A natural gas compressor increases the pressure of a gas by reducing its volume. The natural gas enters the cylinder through the intake valves, where it is compressed and forced out through discharge valves. A gas air compressor is one form of natural gas compressor that is used in a wide range of industrial applications where either high pressure or lower volumes of gas are required. Examples include:

- Petroleum refineries, natural gas processing plants and chemical plants: Used for the compression of intermediate and end-product gases

- Industrial manufacturing and building: Provides compressed air that powers various pneumatic tools and equipment

- Pipelines: Transporting natural gas from the production site to the end user

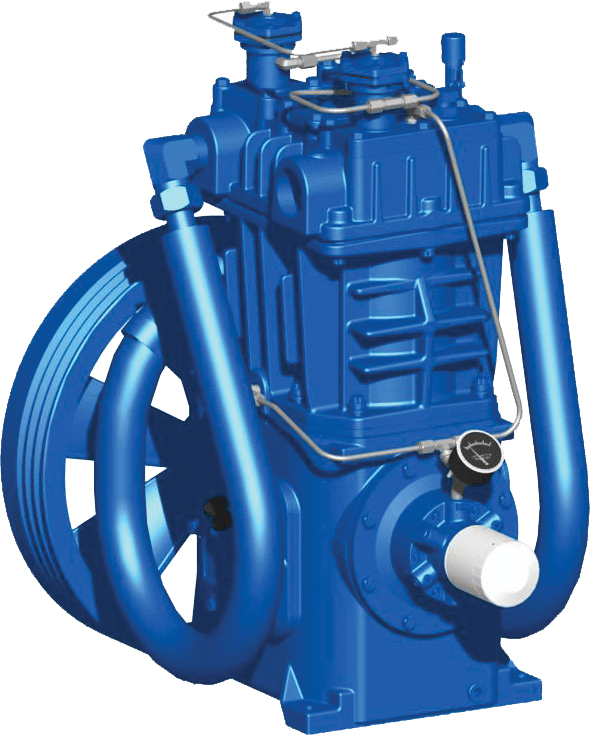

QRNG Reciprocating Natural Gas Compressor

A reciprocating gas compressor uses crankshaft-driven pistons to provide compression. The thrust is provided by a positive displacement pump that moves the gas through the system and enhances the gas’s pressure and density. Benefits of reciprocating gas compressors include their ability to produce high power and high pressure compressed gas, as well as the absence of an oil carryover problem. Reciprocating compressors also generally require a lower initial investment than other compressor types.

- 2-34 hp

- Single & Two-Stage

- 400 psig max discharge

Download the brochure Request a Quote Buy Parts, Fluids / Oil

Quincy Compressor: The Leading Gas Air Compressor Company

As an experienced and innovative gas compressor manufacturer and supplier, Quincy Compressor is your best choice for reliable, high-performing reciprocating and rotary gas compressor models. Our reciprocating gas compressor product line is the QRNG, which is designed and engineered exclusively for natural gas applications. Nine QRNG models are available, including single-stage and two-stage versions that provide cost-effective gas compression, fast and easy maintenance and heavy-duty cast iron construction.

Contact the authorized Quincy Compressor distributor in your area to learn more about our natural gas compressor solutions, or find one of the authorized packages to evaluate your needs.

Keep your reciprocating natural gas compressor running smoothly with proper oil and maintenance.

Follow the link to learn more about natural gas rotary screw air compressor horsepower.