Mist Eliminators

Unique Double Element Design How it Works The Quincy Mist Eliminator is a heavy-duty coalescing type filter engineered to efficiently remove oil, particulate, and water from compressed air. By using a combination of impaction, interception and Brownian Movement, the Quincy Mist Eliminator achieves 100% efficiency in removing particles 3 micron and larger, 99.98% of 0.1 […]

Read MoreBuying A New vs. Used Air Compressor: Which One Is Best?

When you need an air compressor for your operations, you have a choice to make — will you buy new or used? This comes after deciding the specific type of compressor you need, from rotary screw to reciprocating, so making another decision may be overwhelming. There are plenty of pros and cons for either type of […]

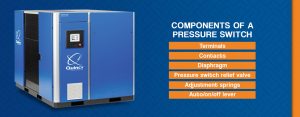

Read MoreWhat Is an Air Compressor Pressure Switch?

The air compressor pressure switch measures the pressure inside your air tank and shuts off your compressor when it reaches the air pressure you need. The air compressor pressure switch will also help your machinery maintain the proper pressure level as you go about your work. The switch can turn on your compressor when tank air pressure levels drop and more air […]

Read MoreGuide to Air Compressors for Microbreweries

If you know anything about brewing beer, you probably know the main ingredients. Water, yeast, hops and grains create the base of countless brews. But there’s another essential component you might not have considered — air. As you prepare to start a microbrewery or enhance your current setup, you’ll probably wonder — what equipment is needed for a […]

Read MoreThe Benefits of Air Compressor Training

For many companies, compressed air is seen as one of the most expensive utilities. An industrial air compressor can mount operations costs of more than $800,000 in electricity over ten years. What’s worse is that much of that electricity is wasted. A typical air compression system loses about half of its air to leaks, poor […]

Read More7 Steps to Save Energy and Money With Your Compressed Air System

7 Steps to Save Money and Energy with Your Compressed Air System In today’s competitive world, cost control is the key factor to turning a profit. Air compressors can blow away money from your production budget if they are not properly maintained. Leaks and worn parts reduce the pressure your compressor can produce. Worn seals […]

Read MoreAir Powered Tools

The power from an air compressor is used for a variety of applications. From the power-hungry industrial purposes of conveyor operation, pharmaceutical production or plastics manufacturing to the simple personal uses of inflating tires and equipment cleaning, you will find pressurized air working in all sorts of ways. What Are Pneumatic Tools? One of […]

Read MoreA Guide on When to Fix or Replace an Air Compressor

Compressed air systems form the backbone of industrial manufacturing, are an essential component of medical facilities and are even responsible for keeping commercial food services running. Needless to say, many of the things that Americans have come to take for granted are only possible with the assistance of compressed air. Compressed air systems provide consistent, […]

Read MoreWhat You Need to Know About Air Compressor Duty Cycles

Air compressors are purchased for different reasons by a wide range of companies and independent craftspeople. In some cases, a customer might expect to get a continuous duty cycle air compressor when making that initial investment, only to find the machine in question merely offers a 50% duty cycle. Therefore, it is important to know about duty […]

Read MoreWhat Is Ambient Pressure and Why Is It Important?

Factories and workshops around the world use air compressors to power tools like grinders, spray guns, sanders, staplers, nail guns and drills. Though air compressors have many applications, optimal working conditions for compressors remain constant. Ambient temperature and ambient pressure — also known as “inlet pressure and temperature” — significantly impact an air compressor’s performance. These terms refer to the temperature and density […]

Read More