A refrigerant air dryer performs the essential function of removing water vapor and the contaminants it carries from compressed air. Quincy’s refrigerated air dryers purify compressed air by chilling it to approximately 37 degrees Fahrenheit. This process causes moisture to condense. Condensed moisture carries airborne dirt and oil to the separator, where an automatic drain removes it from the air stream. We offer a wide selection of state-of-the-art air compressor dryer products, including non-cycling, cycling, variable speed, and compact high-temperature dryers for many industrial applications.

How Do Refrigerated Dryers Work?

Atmospheric air will always have some level of moisture in it, and compressed air can also have invisible particles of dirt and oil, which may damage your air tools and machinery. The normal pressurization process heats the air, often to around 100 degrees Fahrenheit. High temperatures force the vapor to condense and form liquid droplets, which may harm your equipment. Air treatment including filters and refrigerated dryers solves this problem, extracting moisture to produce clean, dry air.

Here’s how refrigerated dryers work.

- Air enters the refrigerator and travels to an air-to-air heat exchanger. Here, the outgoing cold air pre-cools the warm air.

- Next, the air enters a refrigerant-to-air heat exchanger, which cools it to around 37 degrees Fahrenheit.

- The water droplets separate from the cold air, and the unit expels the moisture. Draining also removes dirt and oil.

- Finally, the air passes back through the air-to-air heat exchanger. The incoming warm air reheats the cooled air leaving the air dryer. The newly dried air has a pressure dew point somewhere between 35 and 50 degrees Fahrenheit. See specifications for each Quincy model to find out the exact dew point for a particular dryer.

Types of Refrigerated Dryers

Refrigerated dryers generally fall into two categories: cycling and non-cycling dryers.

- Non-cycling dryers: In a non-cycling dryer, the refrigerant circulates throughout the system at the same rate, regardless of the load of the air entering the dryer. Because ambient air temperatures and compressed air flow fluctuate, a hot gas bypass valve regulates the temperature to prevent the machine from freezing. Non-cycling dryers work best paired with rotary screw air compressors.

- Cycling dryers: A cycling dryer cycles on and off in response to the air entering the machine. This type of dryer stores cold energy until a needed time, which helps conserve energy. Cycling systems typically sense when the inlet air mass reaches a specified temperature. The system will then turn on and cool the air until it reaches the desired low temperature. After it achieves this temperature, the system automatically turns off. Since these systems only use the amount of energy required to cool the inlet air, they are even more efficient.

- Variable speed dryers: Variable speed dryers are the most energy-efficient dryers in the market. These dryers speed up or slow down based off incoming air demand. Because they are not constantly running at full flow and only operating at the capacity required at any given time, no energy is wasted. Also, variable speed technology allows for a constantly stable dew point even in harsh environments.

When deciding which type of refrigerated dryer is right for your facility, it’s essential to weigh initial cost and lifetime cost. Non-cycling dryers will be the most affordable upfront. Cycling and variable speed dryers, on the other hand, save on energy costs over time. All work well for most manufacturing applications.

Benefits of Refrigerated Dryers

There are many excellent advantages of refrigerated dryers.

- Ideal for moisture-free applications

- Avoid corrosion to your systems caused by moisture

- Prevent rotting in woodworking applications

- Extend the life of your compressor

- Low maintenance

- Save on energy and upfront costs

QPNC Non-Cycling Dryer

Best Suited for Smaller Systems Expecting Fairly Constant Loads

These units use a two-stage heat exchanger to maintain consistent dew points. The system prevents freeze-ups and sustains optimum performance. The QPNC non-cycling compressed air dryers work by lowering the air temperature to 39 degrees Fahrenheit, which causes the condensation of entrained moisture. The moisture then makes its way to the specially designed moisture separator, which removes all liquids. The cold, dry compressed air then returns through the first-stage heat exchanger for reheating by the incoming warm air.

The QPNC features a non-cycling control panel, which provides smooth and efficient operation. It also includes zero loss drains for maximum energy efficiency. The 10-year heat exchange warranty gives you comprehensive protection and peace of mind.

- 39 degrees Fahrenheit dew point

- 10 to 4,000 cfm

- 150 psig max

- Non-cycling flow schematic

QED Cycling Dryer

Most Efficient Drying Technology Available

Quincy’s Eco Dri Cycling compressed air dryers are a reliable component of almost every industry where dry, contaminant-free compressed air is a necessity. These units save energy by cycling the refrigeration on and off in response to demand. A three-stage heat exchanger system provides the cold storage necessary for the operation.

Besides improving the quality of the compressed air, our cycling dryers feature a compact design for maximum placement flexibility. They’re also simple to operate and extremely energy–efficient, and they provide steady RH for excellent corrosion control. Unlike less technologically advanced models, Quincy cycling dryers do not require cooling in a glycol bath. Their design automatically adjusts to account for changes in the operating environment. They come with a two-year full-coverage warranty, as well as an industry-best 10-year heat exchange warranty.

- 35 degrees Fahrenheit dew point

- 10 to 4,000 cfm

- 150 psig max

- Cycling flow schematic

QPVS Dryer

Most Efficient Drying Technology Available

Quincy’s variable speed compressed air dryers are the most energy-efficient air dryers in the market. These dryers speed up or slow down based off incoming air demand. Because they are not constantly running at full flow and only operating at the capacity required at any given time, no energy is wasted.

As the incoming compressed air fluctuates, the variable speed drive recognizes the change in demand and jointly slows down or speeds up to match demand. By using this technology, the QPVS saves up to 60% on energy when compared to non-cycling dryers, and it can stabilize the dew point by reducing dew point swings that are traditionally seen with thermal mass dryers. They come with a two-year full-coverage warranty, as well as an industry-best 10-year heat exchange warranty.

- 37 degrees Fahrenheit dew point

- 210 to 8,500 cfm

- 210 psig max

Quincy Testimonials

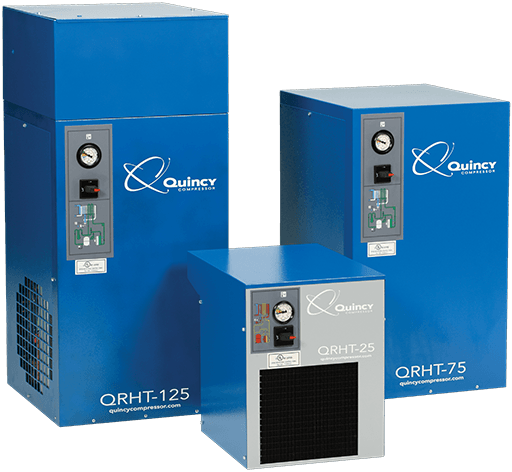

QRHT Compact High-Temperature Dryer

Accepts 180 Degrees Fahrenheit Inlet Temperature

The revolutionary QRHT air dryer for air compressor applications features five components, each of which performs a separate but vital action. Although they operate separately, the functions blend precisely to provide clean, dry compressed air. These dryers eliminate water, oil and dirt from air systems, preventing damage to pneumatic tools and cylinders. The result is fewer product defects and no “fisheye” paint splotches in applicable operations. We recommend these dryers for most piston reciprocating compressors with high discharge temperatures.

The Quincy QRHT line includes five models that provide a maximum psig of 232. Depending on the model, the cfm@100 psig ranges from 25 to 125. Besides effectively eliminating moisture, oil and dirt from the air, a Quincy QRHT refrigerated compressed air dryer provides many hours of trouble-free operation and reduced operational downtime. It may also increase productivity and profitability throughout your facility.

- 39 degrees Fahrenheit dew point

- 25 to 125 cfm

- 175 psig max

- Space-saving three-in-one design

Learn More About Quincy Compressor’s Refrigerated Air Dryers

At Quincy Compressor, we back our products with nearly 100 years of air compressor industry experience. Your local authorized Quincy Compressor distributor will be happy to provide additional details about our complete line of refrigerated air dryer models. You can also contact us directly for more information.