Quincy Compressor is a longstanding global leader in air compressor technology, with a history dating back to

1920. Over nearly a century in business, we’ve established a reputation for continued innovation, as well as providing highly reliable products.

Industrial and commercial users can count on Quincy air compressors for years — if not decades — of dependable service. Whatever your application, there’s a Quincy air compressor that will get the job done with minimal maintenance requirements and a low cost of ownership.

Our Versatile and Dependable Air Compressors

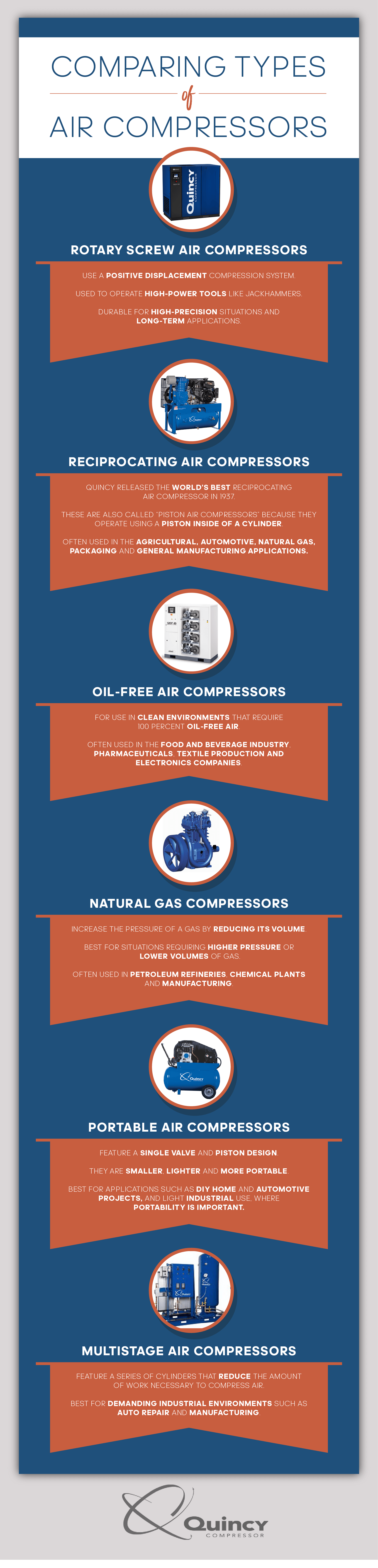

Quincy manufactures one of the most diverse lines of air compressors on the market today. Our types of air compressors include:

Rotary screw compressors: Quincy rotary screw air compressors range in size from 5 to 350 horsepower, and can deliver up to 1,500 ACFM of pressurized air. From the belt-driven QGS product line to the direct-drive QSI, we manufacture options for all customers.

Reciprocating air compressors: Quincy released the world’s first reciprocating air compressor, the QR-25, in 1937. Today, the QR-25 remains the industry standard in pressure-lubricated air compressors. Several other models, including the QP and QT series, complement it in our current lineup of products.

Oil-free air compressors: We design our oil-free air compressors for use in clean environments where minimizing the risk of contamination is essential. The QOF line of products meets ISO 8573-1, Class 0 requirements for air purity while delivering efficient performance in any task.

Natural gas compressors: A variety of industrial facilities, including petroleum refineries, chemical processing plants and manufacturing operations, use natural gas compressors instead of electric or diesel-powered units. We offer several models, including the QSG rotary screw compressor and QRNG reciprocating compressor, for these and other applications.

Portable air compressors: Quincy portable air compressors are ideal for home and light industrial use. Whether you’re powering air tools, inflating a tire or airbrushing a car, our portable products deliver all the power and performance you expect from a Quincy compressor, in a compact package that’s ideal for DIY use.

Multistage air compressors: Multistage compressors are capable of delivering pressure and airflow levels beyond that of a single-stage unit. As a result, they are the ideal choice for demanding industrial environments that require running multiple tools at once, or tasks necessitating extremely high pressures. Many of our most popular products, including the QR-25, are available in two- and three-stage configurations.

In addition to our air compressors, we also manufacture and sell a full selection of replacement parts and accessories, as well as desiccant dryers, vacuum pumps, air treatment systems and more.

Buy Industrial Air Compressors with Confidence

When you buy an air compressor from Quincy Compressor, you are buying a product backed by decades of research and some of the best warranty coverage in the industry. Visit our individual product pages to view detailed specifications and other product information, or find a dealer in your area for assistance today.

Different types of air compressors can be found in major industrial settings that process our food, jet engines that get us where we want to be and even that supercharger under your hood.

All of these applications have led to a wide range of air compressor types and components. Choices aren’t as simple as reciprocating air compressors versus rotary screw type compressors, however. Instead, you’ll have pressure, maintenance, equipment, locating, housing and many more considerations. Thankfully, the specialized nature of many compressors means an air compressor types comparison is becoming easier, and so is the selection process.

Whether you’re looking for a compressor for your home workshop and basement, a construction site or an industrial setting, many of the questions are the same. So, let’s start with this big guide of air compressor types comparisons to answer the question of: What type of air compressor do I need?

Positive vs. Negative Displacement

Just about every compressor falls into one of two categories: positive or negative displacement compressors. You’ll more likely see a negative displacement compressor listed as a “non-positive displacement” compressor because that’s technically a more accurate description of the system.

Displacement type sorts the two categories based on how pressure energy is delivered and imparted into the air itself.

Positive Displacement

For positive displacement compressors, air is usually trapped between two moving components and then forced to occupy space of a lower volume, increasing its pressure. Air can be caught and trapped between parts such as pistons and cylinders where it is then stacked and pressed downward to increase pressure.

Positive displacement air compressor types are the most common types of air compressors. You’ll find them in home use, hobbyist applications, small worksites and even in industrial applications. Some of the most common positive models are piston compressors.

Positive displacement can also use rotary screw compression to create air chambers and allow rotation to compress the air in a given space. Most of these compressors will use oil as a lubricant at the motor’s compression point, and they tend to feature a solid seal. In these cases, they include a system that removes the oil from the compressed air in order to avoid contamination.

Non-Positive (Negative) Displacement

Kinetic energy from rotating components is used to create pressure in non-positive displacement compressors. There’s often a lot of rotation in air compressor types and components that use non-positive displacement. This can include centrifugal compressors, rotating impellers and more.

Essentially, these compressors operate without creating the true physical displacement that positive compressors need.

Non-positive displacement types of air compressors often have a fluctuating pressure based on the speed of the rotating element, such as an impeller, so they are often used in low-pressure deployments.

Reciprocating and Piston Compressors: Single-Stage and Two-Stage

One type of positive displacement compressor is the reciprocating air compressor, though you may also see it called the piston air compressor. These air compressor types rely on a piston inside of a cylinder for their operation.

As the compressor operates, the piston moves down, and air fills the upper portion of the cylinder — based on the difference in atmospheric pressure and the pressure of the cylinder. Compression of the air occurs when the cylinder moves upward. Standard units are single-stage because they typically contain a single piston and cylinder.

Two-stage reciprocating air compressors will have two pistons, each in their own cylinder. These are often set at a 90-degree angle and can look very similar to the pistons that stick out of a V-8 engine. A two-stage piston compressor operates in a similar way to the single-stage compressor. The air intake method is the same, but it adds another step for compression so it can maximize the strength of the two cylinders.

During the first stage, the air is compressed to an interim pressure amount, but this generates some heat. After the piston moves again, the heat is removed from the compressed air, and then it is transferred to another cylinder. The second cylinder is set to a pressure amount, and it repeats the downward-upward motion to compress the air to that set pressure value.

Rotary Scroll

Rotation is a top method for compressing air across multiple types of air compressors. First on our list of rotary compressor types is the rotary scroll compressor.

This unit is designed with longevity in mind because its rotation involves only a few moving parts — a significant departure from some air compressors such as the rotary screw compressor.

A single helical element is set at the center of this compressor. It’s fixed so it can continue to spin (or orbit). This will slowly compress the air inside of its housing as well as slowly draw in more air from a specific source or the general environment.

These compressors will often sound a little different and work a little smoother than other air compressor types, even if their maximum power levels out sooner. This occurs because of the gradual pressurization and intake processes. The system doesn’t pulsate due to motor changes, so it delivers a continual supply of air.

Rotary scroll air compressors have different intensity levels, so they may require lubrication for larger systems or when producing greater pressure. However, many common rotary scroll models feature an oil-free design.

Rotary scroll compressors are often used to compress air and coolants. They’re smooth and reliable because the orbits are easy to counterbalance, reducing vibrations. This makes them optimal for inclusion in small situations and when working in conjunction with a lot of moving parts.

The technology plays a role in many air conditioners, vacuum pumps and even in some superchargers for vehicles. Volkswagen’s G-Lader is a specialized scroll compressor that’s used in the carmaker’s passenger car models.

Rotary scroll air compressors use fewer moving parts than other compressors on our list, and that makes them more reliable in many situations. However, it’s always best to look for the latest research on reliability because scroll compressors are very vulnerable in situations where debris can enter the system.

Rotary Screw Type Air Compressor

Rotary screw compressors make use of two mated helical screws housed in a central container unit. These screws are powered so they rotate briskly, increasing the air pressure inside of the chamber. When the air pressure increases, the overall volume of air is decreased, compressing the air and providing some increased capability for the system.

You may not run into a rotary screw compressor all that often because the internal mechanism generates a significant amount of friction. Rotary screw type air compressors require a coolant and lubrication, increasing cost and decreasing long-term efficiency of the system (because there is more maintenance and checks required).

Rotary screw compressors do tend to have lower leakage levels compared to other models, especially when used in superchargers. This allows them to operate in high-precision environments as well as long-term rugged use situations.

Oil is often the lubrication of choice for rotary screw air compressors, but that causes more work for the compression system itself. Before any compressed air from this type of compressor can be used, there needs to be a mechanism in place that separates the oil from the compressed air.

Rotary screw type air compressors are able to deliver high-pressure as needed, making them the compressor of choice for big impact equipment like a jackhammer. Diesel-powered units are common at construction sites all across the U.S. because of their flexibility and reliability. If there’s a compressor pulled behind like a trailer, it’s probably a rotary screw type of compressor.

However, models that operate oil-free are also used in other, more delicate situations. Large, oil-free rotary screw type air compressors can have a significant output and keep it up well, so they’re a go-to for medical research applications and precision manufacturing, such as the creation of semiconductors. The layout of these compressors make them easy to use in conjunction with equipment that removes unwanted debris or elements, such as hydrocarbons, from the ambient air.

Rotary Sliding Vane

The rotary sliding vane is a fancy name for a fancy-looking air compressor type that’s been around for a long time. This model will use a significant motor that houses a rotor, stator and a series of blades that rotate. The Italian engineer Agostino Ramelli actually described the motor’s mechanism all the way back in 1588, and the “modern” design we use was patented by Canadian engineer Charles C. Barnes in 1876.

Air compressors using the rotary sliding vane motor are common in automotive and hydraulic applications, such as the power steering in many cars as well as some vacuums.

The blades, also called vanes, are set inside of the central spinning rotor, and they move out and in as space allows. The rotor is set off-center so one side nearly touches the end of its casing, which forces the vanes to move in as they approach this tight space. As the rotor turns, the vanes slide out (thanks to centrifugal force) until they touch the casing. Air is caught between the vanes, and the volume of the air is reduced as the rotor turns, raising the air’s pressure.

Motion is relatively steady and pressure continuous, so these compressors work well for medium-pressure situations. Unfortunately for the rotary sliding vane compressor, many newer models are able to perform low-pressure and high-pressure tasks more efficiently. This is why you’ll still see vane compressors in automotive uses but will struggle to find them in modern vacuums.

If your needs are of a higher pressure, say above 80 psi, then you’ll likely have better performance and cost savings by using a rotary screw air compressor. General costs and maintenance are about the same, but rotary screw compressors can perform better at stronger pressures and will take less wear as you move even higher.

In vacuums and other lower-pressure situations, many companies are now turning to claw pumps for improved efficiency. The claw pump will cost a little more at purchase, but they deliver the same pressure at a lower power consumption and typically have less maintenance needs than a rotary sliding vane compressor.

Rocking Piston Air Compressors

Sometimes you need a small air compressor that operates at a lower pressure and doesn’t require a splash lubrication system to operate. In these cases, you may want to consider a rocking piston air compressor. These units are quiet and compact, making them a top choice when portability is demanded.

The rocking piston compressor takes standard pistons from your one- and two-stage compressors and then adjusts them slightly out of the standard piston deployment. For air compressors, after air enters the chamber, it is pressurized as a connecting rod and piston interact. Heavy-duty units will have metallic rings and internal parts, but many of these also use non-metal pieces that don’t require any lubricant.

Rocking piston air compressors are commonly used for tasks like aerating small ponds as well as other deep water applications. They’re able to operate 24/7 for these types of low-load jobs. Parts and maintenance are relatively inexpensive and easy, which furthers their appeal for home and business aeration services.

Centrifugal Air Compressors

The first on our list to not use positive displacement is the centrifugal air compressor. This type of air compressor relies on the principle of dynamic compression, which increases air pressure by raising the velocity of the air.

Centrifugal air compressors rely on a central impeller to operate. Impellers are made from materials like iron, steel or bronze — stronger materials for greater pressures, though some small units will have plastic impellers. They operate by spinning up to 60,000 times per minute. It transfers energy from its motor to the air by driving the air outward across its casing.

The powered air is then slowed down through intercoolers and diffusers, cooling the air and removing fluid that may build up in the process as the air is pressurized. The systems often have outlets for liquid because moisture in the internal workings can cause damage.

Mesh impellers are common in centrifugal air compressors like the one in the Roots Blower, which is used in some car engine superchargers, and help move air through systems. Diesel engines in large transportation vehicles will often feature these superchargers. On the large, industrial side of things, you’ll find centrifugal air compressors in big ventilation systems, blast furnaces and industrial-strength combustion engines.

Centrifugal compressors are also very common when companies are looking to compress gas in oil platforms as well as for liquid natural gas (LNG) and liquid petroleum gas (LPG). When using LNG and LPG platforms that require storage or have transport installations, smaller centrifugal compressors are often on hand.

Constant load requirements and capabilities are the hallmark of centrifugal compressors. The consistent operation of the inducer, impeller and diffuser is best for the system. The design also allows you to consistently activate it while scaling overall use up and down as needed.

When compressed air is in less demand or when the pressure requirement is lower, the impeller can reduce its speed. This reduction actually allows the overall centrifugal compressor to increase its capacity, giving you long-term security and preventing mechanical concerns.

Efficiency is the major choice for this when working with a clean intake and consistent use. You’ll find centrifugal compressors in single-stage, two-stage and three-stage models, making them potentially more efficient than some screw compressors (and many other positive displacement compressors).

Rotary Lobe Air Compressor Types

Many of the compressors we look at today have a storied past, and that includes the rotary lobe pump — which have been working in industrial situations since their 1860 invention by the Roots Brothers. Originally designed as a water motor for a mill, they discovered the machine was powerful enough to assist workers smelting iron.

Rotary Lobe compressors have been in use ever since, and they’re often called Roots Blowers after the Roots Blower Company the brothers founded to initially sell them. Some of the most common uses today are for pneumatic conveyance, which is in just about every industrial mill for flours, grains and rice.

Rotary lobe air compressors are also positive displacement pumps, but they operate a little differently than the others on our list. For starters, the volume reduction that creates air compression happens outside of the pump itself.

The pump contains two rotors with two or three lobes a piece. Think of the infinity symbol for rotors with two lobes. One rotor is connected to the engine and rotates under that power. As it spins, it pushes on the second rotor and spins it in the opposite direction. These rotors need to fit together like puzzle pieces, so rotors must be precision machined, and the compressor can be put at risk if there’s debris or damage.

As the two rotors spin, air is sucked in via the inlet and pushed out, so the volume reduction occurs at this point of discharge. Air is pushed down a pipe, and more-and-more air is stacked in the pipe to increase overall air pressure. This typically creates low pressure air at high volumes.

Rotary lobe air compressors produce high volumes of air, require very little maintenance and are designed to fit in most industrial applications interchangeably. They also can take a beating as long as you keep the intake clear. That means you’ll find them in consistent-use situations in nearly any type of industrial setting.

The downside for the rotary lobe compressor is that they top out at about 15 psi, so you’re not going to see major pressurized settings. These compressors also have a consistent amount of slip — air that escapes from the system as the rotors spin — so they’re not the most efficient. If you need a quiet compressor, you’ll also have to install a silencing box around it because these tend to be very loud.

However, for rough situations where you need large volumes of air at a decent amount of pressure, you might have found what you need in the rotary lobe compressor.

Axial Flow Air Compressors

Modern jet engines use what’s known as the axial flow compressor in their operation. This air compressor type increases the pressure of air before it’s injected into the burner, and the better the compressor performs, the better the engine performs.

Axial compressors come in multiple stages and often look like what we think of when we think of a turbine. The compressor rotates, and air flows through the series of rotors, parallel to the axis of rotation. A central shaft spins, spinning typically half of the rotors in concert, while “stators” serve as fixed rows of airfoils in between the rotors.

Stators help the axial compressor keep the air flowing and properly pressurized. Without them, air would start to spiral around the axis and disrupt the flow, creating wasted energy and lowering the pressure. This helps to improve the success of these compressors.

Early models in the 1920s were poor and made the probability of jet engine flight look impossible. By introducing stators and airfoils instead of flat blades, however, these compressors were actually able to make flight look feasible. They played a pivotal role in the early jets of the 1930s and 1940s, and by the 1950s, every major jet engine was using an axial flow design.

Axial flow air compressors are able to deliver significant pressure continuously. That makes them a top choice for jet engines, electric motors, steam turbines and gas turbines. While not the most common in small industrial or personal settings, they do perform very successfully in the aerospace sector as well as in large-scale operations.

Common uses for axial flow compressors outside of jet engines include high-speed ship engines, small power stations, air separation plants, large blast furnaces, propane dehydrogenation operations and catalytic cracking air services.

Axial flow air compressors of significant size often require testing in a wind tunnel, which can make them a significant investment.

Other Sorting and Selection Considerations

When you’re asking yourself “What type of air compressor do I need?” remember that there are other things to consider beyond just the overall type. Sometimes your needs will include restrictions on lubrication methods, prime movers, stages or cooling methods.

Here are a few essential things to consider during your selection for the right air compressor:

Prime Movers

Most air compressor deployments can take their pick from prime movers, ranging from electric motors and diesel engines to larger turbines that feature clutches and reduction gearing. Turbine-driven air compressors are relatively rare because of their complexity, but they can be a strong choice when you have the space and want a minimal fuel or heat generation added to your overall industrial system.

Electric motors tend to be the most common prime movers because they’re able to start and stop efficiently, especially in automated processes. They also perform well in unloading and loading sequences. Diesel engines tend to operate in logistics and transport situations, especially for turbochargers, because they can use existing systems. They are also a bit more rugged and work well in situations where you need to bring an engine and compressor around a worksite.

Stages

Stages tend to correlate to the overall pressure of the system you need. For situations where delivery pressure is low but stable, you’ll likely be able to use a single-stage air compressor. When the pressure requirement starts to push above 10 bar, the stress and requirements will outstrip what a single-stage system can do.

Two-stage air compressors may be your air compressor type of choice when you need to up the delivery pressure. Whether you’re able to fit a reciprocating compressor or pack in a rotary centrifugal version, stages push up capabilities. Three-stage compressors are pretty rare, but they’ll come with an increase in pressure capabilities as well as an increase in spatial needs.

Drives

Air compressors tend to fall into one of three categories based on their drive: direct, gear-driven and belt drives.

Direct drive compressors tend to be small, single-stage compressors for light commercial and home uses. They often feature electric motors as well. They’re small and need very little maintenance, which also means they tend to not need any oil.

Direct drive compressors are either directly coupled to the power source or are flange-mounted to it, improving performance. The orientation often is picked in order to give it best access to air in the atmosphere. This allows direct drive compressors to start the compression process without any pre-filling of an air tank.

Gear-driven drives don’t face the same alignment concerns and maintenance needs of most direct drives, making them preferable for high-horsepower needs. The compressor speed can be adjusted to be different from the motor speed, providing flexibility for its use.

One important note is that a gear drive always requires a close eye on lubrication to avoid damage due to its high operating speed. Gear-driven setups are roughly a middle-of-the-road on maintenance, requiring slightly less care than direct drives, but more frequent inspections than the 500 hours that a belt driven can go between inspection and tension adjustment.

Belt driven compressors are found on both electric and gas deployments because they’re much more customizable. Large oil-lubricated air compressors tend to be belt driven because there are multiple layouts and features that improve overall performance and pressure outputs.

We recommend belt drive compressors when you have very specific needs for compressor loads relative to the power source, but you still want a lower price. They also tend to be quieter since they require oil. Overall, belt driven compressors tend to have lower maintenance costs and are less likely to break down.

Belts will require more maintenance and always need a protective casing, but they tend to be the powerhouse of the drive types.

Coolants

Air compressors use three main systems to keep everything protected and cool: water, oil and ambient/atmospheric air. The choice often depends on other equipment in sequence and the size of the compressor.

Small types of air compressors often use ambient air in the atmosphere to act as their cooling agent. Air, especially when it moves, is a good conductor of heat. Small systems typically generate smaller amounts of heat, so air can whisk away excess heat from the cylinders. They’re often able to achieve near-isothermal conditions just by established motions of the compressors themselves.

As stages grow, an increase in heat accompanies the increase in pressure. For almost all two-stage air compressors, ambient air is not enough to keep things cool — sometimes this is based on overall heat, and sometimes it is just the size compressors reach to accommodate multiple stages. Water cooling is a common method to keep most two-stage compressors cool.

Water cooling is performed by forcibly injecting water around the cylinder walls to absorb the heat. Water is also a smart heat conductor. Moving it to the cylinder where it grabs heat as it flows past (or even becomes a vapor) then on to a cooler section allows the water to transfer the heat and condense again. Systems often rely on gravity and general pressure to keep water flowing, heating and cooling. These systems typically don’t require any extra energy and are able to put up with vibration and use, making them suitable for many building installations.

In special cases where the system doesn’t have enough room or where nearby heat sources could cause vaporization of water away from the cylinder, oil is used. Cooling oil transfers heat in much the same way as water, but temperatures won’t rise high enough to vaporize it. That means it will require an additional power source for a built-in sump pump. While a little more expensive and less common, oil coolant systems provide significant heat transfer and are extremely durable.

Lubrication

Separate from the cooling system, some air compressors will need a lubrication system to keep internal parts working appropriately. Excess heat can not only damage the metal parts, but excess friction can also introduce extra elements to the compressed air. Metal flakes and other particles can cause significant damage if they’re passed to pressurized air tanks and injected into other machinery.

For the lubrication purpose in compressors like a rotary screw compressor, a splash technique is often used. This applies the lubricant by having a gearbox essentially sling the lubricant onto a trough above the system. Existing motion can power this, and then the lubricant steadily drops onto the parts that need it.

Splash lubrication systems are pretty simple and inexpensive, but they’re not able to deal with larger sized air compressors or those with parts that are moving very rapidly. When speed and size increase, force-feed lubrication is often employed.

The force-feed system is actually powered by an oil pump driven by the compressor, which is a nice feature that can save you some space. Lubrication oil is sucked through tubing and is steadily applied to the compressor parts that need it. Lubrication is not only constant, but it is applied at such a rapid pace that it requires a significant reserve and filtering process.

Specialized air compressors are again the exception to the rule because they don’t often need any type of oil for lubrication. They’ll use other mediums or forgo lubrication completely by reducing their workload to keep parts from stressing under heat.

Piping Systems

Compressed air systems rely on piping to make proper use of their power. Pipe selection, layout, installation and maintenance can all play a role in how powerful the system remains and if you’re losing energy along the way.

Look for piping systems that work with your compressor type and allow for installation that avoids sharp angles, moisture, obstructions and blockages. All of these issues can harm performance and cause your air compressor to work harder to deliver the same load.

Piping can be a complex layout equation, so consult this guide to ensure you have the right design for your industry and shop floor.

Your Checklist for Purchasing an Air Compressor

The final consideration for your compressor choice is the checklist you need for choosing the right compressor. Here are just a few of the questions you’ll want answered and set in front of you when it comes down to purchasing:

- Where will you be using your air compressor? Does the site have a fixed location or will you need something stable and secure enough that you can move it around your work area with ease?

- Do you have easy access to a stable electrical supply? Electric models are a little more reliable because gas generators can cause power fluctuations, but electric models tend to be more fixed units.

- What tools are you going to use with your compressor? What CFM requirements do they have?

- What’s your most important metric: Air generation? Air storage? Workload? Technology support?

- What are the standard and maximum operating pressures you’ll require?

- What’s the maximum air volume you require?

For further explanation of these questions that might help you answer them better, please see this Quincy Compressor guide to narrowing down your compressor choice.

Learn More From Quincy Compressor

Determining which is the right air compressor type for you can be a little complex. It all comes down to your specific usage needs, any custom requirements you have and what existing machinery you want to use with your new compressor.

All of those options change what types of air compressors are available to you and which is the best purchase. Quincy Compressor provides as many resources as we can to help you learn how to size and select an air compressor.

Contact our knowledgeable experts near you to learn more about what options are available in your area, what the true cost of ownership is and much more. The goal of Quincy Compressor is to help you pick the right type of air compressor that keeps your operations running smoothly.

Visit our sales and service locator to find a dealer near you!

Table of Contents

- Versatile and Dependable Air Compressors

- Buy Industrial Air Compressors with Confidence

- Positive vs. Negative Displacement

- Reciprocating & Piston Compressors

- Rotary Scroll

- Rotary Screw Type Air Compressor

- Rotary Sliding Vane

- Rocking Piston Air Compressors

- Centrifugal Air Compressors

- Rotary Lobe Air Compressor Types

- Axial Flow Air Compressors

- Other Sorting and Selection Considerations