Compressed air is used in many different industries. From refrigerator manufacturers to toy makers, companies around the world depend on compressed air to produce products. It’s so important that many consider it a utility as significant as electricity, water or natural gas.

Unfortunately, compressed air is also an expensive utility to produce. Many businesses spend tens of thousands of dollars generating compressed air. And lots of this air goes unused. In fact, we found nearly half of all compressed air is wasted.

As experts in the industry, we understand the true cost of compressed air. Additionally, through decades of experience, we know potential savings can be tremendous with an energy-efficient compressed air system. Below, you’ll learn what impacts the cost of compressed air, how to calculate these costs and how to cut them back.

Contact Us Learn More Find a Dealer Near You

Types of Air Compressors

One factor that determines the price of a compressed air system is the type or model of air compressor that is used. Air compressor value can change based on the system’s size, configuration and application. Knowing the various types of compressors and how they work is essential to understanding why certain models cost more than others. Popular types of compressed air systems include:

- Rotary screw compressors: Rotary screw compressors are the most popular type of air compressors — especially for heavy duty applications. These compressors have a large screw that forces air into a cylinder as it turns. Once in the cylinder, the air is compressed.

- Reciprocating or piston compressors: Another popular type of compressed air system is the reciprocating or piston compressor. This compressor uses a series of cylinder and valve mechanisms to achieve the same result. Most reciprocating air compressors cost less than comparable rotary screw models, particularly for light- and medium-duty applications.

- Oil-free compressors: Most air compressors are lubricated to reduce wear. However, oil-free compressors are also available for use in sensitive environments where managing potential sources of contamination is a key concern.

Understanding Compressed Air System Ratings

The cost of an air compressor is directly related to the amount of work it can perform and the efficiency with which it can perform it. This is expressed in several different numbers, including:

- Pressure: Compressors are designed to produce air at a given pressure level. Pressure is expressed in pounds per square inch grade (PSIG). Most pneumatic tools require 90 PSIG to function properly, but depending on the operation, more or less pressure may be required.

- Capacity: Capacity is the rate at which a compressor can produce air at a given pressure level. Greater capacity means you can run more tools or other devices at once. Capacity is expressed in cubic feet per minute (CFM).

- Horsepower: Either an electric or gas motor drives compressors. The power of this motor is measured in horsepower (HP). An efficient motor should produce around 4 CFM at 100 PSIG for every HP. Less efficient air compressors cost more to run but often have a lower purchase price.

- Tank size: Most compressors have a storage tank for holding compressed air, which is measured in gallons. Larger storage tanks add to the cost of an air compressor but increase the amount of time required between compression cycles, saving you on fuel and reducing wear on sensitive components.

The Cost of Compressed Air

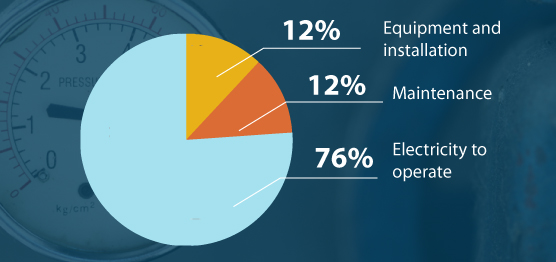

While many people assume the initial purchase of a compressed air system is the largest part of the cost, it’s actually the electricity needed to run the machine and equipment that proves to be the most expensive. In fact, the system itself only costs around 10% of the total cost of producing compressed air.

Air Compressor Costs

Equipment and installation: 12%

Maintenance: 12%

Electricity to operate: 76%

Another important factor to consider when determining the cost of compressed air is warranty coverage. Extended warranty coverage on an air compressor will cost more upfront. However, this investment can provide peace of mind and other benefits in the long term.

Equipment and Installation

Purchasing an air compressor is one of the biggest upfront costs. The price of an air compressor can vary depending on whether you’re looking for a rotary screw compressor or a reciprocating/piston compressor. How you dry and purify air can also affect the price of an air compressor.

Along with equipment, consider the cost of installation. If your building needs retrofitting to accommodate the new compressor, factor this in.

If you’re purchasing a new air compressor, you should include any rebates in the price. Many Quincy Compressors are eligible for energy efficiency rebates, which can bring down the cost of equipment.

Maintenance

Around 12% of a compressed air system’s lifetime cost comes from maintenance and repairs, according to Energy Star data. These expenses include labor and replacement materials. You may also have costs from project delays if repairs are needed at a critical time.

Regular inspections and maintenance can decrease repairs. Set up an inspection schedule, and stick to it. It’s much easier to prevent damage than it is to repair it. In addition, you’ll be able to find and make repairs when the damage is minor. This can help you avoid more expensive and time-consuming damage down the road.

Some parts of a compressor are more susceptible to damage than others. Common problems include air leaks and damaged cylinders, rings and bearings.

Components that are likely to develop leaks include:

- Open condensate traps and shut-off valves

- Fittings, couplings, tubes and hoses

- Pressure regulators

- Joints on pipes, thread sealants and disconnects

You can lower the risk of damaged rings, bearings and cylinders by regularly lubricating your equipment. Choose a suitable oil to lubricate air lines, bearings and screws. Keeping lubricant clean, applying the correct amount, and regularly lubricating components can prevent many repairs.

Electricity

Believe it or not, operating a compressor is usually more expensive than purchasing one. Energy Star says, on average, 76 percent of the lifetime cost of an air compressor is electricity. In many businesses, compressed air is one of the most expensive utilities. Over 10 years of operating, a typical industrial air compressor can accumulate up to $800,000 in electricity costs.

Many factors impact the cost of compressed air. How long you run your air compressor and the cost of electricity in your area can both drive up costs. Technical specifications can also affect the cost of electricity. Energy-efficient air compressors cost less to operate than conventional compressors.

Because the cost of compressed air can be significant, Quincy Compressors offers a free walkthrough to establish a baseline of efficiency, otherwise known as EQ. The EQ rating can help you determine what the cost of operating a compressor will be.

How to Calculate Your Compressed Air Costs

Although our EQ rating can help you understand the efficiency of your system, the true cost depends on your use. Determining this cost can help you to reduce expenses. You can calculate the cost of operating an air compressor yourself in just four short steps.

This example uses a small home air compressor, running for just a few hours a day. Plants with industrial air compressors will have significantly higher costs. However, large plants can still use this method to calculate their electricity costs.

1. Determine How Long the Compressor Is On

Throughout the day, most air compressors tend to cycle on and off. While the compressor is cycling on, it draws power. Use a clock or a stopwatch to figure out how long the compressor runs each day. For many businesses, an air compressors use differs by day. You can get a more precise estimate by averaging the compressor’s use over a week. To do this, track your usage for seven days and divide the sum by seven.

2. Calculate How Much Power the Compressor Consumes

Your air compressor should have a wattage rating stamped on its nameplate. Multiply this wattage by the type of current needed to operate it. Many smaller compressors operate on a standard household current, which is 110 volts. Larger air compressors may need 220-volt current.

Example: 15 amp air compressor X 110 volts = 1,650 watts per hour

3. Find the Total Kilowatt Hours Used

You will need to know how many kilowatt hours the compressor uses to determine the energy cost. To find kilowatt hours, multiply the watts per hour by the total amount of time the compressor runs for. Then divide this number by 1,000.

Example: 1,650 watts per hour X 3 hours = 4,950 watt hours

4,950 / 1000 = 4.95 kilowatt hours

So a 15-amp air compressor that runs for three hours will use 4.95 kilowatt hours of electricity.

4. Multiply the Kilowatt Hours Used by the Cost of Electricity

Most utilities charge by the kilowatt hour. This means that you will need to multiply the total kilowatt hours used by the electricity rate per kilowatt hours. If your utility company uses tiered rates, you may want to use the average rate. This will give you a more accurate estimate than selecting the lowest rate.

Example: 4.95 kilowatt hours X 15 cents per kilowatt hour = 74 cents for 3 hours of use

Energy Saving Opportunities for Air Compressors

Luckily, there are many ways to reduce the costs of compressed air. Choosing the right air compressor can reduce your costs by approximately 45 percent. Today there are many energy-efficient compressors on the market.

Quincy Compressor uses an Efficiency Quotient (EQ) rating to set a baseline of efficiency. This will help us recommend the best improvements.

| EQ Rating | 50hp System | 100hp System | 500hp System |

| 85% | $4,973 | $9,944 | $49,722 |

| 75% | $7,458 | $14,917 | $74,584 |

| 75% | $7,458 | $14,917 | $74,584 |

| 65% | $11,187 | $22,375 | $111,875 |

You can also reduce the costs of compressed air by using your compressor more efficiently. Many people run their compressor for longer than necessary. They might also use more pressure than needed or use it for unnecessary projects. Changing when and how you use your compressor can save energy.

Here are specific techniques you can use to save energy on compressed air.

1. Purchase an Energy-Efficient Air Compressor

Many modern air compressors offer better controls and storage than previous generations. If you’re in the market for a new compressor, look for energy-efficient flow control and storage systems.

Flow Control: Nearly half of compressed air is wasted. Flow control tools that can sense downstream pressure and react to small changes can reduce compressed air waste. An example of this type of flow control is the Quincy QGV®️ compressor. The QGV®️ Compressor’s control system senses downstream pressure changes and quickly adjusts.

Storage: Higher storage capacity means a compressor will need to run less often. If you use a lot of compressed air, you may want to consider increasing the storage capacity. In an efficiency study of Mega Brand, we recommended they increase their storage from 400 gallons to 1,560 gallons. That saved them $22,015 a year in compressed air costs.

2. Turn Off Your Air Compressor

Air compressors regularly cycle on and off to maintain the chosen pressure. Even minimal air leaks can cause your compressor to cycle on regularly. Compressors that are constantly running can use a significant amount of electricity. Many businesses leave compressors on during weekends and after hours. If you don’t use your compressor during these times, turn it off. By turning it off when it’s not in use, you can reduce your electric bills by up to 20 percent.

3. Use Only the Required Air Pressure

Although it’s tempting to raise the pressure to compensate for air leaks or clogged filters, you will spend more on electricity if you do so. Each additional 10 sig requires approximately 5% more energy to produce. If you don’t need the additional pressure, don’t use it.

4. Change Filters Regularly

Changing your filter regularly can help reduce the electricity your air compressor uses. Clogged or dirty filters cause an air compressor’s motor to work harder to provide the appropriate psi, which results in a higher electric bill.

Regular filter cleaning can also reduce the cost of maintenance and the likelihood of air leaks. Filters are responsible for removing dust and particles from the air. If these particles get into the compressor pipes, they can quickly corrode the pipes and cause air leaks.

Check compressor pipes regularly for any debris to make sure your filters are performing. If there is dust, dirt or sludge inside of the compressed air pipes, your filters are not doing their job. Replacing these filters immediately will reduce the likelihood of expensive repairs.

5. Regularly Survey for Air Leaks

Regularly surveying for leaks can reduce energy use. This can equate to five to ten thousand dollars a day in big companies. A successful leak audit requires three elements:

- Knowledge: Ensure technicians understand the compressor’s technical specifications and how to inspect the equipment.

- Planning: Plan a regular time to inspect air compressors for leaks. If necessary, break up the inspection so it doesn’t interfere with regular work. Tag and take pictures of any leaks for repair.

- Follow through: Survey equipment again to make sure all tagged leaks have been repaired.

6. Prioritize the Largest Air Leaks

If this is the first time you’ve conducted a leak audit, you may have found many air leaks. This can easily overburden an already-overworked maintenance staff. Prioritize any air leaks you find by size. Larger holes mean your equipment will need more power to maintain air pressure. These should be repaired first. Add a note that includes the priority level of any repairs to be made when you find new leaks.

7. Prevent Large Repairs

Regular maintenance reduces the likelihood of large, time-consuming repairs. It can also prevent smaller air leaks from forming. Check pipes, seals and bearings regularly for corrosion and particulates.

Make sure compressor components are operating within their optimum range. Periodically clean the water jackets and pipes that help to maintain the temperature of the air compressor. If a compressor gets too hot, costly repairs and breakdowns are more likely. If the compressor is air-cooled, check to make sure the fins are not clogged with dirt.

8. Review Piping Infrastructure

You can reduce the amount of energy your compressor needs by optimizing the pipes that deliver air. For instance, you can increase air pressure by reducing the pipe size. This often means you can operate your compressor at a lower psi.

Choosing smaller pipes is one of the most effective ways to increase air pressure. Replacing a 3-inch diameter pipe with a 2-inch diameter pipe will increase air pressure by approximately 50 percent. You may also want to consider whether you can shorten the distance between the compressor and the air end.

9. Reclaim Compressed Air for Heating

Some businesses choose to use the heat from air compressors for heating their building. By recirculating this air, you’ll reduce the need for additional heating.

To make this effective, you’ll need to have ducting installed connecting the compressor to the area you will heat. Reclaiming compressor air for heating is most effective if your compressor is air-cooled. Some businesses do reclaim water from water-cooled compressors for other uses as well.

How to Use Storage to Control Compressed Air Costs

It is possible to inexpensively and safely increase air compressor storage to improve the system’s performance. Without proper storage, air compressors will need to run at higher pressures and require more power. While no one method is a complete solution on its own, there are a few areas and applications where storage should be used to manage compressed air costs, including:

- Storage for speed, thrust or torque

- Storage to protect against pressure fluctuations

- Storage that meters a high flow rate

- General storage to support and create transparency between applications

- Control storage for added support during pressure drops

- High-pressure air storage to reduce peak electrical demand

Remember, when applying storage to a compressed air system, the primary formula requires multiplying the capacity to store by times the allowable pressure drop. Additionally, while engineering or installing storage in a compressed air system, keep in mind the purpose of the system is to deliver the necessary amount of air to the article within the desired time frame.

Overall, basic storage principles can improve the productivity and quality of a compressed air system, which leads to lower operating costs.

Start Saving Money Today

One of the first steps for saving costs on compressed air is to find out where you are currently using the air. After Quincy Compressor conducted its unique Efficiency Quotient program for Mega Brands Inc., Mega was able to reduce the cost of its compressed air by more than half.

Find a Quincy representative in your area today to learn more about how you can reduce the costs of compressed air.