It’s impossible to understate the importance of having the right tools for the job. Nail guns are one of those versatile tools that can do so many different jobs on one worksite that they can cut down on the amount of other equipment you may need.

Nail guns shoot nails or heavy-duty staples into your target object, eliminating the need to manually hammer nails into a surface. This swap can save your operation valuable time and money by reducing the risk of errors and minimizing the amount of time needed to attach different materials.

The key to finding the right components is to match your air compressor unit to the specific requirements of the job at hand, rather than the other way around. This guide explains how to identify the right compressor for your equipment and needs so you can maximize efficiency and return on investment.

Understanding Nail Guns and Their Requirements

Pneumatic nail guns use blasts of concentrated air to push nails through walls, roofs and other solid surfaces. There are various types of nailers specifically designed to handle different types of projects across sectors. They’re most commonly used in the following industries:

- Construction

- Woodworking

- Renovation

- Furniture manufacturing

- Packaging

They’re also commonly used in DIY home improvement projects, such as deck building and trim installations. The specific requirements for each nailer depend on the job, the nail gun type and the task at hand.

What Air Compressor Sizes Are Available for Nail Guns?

There are many different air compressor sizes for various applications, though nail gun air compressors tend to be small and portable.

For most nail gun applications, air compressors rated between 2.0 cubic feet per minute (CFM) and 4.0 CFM are suitable. These compressors are lightweight and capable of handling various tasks, including installing roofing, stapling upholstery and more.

If you’re unsure what models are available for your application, it can help to speak to an experienced sales rep who can walk you through their offerings.

Best Air Compressors for Each Nailer Type

When you’re selecting an air compressor for a pneumatic nail gun, you need to consider several factors:

- Portability: Most nail gun applications require you to move around the jobsite with ease, so selecting a lightweight and compact model is essential. While stationary models work well for industrial applications, they’re heavy and provide a higher volume of air than you’ll likely need.

- Noise: Some types of compressors, like reciprocating piston compressors, are louder than others. Depending on your application, you’ll want to consider how much noise you and the surrounding environment can tolerate before selecting a model.

- Capacity: Check your nail gun’s specifications to determine the maximum air pressure and airflow it can handle. These measurements will be in pounds per square inch (PSI) and CFM.

- Power type: You can choose between electric, cordless and gas-powered compressors to power your application. While gas-powered compressors are more portable than electric models, they’re much louder and less suitable for use in areas where noise is a concern. Cordless air compressors are compact and use rechargeable batteries, making them suitable for working in tight spaces that require additional flexibility.

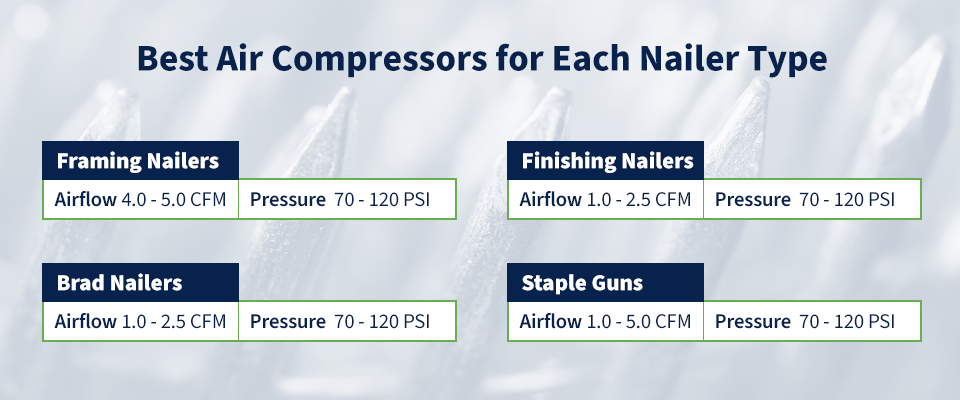

Here, we break down the best air compressor models by nailer type to help you match your equipment to your needs.

Framing Nailers

Framing nailers typically handle heavier loads than other nail gun types, which is why they require larger compressor sizes. A compressor with an airflow of 4.0 to 5.0 CFM and a pressure rating of 70 to 120 PSI is often sufficient.

This compressor size will deliver enough power to the nailer to:

- Connect large pieces of lumber for framing or wall-building.

- Install fences.

- Build decks and wood patios.

Framing nailers are common in industries like construction due to their high capacity for conveying intense bursts of air and securing nails and pins in challenging materials.

Finishing Nailers

While finishing nail guns are similar to framing nailers, they require smaller air compressors. A compressor offering airflow of 1.0 to 2.5 CFM and air pressure of 70 to 120 PSI usually suffices for applications like securing trim and molding to the exterior of your home. They’re best for DIY renovations, such as flooring installations, cabinetry assembly and more.

Brad Nailers

For brad nailers, you’ll need a slightly smaller compressor than you would for a finishing nailer. Airflow should be between 1.0 and 2.0 CFM, and air pressure should remain between 70 and 120 PSI.

Brad nailers are most commonly used to drive small, thin nails known as “brads” into objects for several purposes:

- Temporary construction of a structure

- Securing thin trim or molding

- Cleanly finishing woodworking projects

Staple Guns

Pneumatic staplers should provide a consistent airflow of 1.0 to 5.0 CFM and air pressure of 70 to 120 PSI. These nail guns are typically used for applications such as:

- Securing insulation.

- Reupholstering furniture.

- Fastening large packages.

- Assembling product components.

- Installing flooring underlayment.

Why Is It Important to Use the Right Size Air Compressor for a Nail Gun?

Paying attention to the specs of your air compressor is critical for ensuring you have the proper tools for efficient and effective work.

Choose an air compressor with a lower airflow than you need, and you may not produce the force you need to secure an object in place. Using an air compressor that has a capacity higher than your nail gun can handle can damage the tool and render it ineffective, potentially sinking your investment and requiring you to purchase a replacement nailer.

If you discuss your needs with an experienced sales rep, they can help you identify the right model for your specific nail gun and application.

Find the Right Air Compressor for Your Nail Gun at Quincy Compressor

If you need a portable air compressor for your next nail gun project, Quincy Compressor has what you need. We offer various energy-efficient compressors and components for a wide range of nail gun applications, including construction projects, home renovations and much more.

Whether you need help deciding on the best air compressor for your framing nailer or you know exactly which product you need for a brad nail gun, our team can help you find products that meet your requirements. We also offer a full range of compressor parts and maintenance services, so you can stay productive as your compressor ages.

Browse our online product lineup to see specs for our air compressors, and contact your nearest dealer to learn more about our selection.