Sustainability and going green are key concerns across many different industries today. Many companies are looking for more ways to green their processes and become more eco-friendly. There are many ways to go green today, and numerous benefits to the environment, human health and a company’s bottom line. Using more environmentally friendly air compressors is one way companies can go green in their production lines, and today’s options are better than ever for the environment. Let’s take a closer look at what makes an air compressor more eco-friendly, how you can make your current air compressors more environmentally friendly and the benefits of greener air compressors.

Evolution of Green Air Compressors

Air compressors have been an essential part in the evolution of many different industrial processes. Everything from manufacturing to auto repair shops makes use of air compressors that power robotic arms, tools and more. Air compressors can power sanders, painters, dryers and other equipment used for jobs that had to be completed by hand in the past. These air-powered tools can complete a job much more quickly and with greater precision as well.

As many industries progressed over the years, companies looked for more ways to save money and increase efficiency in all of their processes. One of the easiest ways to accomplish this is to search for more eco-friendly options, including more efficient and environmentally friendly air compressors.

Today, sustainability is a key issue globally, and it’s no different for manufacturers of air compressors. New models of air compressors are more environmentally friendly than ever. Many of these new models utilize variable speed drives, which increase efficiency and save on energy. Other common factors of more eco-friendly air compressors include being completely oil-free for cleaner production of compressed air and adding electrification for mobile units.

The controls on many of these green air compressors are more sophisticated as well, with updated technology that can constantly optimize production processes. This, in turn, ensures that all other equipment is operating more efficiently and increases the whole system’s overall efficiency. Some systems even monitor faults and failures in the system, alerting workers when maintenance is needed and saving valuable time.

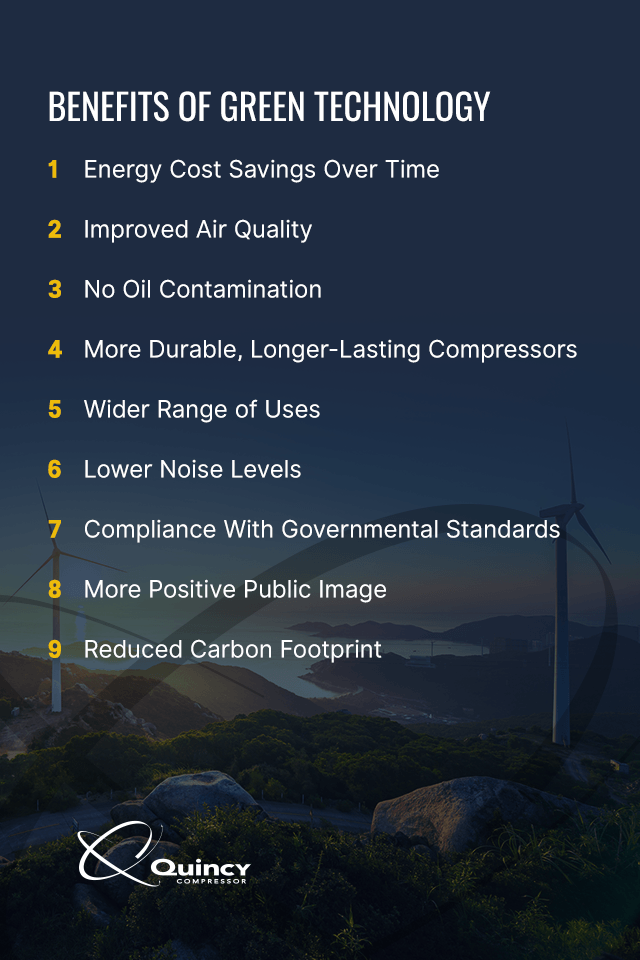

Benefits of Green Technology

The use of more eco-friendly technology like air compressors can have many benefits across many different industries. And the bigger the facility, the bigger the savings and environmental impact, even with just a few simple changes like upgraded, more efficient equipment. Using eco-friendly compressed air solutions contributes to the following benefits:

Energy Cost Savings Over Time

Green technology, like variable speed air compressors, uses less energy to run, which means a facility can save money in the long run with lower energy bills. Larger facilities can save even more on overall energy costs. In addition to the energy cost savings, new variable speed air compressors also have fewer issues with performance and maintenance over time. They can help your entire production line run more efficiently. This means less downtime and less money spent on maintenance too. All of these little savings can really add up, contributing to a lower operating cost for your whole facility.

Improved Air Quality

Many eco-friendly air compressors are oil-free, which means that they operate without any oil at all. These machines do not emit any polluting smoke or other waste gases that could harm the environment and compromise the health of those working in enclosed spaces. Oil-free compressors contribute to cleaner air inside the facility where they are used, as well as the surrounding environment.

No Oil Contamination

Traditional air compressors that use oil are always at risk of oil contamination. When this happens, valuable production time is lost, while labor costs increase to service the machine and production lines. A compressor must be fully serviced when this happens before it can resume production. Oil contamination can ruin products and slow down overall production times. However, with oil-free air compressors, oil contamination is not a concern, and production can keep running smoothly.

More Durable, Longer-Lasting Compressors

Traditional air compressors need frequent servicing, which can slow or shut down production and increase labor costs while the unit is serviced and repaired. A new variable speed air compressor, however, can last much longer, working day after day without needing service and maintenance. In fact, a variable speed compressor lasts on average 100,000 work hours before needing any kind of service. This usually amounts to several years of solid work from these machines before any maintenance is necessary. This also saves in maintenance costs and increases the overall production and efficiency of the facility.

Wider Range of Uses

More eco-friendly options like variable speed air compressors can be suited for a much wider range of purposes. Different tools and machines that use compressed air may require different pressurization demands. Variable speed compressors can handle the different demands of all of the machinery and processes in your facility and can be programmed to do so automatically. Each application of compressed air can have its own precise needs met.

Lower Noise Levels

If your facility already uses gas-powered air compressors, you know they can be quite noisy. This is because these types of compressors need to use an engine to produce compressed air. Most eco-friendly air compressors today use electricity as their power source, avoiding the need for a gas-powered engine. This means these air compressors can run much more quietly, contributing to safer noise levels in the workplace. Many newer models of air compressors also utilize thicker steel or aluminum walls for better sound dampening qualities, as well as sound-dampening enclosures and rubber components to help reduce noise.

Compliance With Governmental Standards

The Energy Policy and Conservation Act (EPCA) from 1975 sets standards for all sorts of products, equipment and machinery, including air compressors. Recently, the EPCA implemented new, more strict, energy standards for air compressors. These new measures were effective as of March 10, 2020, and compliance with the new rules will be required by January 10, 2025. Switching to newer, greener air compressors now means you’ll automatically be in compliance with the new laws and will not have to worry as the 2025 deadline approaches.

More Positive Public Image

Today’s consumers are more aware and concerned about environmental issues, and they are more likely to support companies that put more effort into reducing their environmental impact. Even for companies that do not serve customers directly, public image is very important. Using more eco-friendly air compressors is one of the best choices your company can make to go green. You can advertise your greening efforts, and your public image will absolutely benefit. You’ll enjoy more consumer support and a more positive public image the more eco-friendly changes you make as a company. You can become a leader in your industry and pioneer the future toward more eco-friendly practices.

Reduced Carbon Footprint

Switching to more eco-friendly air compressors can help your company leave a much smaller carbon footprint than you would otherwise. Using variable speed air compressors reduces emissions and decreases energy usage, which helps combat climate change and reduce the impact on the environment.

Strategies to Make Current Air Compressors Environmentally Friendly

If your company already uses air compressors, you can make your existing units more environmentally friendly. To reap all of the benefits from above, follow these tips to make your air compressors more eco-friendly:

Keep up With Maintenance

No matter what type of air compressors your facility utilizes, proper and regular maintenance is key. Traditional air compressors require air and water to operate, and if a unit is not operating efficiently, it can use a disproportionate amount of resources while performing at a lower level of efficiency and output. While you may not be able to completely mitigate these drains on resources and efficiency, especially if you have older air compressors in use, you can reduce the impact with proper maintenance.

To keep your air compressors running as smoothly as possible, ensure that your team performs regular maintenance checks. Ideally, your in-house staff should do checks twice a year, with additional yearly inspections from a trained and experienced repair professional. If you notice any issues during these maintenance checks, take care of them right away.

To further supplement the maintenance efforts, ensure that your employees have time built into their day for daily maintenance activities, like emptying drainage pans. Make sure your staff can complete these daily tasks without rushing through, so they can be taken care of with the proper amount of attention and care. Encourage your staff to report any issues or inconsistencies so you can do repairs before it’s a bigger problem.

Utilize Integrated Pest Control

All sorts of pests, including rodents, snakes and insects, are a common concern in many industrial businesses and can wreak havoc on machinery and equipment in any facility. Many businesses resort to harsh chemicals to keep pests at bay, but this can create a dangerous work environment for employees.

Integrated pest management goes beyond chemical treatments and involves strategic placement and construction of equipment to deter and prevent pest infestations. This includes controlling leaks coming from your air compressor, which can create an environment where insects and rodents like to live. Seal all leaks, and watch for holes anywhere in the system. Even tiny holes can be access points for insects in search of water. Make sure all vents and ductwork are properly covered.

When you use integrated pest management strategies, you reduce the need for dangerous chemicals that threaten the health of your employees and harm the surrounding environment. This is an easy way to help your facility go green.

Use Higher Quality Lubricants and Fluids

Many air compressor systems need some type of synthetic lubricant to run smoothly. However, if water escapes the air compressor unit, it may be contaminated with small amounts of these lubricating fluids. If water and fluids leak from your air compressor system, and they are not properly contained, they can eventually contaminate groundwater and nearby waterways. Incorrect use of the air compressor or damaged components can increase the risk of leaking lubricants and other fluids.

The first step towards greening this part of the system is to fix any leaks that you can. You should also attempt to contain any fluids coming out of your air compressor system. Any water and other fluids should be disposed of properly, not used to water plants or dumped down the drain. The residual lubricant fluids can contaminate municipal water, so this should be avoided. Don’t allow fluids to drip out of the system and just run off into floor drains.

The other important step is to switch to higher quality, more eco-friendly lubricants and fluids. Whenever possible, you should use fluids that are more sustainable and better for the environment. But even using a higher quality synthetic oil is better in the long run because it can help the air compressor system run more efficiently, meaning less wasted energy and maintenance costs. Using incorrect or lower quality fluids can damage the whole system over time, cause runoff and have a lower efficiency overall. These inferior fluids can leave behind buildup or cause corrosion inside the air compressor. Make sure you are using the best possible lubricants for your air compressor model.

Upgrade Your Air Compressors

Sometimes the best way to go green with your air compressors is to replace them completely. If your air compressors are old, and you find that they need frequent repairs, it may be time to consider replacements. Air compressors that constantly need repairs or frequently spring leaks can lead to all of the problems discussed above.

Newer air compressor models will operate more efficiently, need far less maintenance and repairs and should comply with the new governmental standards of operation. Look at your options for new air compressors, and choose a new model that is more efficient to run and known to be an eco-friendly option.

Variable Speed Air Compressors From Quincy

Since 1920, Quincy has produced some of the best air compressors on the market and is proud to provide air compressors to industries and businesses all over the world. Today’s standards for air compressors trend toward more eco-friendly options as companies look to reduce their carbon footprint and work on going green. We are pleased to offer high quality, eco-friendly options for air compressors, including variable speed air compressors suitable for a wide variety of industries. We designed our air compressors to maximize efficiency, reduce energy consumption and have a long lifespan with little maintenance needed. Contact Quincy today for more information on these innovative air compressors, or find a dealer near you.