needs.

As with any of our air compressor technologies, our commitment to quality construction extends to include an equal commitment to service and support. Whether you are looking to improve the reliability of your current compressed air system or you are trying to find ways to improve energy efficiency, our award-winning Efficiency Quotient program is a great way to explore cutting energy costs while improving overall performance.

Whether you are looking to purchase and install a new system or schedule maintenance for an existing one, our sales and service locator is a great way to find one of our certified and excellent sales representatives. While many companies are increasingly conducting their business on the internet, we understand that with a purchase as significant as a new compressed air system, sometimes the best way to be confident is to work with a real person. That’s why we want to connect you with someone who is well-versed in the intricacies of choice Quincy Compressor equipment and compressor accessories.

So contact us today! Our professional and courteous sales and support staff look forward to hearing from you. And everyone here at Quincy Compressor is excited to meet new partners. We are tireless in our efforts to support the many industries that use compressed air to power their processes. You can count on Quincy Compressor to provide you with the power you need to serve your patients and keep your industries, hospitals and businesses running.