Throughout many industries and businesses, tools and machinery are powered by compressed air. Reliable and powerful, compressed air processes are essential for keeping today’s businesses running.

However, compressed air systems are often the most taxing systems for a shop’s energy consumption.

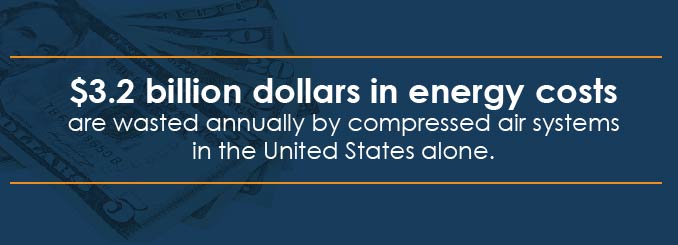

Consider these statistics from the Compressed Air and Gas Institute (CAGI): Its estimated that in the United States alone, $3.2 billion dollars in energy costs are wasted annually by compressed air systems. This number only accounts for the amount of energy lost through inefficiency, not the energy converted into usable compressed air power.

That’s because too often, businesses and factories fail to audit and log their compressed air performance efficiency. In other words, they are wasting power and they don’t even know it.

Contact Us Learn More Find a Dealer Near You

Getting the Most From Your Compressor

Improving the energy efficiency of compressed air systems likely only requires small functional adjustments. For example, according to CAGI, on average, compressed air systems only need to be working at full capacity for 60 to 100 hours a week. However, most businesses do not adjust the output of their systems accordingly, meaning the system is running at 100% power for the full 168 hours of the week. In other words, compressed air systems are running at 100% when 50% would be more than sufficient. By simply turning off a compressor when it isn’t needed, a business could cut its energy costs in half.

At Quincy Compressor, we believe in the value and power of compressed air systems. We know they are the best way to keep operations performing at top efficiency while limiting downtime, all of which combine to keep industries running and profits soaring.

We want to help you get the most out of your compressed air system. And one of the best ways to accomplish this goal is to collect the data necessary to spot inefficiencies and make the small adjustments that will save you a lot of money in the long run.

That’s why we’ve put together this guide on the reasons to log and audit your compressed air system. By incorporating these best practices into your compressed air processes, you will be well on your way to operating at peak efficiency, which will both save you money and help reduce your energy consumption.

First Start With a Baseline

If you want to chart out the path toward improved energy efficiency, you must first establish your starting point.

Any measurement of energy efficiency follows a basic principle:

- How much energy, in the form of electricity, is being used

- What is the resulting compressed air power output of the system

In regards to electricity usage, the relevant units of measurement are kilowatts (kW), which is the raw amount of power being consumed, and kilowatt hours (kWh), which is a standard unit for understanding energy consumption.

A kWh represents 1 kW consumed over one hour. So if you use an appliance that consumes 100 watts, or .1 kW, over the course of an hour, and you use that appliance for 10 hours straight, then that appliance would be seen as using 1 kWh. Understanding the kWh usage of your compressed air system is important because kWh is the measurement used for billing by energy companies.

Additionally, when you are establishing your baseline, you want to establish how many kilowatts of power are needed to establish the level of compressed air necessary to power your operations. Compression power is measured in cubic feet per minute (cfm), so conversion of electrical power into compressed air power is measured by the unit kW/100 cfm, or the number of kilowatts necessary to produce 100 cfm.

It is this last unit, kW/100 cfm, you want to lower in order to improve energy efficiency and thus save money. In order to establish your baseline energy efficiency, data sets are collected over a period of at least two weeks. This baseline provides you with an idea of how much energy is being used on average. This average gives you actionable data moving forward.

Know Your Baseline

You can compare your baseline to the standard rating of the system you are currently using. While there are a number of variables that can cause small deviations from the rating, if your individual system is not performing close to the level established by the manufacturer, you know there is a problem.

It will also help you detect smaller, momentary deviations from your baseline. If you find over the course of the week there are moments when either the energy efficiency is greatly increased or hindered, you can then begin to investigate which processes might be causing that change.

Finally, this baseline is important if you are looking to access energy efficiency financial incentives. Whoever is offering the incentives in question will want to see your baseline in order to ensure you are making measurable improvements.

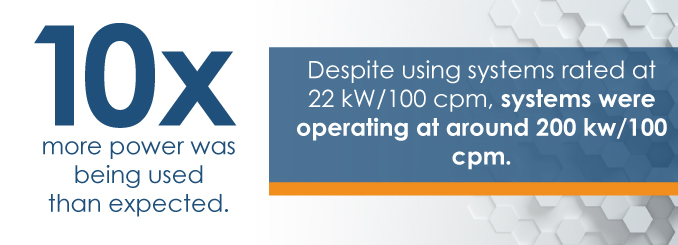

By simply setting a baseline, many businesses have identified how remarkably inefficient their systems were operating. As an example, Compressed Air Best Practices, a trade magazine focused on providing advice for compressed air systems users, looks at a certain rocket fuel production company. Despite using systems rated at 22 kW/100 cpm, when it identified its baseline, it saw its systems were operating at around 200 kw/100 cpm, meaning it was using nearly 10 times more power than it was expecting to just to keep its air compressors running.

Although finding your baseline is only the first step, even doing that can go a long way in providing you with guidance moving forward.

Use Continued Monitoring to Provide Accurate Adjustments

While air compressor systems are ideal for most industry applications, they are only as good as their ability to provide sustained, dry, high-pressure air. Whether a system is bearing an expectedly heavy usage load or there is a small, unseen leak sapping air pressure, if the pressure isn’t there, you either have to stop working or systems operators have to increase the pressure.

However, you’d be surprised at how haphazardly this process unfolds in most factories. In the average shop, when a tool becomes underpowered, whoever is using that tool calls the compressor operator by phone and asks for more power. The operator then turns up the pressure with little concern for efficiency or precision.

Logging allows you to make much more precise adjustments that will pay large dividends in the long run. Why increase the pressure in the system by 25% when a mere 5% increase would do?

Logging also helps identify redundancies that can be eliminated. This is especially useful in shops that operate more than one air compressor:

- If your manufacturing operation has a reduced number of workers during certain shifts, it is common practice to turn off a compressor during the smaller shift. However, this is an imprecise approach.

- While a plant may save significantly by reducing the number of compressors in use in correspondence with shift changes, there may be additional time when fewer compressors are needed.

- For example, after collecting data, a company may find that an additional compressor is not necessary until an hour into the larger shift. Because of the way operations are ramped up during the larger shift, it may take additional time until the plant is working at full capacity.

- By leaving the extra compressor down until it is absolutely needed, a company can find additional and significant energy savings.

Finally, it is important to continue monitoring even when compressors are off. Turning compressors on and off can have unexpected effects on power consumption. The power-on process may be unnecessarily taxing on electricity usage, in some cases using almost as much power as what was saved by having it powered down. It is important you collect data for the entire usage cycle of your compressors so you can identify such problems and address them immediately.

Collect Data to Accurately Identify Pressure Stability Events

Pressure stability events — in which air pressure is lost seemingly at random — can wreak havoc on plant operations. Perhaps these events will be corrected by ramping up compression. While that may keep the plant moving, it is terribly energy inefficient. Perhaps a plant will temporarily stall operations until pressure stabilizes. Unfortunately, as anyone in manufacturing knows, even a minute or two of downtime can have a significant impact on profits.

However, with enough data, the cause of these seemingly random events can be uncovered. Perhaps it is one tool, sparingly used, that causes a pressure drop when put into operation. By fixing that particular tool, the problem can be solved.

Or perhaps there is an issue with the electrical source for the compressor system that occurs at regular intervals throughout the day. This is an issue that needs to be addressed in cooperation with the electrical company. In order to prove your case, the electrical company will want to look at available data to ensure you have in fact found the root of the problem.

That being said most cases of unexpected pressure loss are caused by the cycling of motors and internal systems within the compressor system. Breaking down and tinkering with a malfunctioning compressor is a time-consuming and expensive proposition.

However, with robust data logging, repairs can be conducted with surgical precision. If a correlation between pressure loss and a certain system cycle can be identified, the service provider can tackle the components that drive that cycle while avoiding other systems that are irrelevant to the pressure loss.

Employ Data to Reveal Unexpected Problems With Simple Solutions

Compressed Air Best Practices cites a curious example of mysterious pressure loss that was solved through data logging. In a certain plant, the compressor was experiencing unexpected and inexplicable pressure events. The service contractor was brought in, and despite breaking down the compressor and analyzing countless components, the contractor could not identify the cause of the pressure loss.

However, after pouring over the data logs, it became clear the pressure loss was happening either directly before or directly after a shift change. So they started brainstorming about how the shift change could be affecting the pressure. They soon realized the actual compressor was installed in the vicinity of the changing room. Because it was so loud, one employee had taken it upon himself to flip the switch on the compressor when he was changing.

Even though at first glance the problem seemed to be mechanical, it was in fact due to an unexpected human error, an error that would have been humorous had it not also cost dearly in both time and money. By simply locking and limiting access to the compressor, the problem was solved.

Use Data to Demonstrate How Much is Being Saved

For those who are constantly striving to improve energy efficiency, data is the verification you need in order to justify your efforts.

This is important because, while air compressors are inspected and accurately rated by the manufacturer, if you are investing in a particularly energy efficient compressor system, you should know ratings reflect a perfectly functioning system. If there are issues, your energy-efficient system may not be performing any better than a standard compressor.

Furthermore, in order to achieve energy efficiency, many of these top-of-the-line compressors have additional and more complicated systems designed to limit power consumption when pressure isn’t needed. However, with more moving parts, there are more opportunities for things to go wrong.

So if you are truly serious about energy efficiency, don’t take it for granted. Use data logging to make sure you are constantly operating at peak performance.

Pick the Perfectly Sized Compressor With Data

Finally, if you are looking to replace an aging compressor with a new system, data is your best tool for making sure the new compressor is perfectly sized for your operation. This is especially important because imprecise data can lead you astray.

Turning again to an example from Compressed Air Best Practices:

- A metal fabricator noted it had a 150 hp system that was typically running at 20% capacity. In other words, it was using a 150 hp compressor while only needing a 30 hp. However, in running the numbers, it discovered there was a particular process that was rarely used but essential that elevated the compressed air flow to 50%.

- Had it purchased a 30 hp compressor, every time it initiated this particular operation, it would be woefully underpowered.

- By using data, it was able to downsize its compressor, but not to such an extent as to choose a system that was severely undersized.

Follow a Regular Maintenance Schedule

Besides helping monitor energy efficiency, keeping detailed logs and audits allows you to follow a regular maintenance schedule for your facility’s air compressors. These maintenance routines are critical for getting the most from your compressor and ensuring the longest system life spans. Performing compressed air audits or assessments at the recommended intervals enables you to proactively recognize the issues increasing your operational expenses.

Regardless of a company’s size, each operation needs a dedicated staff member to oversee daily maintenance responsibilities for the compressors, including logging each repair and documenting when the daily, monthly or annual maintenance requirements occurred. Whether your company’s team or an air expert from Quincy Compressor performs repairs or modifications on your compressor, you know you’re taking the proper steps to ensure reliability and efficiency.

Several additional benefits of following a regular maintenance schedule and documenting each action include:

- Minimizing downtime: Without the appropriate monitoring, system problems show up at the most inopportune times. Preventive maintenance identifies minor issues that can worsen later and shut your system down entirely. Following a daily, monthly and yearly maintenance checklist according to your system’s guidelines helps avoid unexpected problems, even if nothing appears wrong.

- Avoiding costly repairs: When you minimize production downtime, you save money. Allowing minor issues to worsen before you address them typically results in more expensive system repairs. The money you save by performing and documenting your maintenance requirements enables you to increase your company’s bottom line by purchasing more efficient equipment or increasing employee wages.

- Increasing your system’s life span: The longer your system operates efficiently and accurately without significant repairs, the higher your return on investment. Without regularly scheduled maintenance, an air compressor system and its components will not last as long as they otherwise would with the recommended checkups. Logging each activity ensures you address each maintenance or service interval in a timely fashion.

Regular air compressor maintenance allows you to identify cases when the system is over-exerting or struggling to maintain the expected production rate. When issues like these arise, they typically involve lubricating, cleaning or replacing one or more system components. Identifying these issues before they grow out of hand enables the compressor to run more smoothly and efficiently for longer, translating into increased savings.

Examples of the most critical system components requiring regular lubrication, cleaning and inspection include:

- Oil filters

- Air filters

- Belts

- Motor bearings

- Intake vents

Turn to Quincy Compressor

As the industry leader in compressed air systems, we know how important accurate data logging is. That’s why our systems are designed to make data collection easy. We want to help you get the data you need to improve your systems and address any and every concern you may have in the future.

We also provide services to assist you in collecting data and achieving that all-important baseline. We provide top-of-the-line auditing services, including our award-winning EQ: Energy Quotient service to help you know exactly where you are starting while giving you the tools to move forward with your energy efficiency plans.

In the end, we believe in the power of air compressors for getting the world’s industries working. And we want to put our belief into action by equipping all of our partners to be more energy efficient, helping them save money while doing our part to reduce energy consumption.

Contact Us Learn More Find a Dealer Near You

Last Updated on July 31, 2023 at 3:00 PM