Compressed air, along with water, natural gas and electricity, are essential utilities needed in the manufacturing process. Its application is widespread in the automotive, plumbing, textile, agriculture, food and beverage, construction and other industries where moisture must be removed from the air within these compressors to perform efficiently.

This guide will cover everything you need to know about how air dryers work, how to remove moisture from an air compressor and the types of air dryers available.

What Is a Compressor Air Dryer?

Air dryers or compressed air dryers are machines that help mitigate the moisture levels in compressed air. An air dryer can absorb moisture and other minute impurities from the air, creating a healthier and safer work environment. In particularly humid environments, compressed air dryers ensure continued operations and prevent downtime.

Why Do We Need to Dry Air Before It Enters Compressors?

Moisture is always present in the air around us, and moisture levels fluctuate with the temperature. We measure moisture in pressure dew point (PDP), which refers to the temperature the air would have to be at to achieve the same dryness.

Condensation occurs in your air compressor during compression, which can impact the operation. Having excess moisture in your compressed air can damage your compressor machine, resulting in poor air quality and an inferior end product. This is especially important to prevent in larger factories during the manufacturing process where a multitude of pneumatic tools, motors and valves are necessary in the production line.

Why Is There Water in My Compressor?

Having the right type of compressor can ease the burden of excess condensation and moisture. The following are a few reasons you might have moisture buildup in your compressor:

- Undersized compressor: A compressor should be able to perform its intended function in relation to its size. Too small could strain the unit and the applied pressure may result in overheating. The pressurized air holds some of the moisture that is produced by the compressor due to overuse. Piston compressors are especially prone to this.

- Declining compressor: An older air compressor experiences wear and tear over time, leading to part degradation. This may cause increased moisture levels due to suppressed air, particularly if the machine is not maintained regularly. A failing compressor is ineffective in removing moisture from the air it takes in. You will notice signs of it declining by the prominent sounds it makes and it will also take longer to fill. An aged compressor’s parts also heat up faster and produce subpar compressed air quality.

- Humid work environments: High humidity levels have everything to do with how effective an air compressor is, regardless of its size or age. Maintaining the right humidity in certain States is hard because of the consistently hot temperatures experienced. This is why a cooling system should be used internally where the compressors are kept. Depending on the severity of the heat, some industries rely on the use of refrigerated air dryers to regulate the humidity while others prefer desiccant air dryers to absorb moisture caused by steam.

Methods for Drying Compressed Air

Although we are able to compress air, we cannot compress water. This is why specific methods were developed to dry compressed air. One involves bringing down the temperature of the air to reheat it. In its cooled-down state, moisture can be drained from the air after condensation occurs, leaving you with moisture-free reheated air.

In another method, a particular material is used to absorb moisture from the air, and then it is discharged from the compressor. An alternative, costlier method includes over-compressing the air, reducing the temperature, draining the condensates and them returning it to its normal pressure.

The Importance of Drying Compressed Air

Moisture trapped within an air compressor dryer can lead to complications that may have severe consequences for any industry. An example of this is when a pneumatic system used in the production line of an automotive company lacks the necessary devices to dry the moisture in compressors used to spray paint cars.

Air dryers were introduced to minimize the adverse effects and potential damage caused as a result. Some of the repercussions of excess moisture in compressed air include:

- Rusting: Production equipment may rust because of moisture that reduces the effects of greasing agents.

- Freezing: Surplus moisture can freeze in cold weather causing a buildup in control lines, leading to defective functioning.

- Poor paint quality: Where paint is applied, moisture can impact how it adheres to the material, the color composition and finishing once complete.

- Compromised controls: Pneumatic control systems are used across various industries to facilitate smooth operation. Any rusted or corroded parts may lead to the control ceasing functionality, which in turn could shut down an entire production line.

- Malfunctioning instruments: Production plants rely on instruments for accurate readings. Cold weather that causes moisture to freeze and disintegrate these instruments will affect their ability to continue operating.

Water Corrosion of Pneumatic Equipment

Pneumatic tools and controllers need the driest air content for efficient operation. Some consequences of water corrosion of pneumatic equipment include the following:

- The oil that builds up on pneumatic parts can contaminate the air it takes in, wearing down the cylinders. Seals and bearings may need regular replacement and production could ultimately stop if the issue persists.

- Vaporization absorbs the oils that lubricate the moving parts in an air cylinder. This will eventually lead to malfunctions and breakdowns.

- Vaporized air that passes to the spools, valves and pistons will harden and crack over time. In high-output production lines, a worn cylinder is useless.

- Transmitters, gauges and converters need clean, moisture-free air to operate. Even a drop of water or moisture seeping through any opening in these parts could impact its ability to work, which impacts the rest of the instruments connected to it.

- Moisture residue in airlines that supply these parts and instruments could lead to corrosion and malfunction.

The Impact of Vaporized Water on Products

In various power plants and their assembly lines, compressed air plays a vital role in preventing contamination of food and beverage containers. Here are a few examples of how vaporized water can impact goods and products in different industries:

- Food and beverages: Jars and bottles are cleaned and dried using compressed air. If it contains oil or water particles, it could introduce toxins into the assembly line. This may then lead to contamination of the contents within the containers, like food and beverages.

- Bakeries and supermarkets: Baking equipment that mixes ingredients can cause a disproportion in the ingredients and consistency if any moisture gets inside.

- Chemical products: Cleaning products and other chemical formulas could become tainted in factories where moisture or oil comes into contact with it during production.

- Textile industry: Knitting machine needles could stick if there are moisture or oil residue traces. Moisture-filled air blowers can also damage fabrics.

- Printing: The presence of moisture or oil in compressed air in the printing industry could lead to ink not sticking to paper surfaces, rendering the paper unusable.

- Test chambers: Here, air forms wind tunnels to replicate real-life high-altitude wind volumes. Condensation in the equipment must be avoided through vapor-free air.

How to Remove Water From an Air Compressor

Atmospheric air contains moisture that must be extracted manually. During the filtering and compression processes, moisture builds up naturally. This is normal and can not be prevented. The problem is too much moisture that accumulates which may eventually cause damage.

Depending on the application, you may use different methods to eliminate excess moisture from the compressed air in your compressor. Besides your compressor, the air in your surroundings contains moisture, which should also ideally be minimized.

Read the following on how to remove moisture from an air compressor:

Draining the Tank

Extremely hot air that exits the pump of an air compressor will contain vaporized water. This hot vapor will condensate internally within the tank, causing moisture formation. Draining the tank daily will help reduce the condensation and moisture buildup that occurs. It also prevents rust from building within your tank and keeps moisture out of your pneumatic tools.

Water Trap and Filter Regulator

Designed to work with incoming cool air, a water trap is a simple method of removing moisture from compressed air. The air enters one side and then it circulates around the bowl where the water collects at the bottom of the trap and drains out. The air will exit through a filter, which traps other impurities in the air.

A water trap is not generally used on its own, but as part of a multi-step system to remove as much moisture from the air as possible. It is especially used for applications that require extremely dry air, such as painting, sandblasting or powder coating.

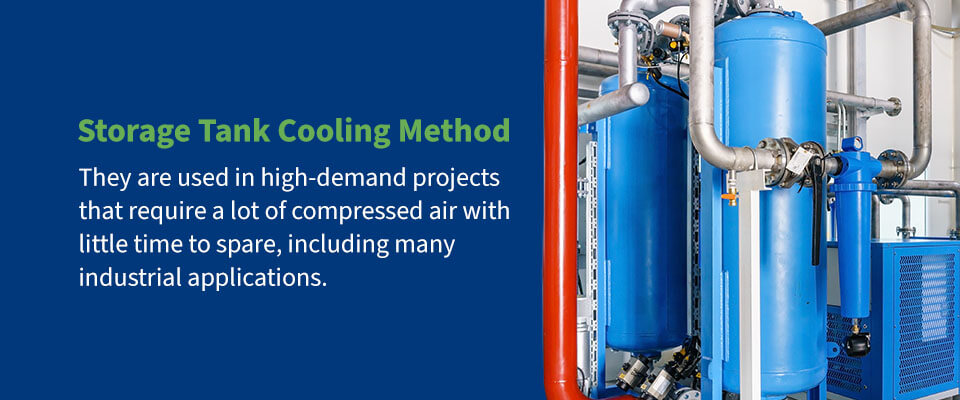

Storage Tank Cooling Method

Storage tanks, also known as air receiver tanks, act as temporary storage reservoirs to store compressed air as it exits the air compressor. They are used in high-demand projects that require a lot of compressed air with little time to spare, including many industrial applications. The air storage tank pressurizes the compressed air to keep it usable.

Receiver tanks can be used for either “wet storage” or “dry storage:”

- Wet storage: Wet storage is when compressed air is held post-compression, but before going through the air-drying process. This allows additional moisture to condense out of the compressed air before it ever reaches the air dryer, which greatly minimizes the amount of water in the final result.

- Dry storage: Dry storage is when the compressed air is stored in the receiver tank post-air drying, which protects the compressed air from gathering any additional moisture.

Absorption Drying

Absorption drying is a chemical process that uses absorptive materials — typically either water-soluble sodium chloride or sulfuric acid — to absorb excess moisture. This air compressor water removal method is not used as often as other drying methods but is still a viable option.

How to Keep Moisture Out of Your Air Compressor

There are a few things you can do to help keep moisture out of your air compressor. Some include:

- Investing in a larger compressor: Upgrade your air compressor to a larger one that can handle the capacity for the needed application, to avoid the pressure build-up that stimulates moisture formation in a small one that can not do the same job. Alternatively, make use of multiple smaller compressors.

- Using an effective air filtration system: Using an air filtration system that effectively separates moisture and pollutants from the compressed air is beneficial in keeping your compressor in optimal working condition. Filters should be inspected, cleaned and replaced regularly.

- Draining your compressor frequently: Your air compressor houses a draining unit that retains excess moisture and other contaminants. This should be emptied as often as possible to prevent rust, corrosion and moisture from accumulating.

- Arranging preventative maintenance inspections: Regular preventative maintenance will ensure your air compressor stays in optimal condition for as long as possible. This is because the technicians can stay on top of any potential issues that may arise before further damage is caused. They can proactively fix the problem without disrupting operations if something is wrong.

- Replacing excessively worn or damaged units: Your air compressor will eventually tire and lose effectiveness. This is especially concerning when surplus moisture can not be controlled despite attempts by maintenance technicians. Age and overuse may be good reasons for replacing your air compressor.

Types of Compressed Air Dryers

The solution to ensuring moisture does not detrimentally impact your business operations is adding an air dryer to your air compressor unit. They remove the extra moisture in the air that can lead to rust and other structural damage to your compressor’s internal parts, leaving only enough for the compressor to perform its task successfully. If this is not done, you could end up with poor air quality needed to execute a job and worse, damaged end products. Naturally, the knock-on effect will have serious implications for your business.

Here are the main types of air dryers along with brief descriptions and the advantages and disadvantages of each:

Refrigerated Air Dryers

These air dryers are similar to the refrigerators found in our homes and are also most commonly used. It is like a refrigerator because it uses a cooling process in the same way to prevent moisture buildup but the difference is what it is cooling. Household fridges keep fresh food and produce cool while the refrigerated dryer ensures the air in power plants is kept as clean and dry as possible.

Working similarly to an air conditioning unit, a refrigerated air dryer is connected to the air compressor and cools the air to a specified temperature, usually between 35-50 degrees Fahrenheit. This results in a pressure dew point of 33-39 degrees Fahrenheit. When the air reaches a temperature conducive to moisture saturation and condensation, it is known as the “dew point.”

The water drops out of the air and is separated, then the air is heated up and sent through the lines for its end-use. Some applications require a lower PDP, which would require a desiccant air dryer because the condensate will freeze at 32 degrees Fahrenheit and not be able to be removed. This is not one of the most economical ways to dry compressed air, but it is one of the most efficient and has a complete drying system in one unit.

These are a few of the advantages and disadvantages of refrigerant dryers:

- Less expensive to acquire and maintain than other air dryers

- Fewer maintenance costs

- Resistance to oil pollutants in the air

One major drawback is that they can not be used for sub-freezing temperatures due to the damage the frozen air can cause to your dryer.

- Non-cycling refrigerant dryers: In a non-cycling refrigerated dryer, the refrigerant perpetually circulates within the machine. This allows for quick responses to changes in the load, be it low or high densities of moisture within the incoming air. As such, factory environments with steamy engines can be de-moisturized in much the same way as low-moisture environments. The flow of the refrigerant is regulated with a bypass or unloader valve. In most units, the refrigerant is condensed by a heat exchanger after the compression process has completed a cycle.

- Cycling refrigerant dryers: Refrigerant dryers of the cycling variety use refrigerant to cool down a glycol or aluminum mass, which surrounds the air passage. The compressed air is then cooled by a thermostat-controlled heat sink. Unlike a non-cycling refrigerant dryer, a cycling system works to conserve energy during periods of low airflow. The dew point, however, is variable. Cycling refrigerant dryers are also a high overhead cost, partly due to their size and weight.

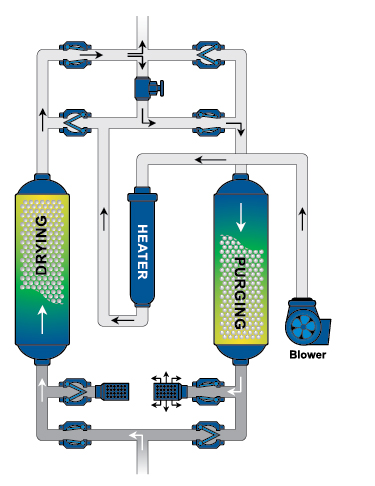

Desiccant Dryers

When air compressors intake air to compress, that air gets warmer as compression levels reach 100 pounds per square inch (psi) or higher. As the stream of compressed air cools, it creates vapor and moisture. Desiccant air dryers are one method of combating this moisture by adsorbing and reversing the cycle for applications requiring very dry or sterile air.

Desiccant dryers rely on desiccants, a dry material — typically available as a powder or small beads or pellets — covered in surface pores that attract and remove water through a process called physisorption. The air goes through the center of the pressure vessel, removing water as it circulates. Once the specified moisture content is reached, the air is moved out of the dryer to the lines for its end-use. A high-efficiency coalescing prefilter is needed to prevent damage from water and oil sludge.

Desiccant dryers are commonly used in the following applications:

- Material processing: Any given material has its own processing requirements, which need to be met without deviation for things to materialize as planned. Desiccant air dryers help make this possible.

- Mold prevention: When left to evaporate into surfaces the moisture turns to mold, which reduces sanitation in any working environment. With a compressed-air drying system in place, factories are spared of mold.

- Medical: Dry, sterile compressed air is critical for many medical applications, including in hospitals, emergency rooms, intensive care units and dental offices. Air for medical use has to be reliable and clean, especially when used for ventilation systems that deliver oxygen to high-risk patients with critical conditions, like those undergoing surgery or patients that can’t breathe on their own.

- Commercial artistry: Commercial air applications, such as vehicle paint detailing and woodworking, play a large part in what a final product looks like, which is why operators need air free from bacteria and rust contaminants.

- Food and beverage: Food and beverage manufacturing and distribution centers need sterile, dry air to keep all items fresh and within safe temperature levels for sale and consumption.

- Manufacturing: Manufacturing facilities use dry compressed air for machine equipment and maintenance, and any unwanted moisture could damage high-performing systems and wear components down.

- Pharmaceutical: Pharmaceutical developers work with highly sensitive materials, and even minuscule inconsistencies or contaminants can render entire batches unsafe for use.

- Creative projects: Many crafters and artists need dry, clean air to complete their projects, especially those with high levels of detail or made with delicate materials.

- Agriculture: Residential and commercial farms often use compressed air to spray crops for cleaning or processing, and excess moisture or bacterial contaminants could cause additional harm or render crops unusable.

A few benefits and drawbacks of desiccant dryers are listed below:

- They have low dew points and are therefore more suitable for low-temperature environments.

- Operating costs are fair although the initial acquisition cost is high.

- They can be used remotely and in volatile environments.

- Oil pollutants can deteriorate the desiccant agent.

- Desiccant dryers often need purged air.

Despite their mechanical differences, refrigerant dryers and desiccant dryers have more similarities than differences because both serve the purpose of ridding nearby ambient air of moisture. Therefore, the debate between the two dryer types is not so much about which is better, but which is better suited to the needs of a given environment. In some cases, refrigerant and desiccant dryer systems work best in combination with each other, because one dryer’s strengths compensate for the other’s weaknesses, and vice versa.

Quincy Compressor manufactures a full line of desiccant air dryer systems with dual towers that allow for purging — regeneration of the desiccant — in one tower while the other tower dries compressed air. This feature provides customers with longer use of the desiccant and continuous operation for extended periods, as is common in industrial environments.

Chemical Air Dryers

Chemical air dryers use special chemicals like sodium and lithium that absorb the excess moisture of the compressed air, after which they are discarded together. Using an effective air filtration system with this dryer type is vital to avoid chemical build-up that could damage the dryer. A few benefits include:

- Reasonable acquisition cost

- No moving parts of the machine to consider

- Easy to operate

There are also a few disadvantages to consider, like the fact that it is expensive and extensive to replenish chemicals, which are also not easy to dispose of. The best quality air filtration system can be costly but is more effective with this dryer.

Membrane Air Dryers

These dryers remove dampness during food production by separating compressed air from gas using semi-porous membranes to filter through. They are energy-efficient since they do not require electricity and operate quietly. They are also more affordable than the other air dryers but constantly need cleaning and removing oil pollutants.

Deliquescent Air Dryers

Deliquescent air compressor dryers have a single tank and also use a desiccant, but they can only provide a PDP of 20-25 degrees Fahrenheit lower than the air temperature entering the dryer. When the compressed air enters the tank, it reacts with the desiccant material to produce a liquid effluent that needs to be drained out of the dryer and disposed of according to hazardous waste regulations.

These types of dryers are not used in industrial applications because the dried compressed air can contain small particles of the affluent, which would be corrosive to equipment down the line.

Piping System Air Dryers

You can plumb your airlines to remove water from your compressed air. By using long lengths of metal piping built into two or more up-and-down patterns, the air is cooled as the piping absorbs the heat. Reacting to gravity, the water drops down to the bottom of the piping system into a ‘drip leg’ or ‘drop leg’ and is trapped by a water trap, a T-fitting and a ball valve.

The air continues on its path in the up-and-down piping, releasing more moisture through each segment. Each drip leg will have less water. By the time the air moves through the last segment, there should be no water in the drip leg. This can be used as a stand-alone method of drying compressed air and is the most common and cost-efficient way to dry compressed air in a shop for business or personal use.

Air Dryer Tips

Having an air dryer is a great step toward improving the quality and efficiency of your compressed air. To get the most out of your investment, follow these additional air dryer tips:

- Improve the quality of your intake air: The less polluted your intake air, the less your air compressor and air dryer will have to work to purify it. Contaminants can be liquid, solid or gas, and can enter the air before it’s processed by the machine, or inside the machine itself. There are two steps to minimize this contamination — promoting a clean workspace and introducing a filtration system to your compressed air cycle. If your industry requires heavily regulated air, you might also consider a lubrication-free compression system.

- Use a compressed air storage system: Use a compressed air storage tank to store dried, filtered air once it has been compressed. This will help prevent additional moisture from re-entering the air, saving you time, energy and valuable resources.

- Schedule preventive maintenance for your air compressor: An efficient air drying system means little if your compressed air machine is not working correctly. Schedule regular preventive maintenance checkups for your compressor and air dryer systems to avoid production setbacks. You should also create and implement a monitoring system that allows you to stay up-to-date on the status of your equipment and the quality of the air being produced. Taking preventive measures like these can alert you to possible concerns and have them adjusted before they turn into costly, more time-consuming repairs later.

Quincy Compressor Is Your Air Dryer Solution

Whatever your air dryer needs, Quincy Compressor has dryers for every application. We are confident in the high quality of our products that will deliver the best air treatment management for your specific requirements.

When you’re ready for us to come out for a service or you need an air dryer upgrade, call (251) 937-5900 or request a quote and we’ll contact you.

Recommended Products

Refridgerated Dryers

View All

Desiccant Dryers

View All

QHD Heatless Desiccant Dryer

The QHD has been engineered to ensure optimal performance and efficiency in a range of different applications while keeping downtime to a minimum

Learn More

QHP Heated Purge Desiccant Dryer

The QHP series of heated desiccant dryers features a built-in heating system that regenerates the offline tower using half the amount of air as our heatless products

Learn More

QBP Blower Purge Desiccant Dryer

These dryers combine heat with forced ambient air for regeneration

Learn More

QMOD Heatless Modular Desiccant Dryer

These compact dryers use a small portion of dried compressed air to regenerate the offline tower

Learn More