Air compressors in space are the unsung heroes of every mission. But we’re big fans of air compressors and of space, so we thought we’d share a little bit about how space agencies like NASA are using compressed air in outer space.

If you wanted to fly to the moon, you’d probably think a lot about liquid fuel in giant tanks and lots and lots of thrust. But, if you forget to add in compressed air, you won’t get anywhere safely or efficiently. Air compressors in outer space keep all of our astronauts alive from the liftoff of the shuttle to breathing properly during their entire journey and during re-entry.

Air compressors in space engines play a significant role in the future of travel because they’ll allow systems to be smarter, more efficient and lighter. While new technologies are being created and adopted each day in space, compressed air remains a constant.

Heat Pumps: Using Air Compressors in Space Instead

Oil-less compressors are currently used by the International Space Station’s heat pump system, but they’re “gravity-insensitive.” This means the compressors are able to compensate for problems that would’ve normally led to cooling materials — such as oil in some compressors — that could pool or flow in a nonstandard direction.

Astronauts are using this compressed air in outer space to manage their air supply, perform experiments, keep the boosters running efficiently so vehicles and space stations stay in orbit and maintain a comfortable temperature for everyone on board.

For example, fluids that normally mix and combine easily here on Earth actually break into separated beads of each fluid, even when traveling together, when they’re in space. Without Earth’s gravity, the separation of these fluids could pose a risk and cause a traditional heat pump or liquid-dependent air compressors in space to experience malfunctions.

Advances in heat pump technology have led to units that are low power and extremely efficient, making them perfect for a variety of systems on space shuttles and space stations.

Compressors that work with air and vapors are being adopted because they offer a long life and reliable use for many years, especially when compared to heat pumps that require a liquid for cooling. Liquid-based systems already have problems such as cavitation, but they pose even more risks in space because they operate differently.

How NASA Powers Rockets With Compressed Air

Compressed air plays a big role in NASA’s shuttles reaching escape velocity, which starts at 25,000 mph or about 7 miles per second.

Turbine engines power the vast majority of military and private sector aircraft in the sky today. Every turbine will rely on an air compressor that increases the air pressure before it enters a combustor. The better the air compressor works, the better the engine’s performance, especially at the point of combusting fuel, according to NASA.

Centrifugal compressors are used in these rocket air compressors as pumps. Many engines, from turbojets and turbofans to afterburners, will use compressed air to help ignite their fuel source. By passing it through a nozzle, the compressed air can reach fuel sources even during high-stress events like rocket takeoff.

Rocket Engines and Compressed Air

One of the ways NASA powers rockets with compressed air is by storing a significant amount of compressed oxygen and liquid oxygen. Pumps and valves use compressed air to push both of these compressed liquids into the combustion chamber, creating a hot blast of exhaust that serves to propel the rocket.

Essentially, an air compressor is the hidden component that ensures the fuel is mixed at the right rate and travels properly to the combustion chamber so the rocket engine gives the thrust that’s needed to enter outer space.

NASA’s Shuttle Engines

NASA space shuttles use a trio of main engines along with a solid rocket booster to generate the lift required to get the space shuttle and other vehicles into outer space. The space shuttle’s main engines will burn during liftoff and can work for up to 8.5 minutes after a launch, which is the typical duration of powered flight for the space shuttle.

All of the shuttle engines require strong air compressors — centrifugal compressors — in order to bring in compressed air to the liquid fuel for the purpose of ignition and controlled acceleration.

When the shuttle is taking off, it accelerates by burning liquid hydrogen, which is stored at minus 423 degrees Fahrenheit (minus 252.8 degrees Celsius), as well as liquid oxygen. Air compressors are required to make this operation run smoothly. The giant orange tank we all recognize with holds roughly 500,000 gallons of these liquids.

Temperatures in the main engine’s combustion chamber will rise to more than 6,000 degrees Fahrenheit (3,315.6 degrees Celsius).

The shuttle will burn through enough liquid fuel to fill a swimming pool every 25 seconds. During this acceleration, turbines are spinning about 13 times faster than those in your car when you’re cruising down the highway. That means the centrifugal compressors need to be working overtime to keep everything working properly.

That’s a big job, and how NASA powers rockets with compressed air is as much about getting off the ground as it is sustaining life support once they’re up in outer space. We’ll also cover to the practical applications of living thanks to using compressed air in outer space.

Centrifugal Compressors

Centrifugal compressors are used in many industry applications, including aerospace, because they have fewer parts that contact each other while also delivering high energy efficiency and a significantly larger airflow compared to other compressors of the same size.

That size requirement is great for spaceflight and other outer space applications because every pound and every inch can be a significant burden or blessing.

Centrifugal compressors work by drawing air into the center through a rotating impeller. Radial blades spin and bring the air in using centrifugal force, raising the pressure as well as generating kinetic energy. The kinetic air generated during this movement is actually able to be used to further improve the compression of the air.

Typically, these types of air compressors will work with ultra high-speed electric motors that drive the impellers. The good news for NASA is that this type of compressor won’t need a lot of space or an oil-based lubrication system. The dual benefit is that NASA doesn’t have to plan for oil operating in an environment where it could be super-cooled or heated, plus there is a guarantee of 100% oil-free air.

SABRE: The Next Evolution of Using Compressed Air in Outer Space

Air compressors in space often operate in traditional propulsion systems that move rockets or internal components in shuttles and space stations. However, they’re about to play a much bigger role in the future of space flight now that a SABRE (Synergetic Air-Breathing Rocket Engine) engine concept has passed the U.S. Airforce’s feasibility test.

Reaction Engines’ Skylon reusable spaceplane uses a SABRE engine to improve its propulsion because it works as a scramjet. Essentially, this means that it’ll actually reduce propellant load thanks to an ability to operate as a traditional jet in the atmosphere and then use rocket propulsion in space flight.

The dual functionality means the engine won’t need to carry as much compressed oxygen, which is used to burn its liquid-hydrogen fuel.

SABRE systems are extremely complicated, and they rely on compressed air for multiple functions. For instance, air needs to be cooled significantly before it enters the SABRE unit. In this case, we’re talking about cooling from 1,000° C (1,832° F) to minus 150° C (minus 302° F) in 1/100th of a second. Industrial heat exchangers can do this, but they can also be the size of a bus. The SABRE unit needs something small and light that it can easily carry.

After cooling, air compressors in outer space would then feed the compressed air directly into the engine’s combustion chamber to ignite its stored liquid hydrogen. High pressure is generated and gives the engine significant thrust to achieve extremely high speeds and altitudes.

Air compressors that are able to cool the air down can be made of extremely light but durable materials, which is needed for anything headed into outer space.

Breathing in Space

Breathing in space, whether you’re on the space station or in a vehicle like a shuttle, requires compressed air of varying types and compositions.

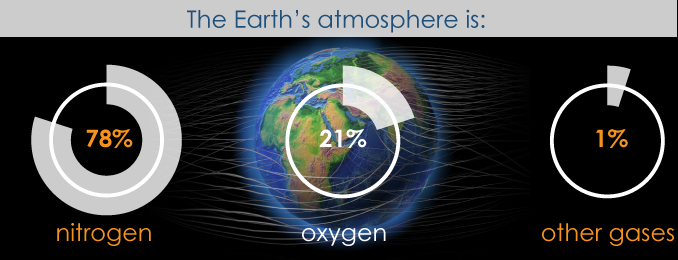

The Earth’s atmosphere is 78 percent nitrogen, 21 percent oxygen and one percent other gases, at a pressure of one atmosphere, which is about 14 lbs/in2.

Space vehicles carry liquid oxygen and liquid nitrogen in pressurized tanks that will rely on an air compressor to help regulate. Compressors can also help maintain the flow of these gases out of their tanks. They are combined at the proper rate and pressure using an internal cabin pressurization system.

In orbit, a space shuttle will only use a single oxygen-nitrogen system. However, during takeoff, both of the systems will be used to help keep everyone and all of the components on board operating at their peak.

Air that’s circulated through the space shuttle or space station will have a few elements that are common in air compressors and industrial air solutions — especially air cleaning systems that we often see combined with compressors used near wastewater applications. These elements include:

- Heat exchangers, which are common because of the extreme temperature fluctuations on space vehicles. They’re also the chief element used to pull water from the air, after which the air is recirculated and water moves into a waste container. In space, when you exhale, there’s water vapor that needs to be collected in order to avoid damaging equipment!

- Carbon dioxide canisters that remove carbon dioxide from the air. These operate by allowing the air to interact with lithium hydroxide. Compression systems can be used to move this air through the lithium hydroxide in emergency situations where air quality concerns exist or when certain parts of the shuttle or station are shut off for repairs.

- Filters and charcoal canisters that are used to remove odors and fine particulate matter, as well as to help clean up experiments. These are especially important when working with volatile chemicals and if you’re outgassing.

So What’s Next?

At the end of 2014, NASA adopted a new type of compressed air and gas canister that will provide breathable air for astronauts on the International Space Station.

The new system is a Nitrogen/Oxygen Recharge System, or NORS, with tanks that offer interchangeable use across the space station. Tanks and their fixtures are designed to work with the ISS’s existing air supply network, but also can be used in special, individual applications if needed.

Initially, the NORS tanks will be used to replace and refill existing air. By working with a top-notch air compressor, these new tanks can store air pressurized up to 6,000 pounds, which is more than twice the load of the prior set of tanks. That means a lot more air is available in each tank, reducing the number of times shuttles will need to bring air to resupply the ISS.

One surprising thing about how NASA is using compressed air in outer space is that these tanks become extremely hot when they’re filled in the Space Station Processing Facility at the Kennedy Space Center in Florida. They’re so hot, they need to be left on a stand for a full day in order to cool down after the pressurization.

“There’s really no other place in the world that operates up to 10,000 pounds per square inch like this in an operational environment,” says Steve Bigos, the leader of the NORS project at the Kennedy Space Center.

Air compressors in outer space often started with individual air units and rocket propulsion, but these new tanks help NASA and other space agencies expand into new methods. The new tanks will be used in the ISS’s ammonia-based cooling system as well as a variety of other experiments and repair systems.

Contact Us Learn More Find a Dealer Near You

Are You Space-Ready?

You might not be headed to outer space anytime soon, but we bet your operations can use compressed air to accomplish a lot of amazing things.

To learn more about the amazing things that compressed air and gas can do, visit our resources page here. We’ll help you figure out areas where you could be saving time and money with an air compressor, calculating the compressed air that you need and how to properly document the safety needed for running your air compressor.

Compressed air and gas create an amazing world, and Quincy Compressor wants to help you explore while making your business and your day-to-day operations better. When you’re ready to start seeing exactly what Quincy can do for you, visit our service locater page to find us and schedule a time for us to meet.