In order to keep your compressed air system fully operable and efficient year–round, it’s crucial to prepare your compressor for each season. As part of a process referred to as “weatherization”, experts on compressor maintenance suggest biannual inspections of various points along a compressed air system.

When it comes to air compressors, weather extremes can be detrimental to the performance of internal mechanisms and end tools if faults along the system are allowed to fester. Some of the most troubling ailments in this regard include air leaks, clogged drains and dirty filtration systems. Read on to learn of ways to prevent these problems and prepare your compressor for each season, including the hottest summers and coldest winters.

Eight Easy Steps to Prepare Your Compressor for Each Season

An air compressor is capable of working under all types of weather, providing that the compressor is kept in optimal shape and the operating environment is suited to the technology. With periodic maintenance of your compressed air system and its room of operation, you could enjoy optimal performance throughout the year with minimal downtime. Therefore, it’s wise to mark each of the following steps onto select seasonal dates of your working calendar.

Contact Us Learn More Find a Dealer Near You

#1. Check the Drains

As weather gets warmer during the months of summer, condensation levels are bound to increase within an air compressor. When this occurs, it can be problematic on numerous levels, because moisture can impact the performance of pneumatic tools and also erode the mechanisms within an air compressor.

If the drains fail and water buildup gets out of hand, it could spoil a production or even cause an air compressor to shut down. Condensate is particularly troublesome for spray paint operations, especially when misty air transports aerosolized oil to the end point.

Check the drains to ensure that they function optimally for the heightened demands placed on the compressor once temperatures spike. Make sure that the water passes out without any backup or blockage, and that the drains are capable of handling the increased flow of water from the air compressor.

On a side note, oily water shouldn’t be released into the drain of the air compressor. Therefore, the condensate should first be treated before it makes its way to the drain. In order for this to occur, the treatment system and filters within the compressor must separate the oil from the water. To ensure that oily condensate doesn’t filter into the drain, check the oil separators to ensure that they’re working properly.

#2. Clean the Coolers

The temperature that surrounds an air compressor is integral to the quality of the machine’s performance. If the air that surrounds the compressor is hotter than normal due to rising outdoor temperatures, it can affect the performance of pneumatic tools and machines. Therefore, it’s crucial to ensure that the air compressor itself maintains consistent temperatures throughout the year, including those months where outdoor temperatures top 80 degrees.

In order to prevent an air compressor from getting hotter during summer, the coolers must be cleaned each year just as temperatures begin to rise. If the coolers are clogged, it could impede their ability to keep your compressed air system at desired levels. To prevent this from happening, perform the following actions several weeks in advance of each summer:

- Inspect the coolers for traces of dirt, gunk or misty residue.

- Clean away any dirt deposits present on the coolers.

If the air compressor gets overheated, the impact could be troublesome for the compressor itself, as well as for any attached pneumatic tools and machinery. If a compressor is used to power air blowers, for example, the quality of air that reaches the end point could be ill–suited to the task at hand when the system is overheated.

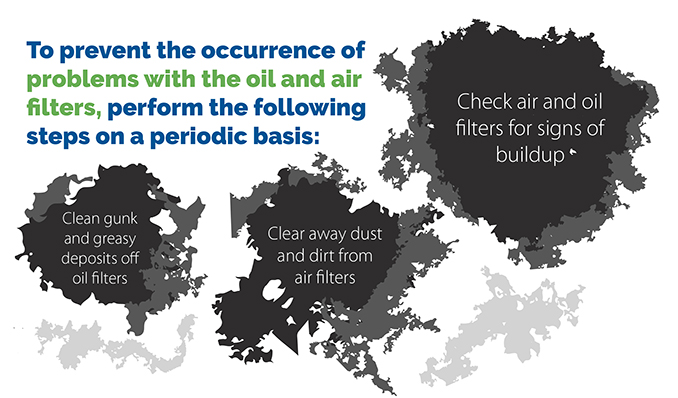

#3. Clean the Air and Oil Filters

The filtration system is integral to the efficiency of an air compressor. As long as the air and oil are sufficiently filtered throughout a given cycle, the air compressor can be expected to produce cool air at consistent volumes with an overall smooth performance from the machine. However, if the filters are clogged with dirt, pressure drop can ensue, and this forces the air compressor to work harder just to perform basic functions. Consequently, energy gets consumed and parts get worn in the process.

If gunk and dirt are allowed to accumulate over several seasons, the decline in air quality could serve as a warning sign of costlier problems down the way with an air compressor. To prevent these problems from occurring in the first place, check the filters regularly and clean them out as needed.

#4. Check the Ventilation

Maintenance of an air compressor unit is only part of what keeps a compressed air system in optimal condition throughout the four seasons of a given year. In order to keep a well–functioning compressor performing up to par, you also need to ensure that the compressor room is maintained with optimal working conditions for the machinery contained within.

As with the air and oil filters within the air compressor, it’s important to check the ventilation for the room that houses the machine. To prevent the ambient air from becoming too congested, perform the following steps on a routine basis:

- Check air vents for dust deposits.

- Clear away dust buildup from air vents.

- Inspect the HVAC system for dust buildup and defects.

In any kind of work environment, the air needs to circulate in order to remain healthy. Even if you have an HVAC system in place that’s been especially programmed to maintain suitable temperatures and ambient air quality inside the room that stores your compressed air system, the HVAC unit itself could become compromised if not subject to periodic inspections. This, in turn, could degrade the quality of air within the compressor room and have a domino effect on the compressor and related tools. All such problems can be prevented with routine inspections of the air vents and HVAC system.

#5. Adjust the Water Cooling System

When water is the cooling factor in any kind of air system, the water itself must be cool in order for it to have the desired effect. When the weather gets warmer, the water that goes in should be even cooler. Just as with air coolers, a water–cooled air compressor needs sufficiently cool water to offset the ambient warmth during hotter months.

To ensure that the water in a water–cooled air compressor maintains sufficient coolness, perform the following actions before each working cycle that takes place during humid days:

- Check the temperature of the water.

- Adjust the water temperature if necessary when ambient temperatures rise.

With any machine that has been made to supply quality air, external factors can impact the performance of the machine and the quality of air that reaches the end point. In the case of a water–cooled air compressor, the quality of compressed air is liable to be compromised if a normally cold water supply is rendered warmer by humid ambient temperatures. To prevent such problems from occurring, check the water supply during hotter months to ensure that the water temperature remains consistent with fall, winter and spring levels.

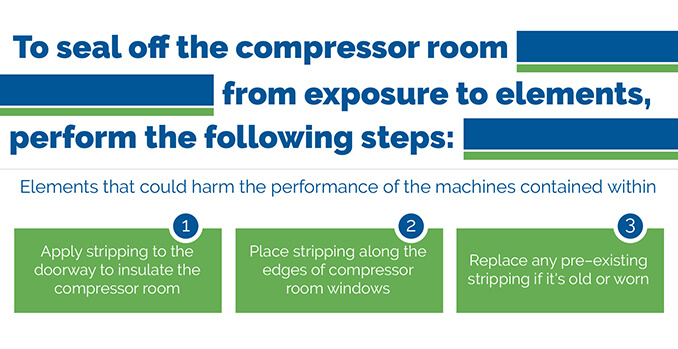

#6. Check the Weather Stripping

The performance of a compressed air system is inevitably affected by its surrounding environment. If unwanted elements are slipping into the room in which the air compressors are situated within a given facility, the compressors are liable to be somewhat compromised in their performance, regardless of any maintenance that might be performed on the machines in question.

In an insulated room, the quality of air can be compromised by any given number of overlooked factors. For example, if small gaps exist around a door when it’s shut, air is going to pass between that door no matter how tight it’s locked. By the same token, gaps around a window — regardless of how slight they might be to the naked eye — will cause conditioned indoor temperatures to be diluted with slivers of airflow from the outside. To prevent these factors from compromising the air quality in your compressor room, apply weather stripping as needed.

v#7. Check the Insulation

For all the questions about seasonal maintenance that primarily apply to select months out of a given year, there are certain maintenance protocols that apply year–round, such as insulation upkeep. In the rooms where compressed air systems are operated, insulation must be maintained during the humid summer months, as well as through the cold of winter. If temperatures that are either too hot or too cold for ideal operations leak into the facility from the outside, the affects could compromise the performance of an air compressor and lower the quality of productions.

In order to prevent the dilution of air insulation within a compressor room, perform these inspections in advance of each summer and winter:

- Check for gaps between the walls and window sills.

- Inspect the doorways for gaps along the top, bottom or sides.

- Inspect the walls and ceiling for holes and cracks.

One of the most elusive problems that can occur with compressor room ventilation is the passage of air through small slivers and cracks in unexpected places. These cracks or holes could be located along the wall, ceiling or especially along the trimming. Inspect these areas semi–regularly and patch up any holes or cracks that do materialize.

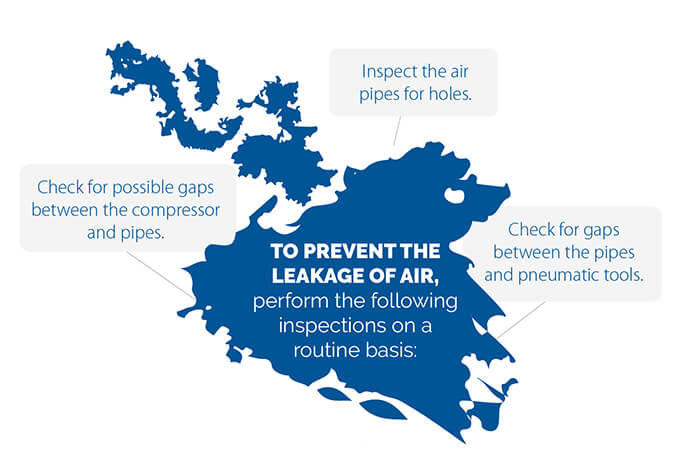

#8. Identify and Fix Air Leaks

Regardless of the season or the outside temperatures, air leaks are the ultimate enemy of a compressed air system. An air compressor could have perfectly functioning filtration and be free of condensate or traveling oil, yet still lag in its performance if air leaks are present at any point between the machine itself and the tools at the end of the pipes.

When air leaks form along a compressed air system, tool performance weakens and operations become less efficient. If an operator is unaware of the problem source, the first solution that often comes to mind is to simply crank up the pressure on the system in order to compensate for the lagging power. This, in turn, leads to increased wear and tear on the internal mechanisms of an air compressor.

Simply put, there’s nothing to be gained from leaks in a compressed air system. The problems associated with leaks are easier to spot and remedy, or prevent altogether, with routine inspections along all the parts that transport air from the compressor to the end tools.

Buy Air Compressors for Year-round Performance from Quincy Compressor

When summer temperatures are at their peak, ambient air contains infinitely more water than the cooler air of fall, winter and spring. For obvious reasons, this can be troubling for compressed air systems if maintenance protocols aren’t enacted in advance of each hot spell.

Then again, freezing temperatures can also be troubling for a compressed air system, particularly for applications that rely on even–tempered ambient settings. As such, weatherization of your air compressor should be thought of as a year–round concern with maintenance undertaken every six months, at minimum, preferably in the late weeks of spring and fall.

For air compressors with the power to work at maximum efficiency through all seasons of a given year, people turn to Quincy Compressor. For nearly a century, Quincy has been the world’s leading provider of compressors that work in all seasons and climates. From pressing–plant operations to garage–based crafts and repairs, Quincy makes air compressors and pneumatic tools that keep the world productive.

At Quincy, we sell air compressors that drive a vast range of vital year–round operations, including food packaging, construction and auto assembly. To learn more about what our compressors can do for your operations, click on over to our sales and service page to contact a local dealer.