When air compressors fail, they can cost you money or damage products. That is nerve wracking, but shouldn’t scare you away from buying a used air compressor, especially when you can work with a reputable dealer. The first recommendation is to buy a new unit, but if budget is a concern, a used machine could offer a temporary solution.

Air compressors are used in tire shops, on manufacturing lines, by sports equipment dealers and more. They have a wide range of uses many offer plenty of options to meet your specific demands.

Air compressors are good stellar pieces of used machinery because many can function for years. Plus, purchasing used equipment means money. Many used machines that have been properly cared for by the previous owners can make a good temporary fix until you can buy a new one. Before you decide to jump into that used air compressor purchase, however, there are some things you should know.

This guide will look at the chief elements of your standard air compressor selection with helpful hints along the way about how to ask for the specific used model you’re considering. Every application is unique, so always ask questions until you feel comfortable, because you want to get the right fit.

Elements to Consider When Buying a Used Air Compressor

When you use pneumatic tools regularly or have a line that requires multiple power tools, you’re ready for a professional air compressor. The next step is for you to pick the type of air compressor that you need. This guide will look at each type and give you some tips on what to watch out for when buying a used version of that air compressor.

Please note that oil-lubricated air compressors are typically recommended for industrial and larger-scale applications because they have a stronger engine and higher CFM ratings, plus many will have options for twin tanks or a single large tank.

Always thoroughly inspect the entire compressor, especially the tank, because wear may differ between the owner’s application and yours. Also have the unit inspected by your local dealer for any sings of trouble.

Paying a little more for a stronger air compressor can definitely be worth it, even if you’re achieving some savings by buying a used air compressor. Let’s look at a few of your options. Remember, not everything here is mutually exclusive, so the compressor you’re looking at may fall into a few of the categories below.

Electric

The basic electric air compressor typically uses your standard household voltage ratings between 110 and 120 volts. If you’re looking at a model that has a 2HP engine, it’ll require a 220 to 240-volt outlet. This is your air compressor of choice for indoor use because it doesn’t have gas and thus, there’s no exhaust released.

One thing you’ll want to check is how and where the used electric air compressor was used. If it was powered through an improper setup, you might see engine problems sooner than usual.

Gas-Powered

The best air compressor for your outdoor job is typically a gas-powered compressor. It has a standard power source and is often able to carry a more powerful engine than an electric model of the same size. Gas air compressors need good ventilation and will often use oil as part of their cooling mechanism.

Gas-powered compressors come in a wide range of sizes, shapes and tank capacities. Match your compressor to your job site by looking for options with larger storage tanks, wheels, handles, rubber feet and multi-valve configurations.

The used gas powered air compressor you’re considering purchasing likely had a rough life. These tend to get hauled around and attached to tools across the spectrum. They can also be perfect for a variety of dirty, grimy tasks.

You’ll want to check the filters, tanks and hoses for signs of unusual wear. We’ve also heard tales about used gas-powered compressors coming with bad pressure regulators, so a test drive isn’t out of the question.

Fixed/Stationary

Stand-up compressors tend to be stationary and are installed in workshops and garages. These are your go-to for heavy-duty, commercial uses. If you’re working with your air compressor consistently and have multiple tools that you’ll need powered, a stationary compressor is a safe bet.

When purchasing a used stationary or fixed air compressor, always ask to see where it was previously installed if possible. You’ll want to check if there was enough space around the compressor for it to properly exhaust and not trap heat. If the space looks too tight or you see a lot of black, greasy residue, you might be looking at a compressor with internal components that were put under more stress than usual.

The exhaust and filters should also be free from most dust and dirt. If they’re not, this could mean that the compressor was not cleaned often enough or didn’t have good circulation.

Single-Stage or Two-Stage

Stages denote how many pistons an air compressor has that will compress and transfer air to your tank. Single-stage options are usually cheaper and less effective for high-pressure situations, so they tend to be used for applications requiring less than 120 PSI.

The two-stage option compresses your air significantly more and is your best bet for an industrial application. They work well in continuous situations and can reach levels at or slightly above 150 PSI.

Asking about these models’ use patterns can let you know if they’ve been managed properly or are being run too hard. Hours of operation are a good indicator of wear and tear.

Other Elements to Consider When Buying a Used Air Compressor

Part of deciding what to look for when purchasing a used air compressor is the way you plan to use your air compressor. From lugging it around to different jobs to installing it on your shop floor, to a tank size that’s perfect for 20 tools versus a tank for just one, you’ve got a lot of questions to ask yourself.

Here are just a few of the questions we think you’d do well to consider when you want to buy a used air compressor. Compromising on these may mean you won’t save your money in the long run because you’ll either have to buy a new one anyway or buy multiple units to accomplish everything that you need.

Where Does My Compressor Need to Go?

Most industrial-grade air compressors aren’t easily portable. They can be tough to carry, especially if they’re not designed to be constantly moved. Going with a used option that doesn’t have a handle and wheels can give you a lot of back-breaking work whenever you need it to go with you.

On the other hand, wheels and handles don’t make a lot of sense for a compressor you want to install in a fixed position. They can easily be moved on accident, causing them to roll away from your power source. Your staff may even move them on purpose, not realizing they’re mean to be fixed, when they need a little extra space.

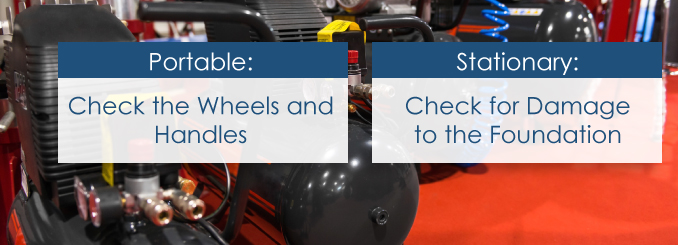

When buying a portable compressor, always check to make sure there’s no problem with the wheels or handle. For stationary models, you’ll want to double-check that there’s no breaking or damage to its foundation, whether that’s metal, rubber or a specific plate.

The other location consideration is indoors or out.

Electric air compressors are the most convenient if you have access to a power source. They won’t run out of juice halfway through the job, they can be mounted or portable, and they don’t mind working in the sun or sitting inside all day.

Gas-powered air compressors give you the freedom to go and work where you need in most cases. They won’t work for indoor jobs because of their exhaust, but you’ll be able to take them with you to any outdoor site where you work today or in the future. If there’s a chance that you won’t have an outlet, gas is the way to go — just be sure you bring a little extra fuel.

We’ve already touched on what to ask about for these models, but always be sure to look at maintenance records and check for leaks when you’re considering a used air compressor.

How Much Compressed Air Do I Need?

Larger tanks tend to give you more compressed air at a higher pressure and allow your air compressor enough time to kick on and create more so you don’t run out. They’re more expensive and harder to maneuver, but they’ll be more efficient and better for your team if you have high PSI demands.

You’ll often see larger tanks used for equipment like pneumatic tools because they deliver consistent, short bursts of pressurized air. This allows the motor a moment to catch up and return the whole tank to that higher PSI.

Smaller tanks typically aren’t able to deliver a compression level as high as larger tanks, but they are often paired with motors powerful enough to deliver a steady stream of lightly pressurized air. This makes them perfect for assembly lines and production that move rapidly. You’ll also see them in light jobs with mixed use because they’re able to quickly compress the air and are easy to move around.

Ask your potential seller about how these were used. If they have a compressor used for the wrong task, there may be undue strain on the engine or it could prematurely face problems with hoses and connection points.

Is Noise an Issue?

Certain air compressors can be extremely loud, so noise levels are something to consider. Oil-lubricated air compressors are generally more quiet. The lubrication keeps elements running smoothly and this helps to reduce the noise. Oil-free air compressors don’t have internal lubrication so they tend to be noisy and rattle about a lot more, which can sometimes cause them to need replacement sooner.

Oil-lubricated compressors offer a few other points to consider. They tend to last longer but they’ll require a consistent maintenance schedule to work properly. You also will likely need to mount these because they require a flat surface to operate properly. Lubricated models work well when you have continuous demand, but they will mist oil eventually — a major problem for sensitive manufacturing — and you can expect small spills often when changing the oil.

You’ll need a trusted source for an oil-lubricated unit because it needs to have been properly maintained. A used, lubricated air compressor that isn’t properly cared for can quickly turn into a lemon.

Although louder, oil-free compressors have a unique set of benefits. They tend to be more versatile and mobile, not requiring a flat surface. Their internal parts will wear out a little sooner due to general use, but they don’t require consistent maintenance because you don’t have to constantly change and replace any oil. They’re a solid choice for periodic use.

Make sure you get an accurate record from the previous owner to see the age and use pattern, so you can know when to reasonably expect to replace or repair the unit.

How Strong Should I Go?

Take the air compressor horsepower you see listed in an advertisement with a grain of salt. Many engines have their HP inflated and the spec can be misleading. The horsepower is standard to engines and you’re typically not going to look above 1 or 2HP for most applications, though some industrial settings will need to seek out a true horsepower of 5HP or more.

The best strength for an air compressor is often the volume of air it can deliver at a specific pressure. In many cases, the relationship is inverse — meaning that as the volume increases, the max pressure decreases and vice versa. This is measured by looking at the compressed air delivered in cubic feet per minute (CFM) and comparing to the discharge PSI.

When you want to judge an industry standard, you can look for the Standard Cubic Feet per Minute (SCFM) which is the CFM taken at sea level, at 35 percent relative humidity and at 68 degrees. Learning the SCFM will give you the best shot at determining whether or not the compressor you’re looking at can deliver the proper CFM required by your tools.

Just for your information, standard expert advice is to overestimate the power you need by as much as 40 percent. That means you want a CFM well above and beyond your top tool’s requirement so you can properly work as the compressor ages.

In 2004, a class-action lawsuit was settled and air compressor manufacturers in the U.S. were no longer allowed to advertise HP based on “peak” or “max” power. They must advertise using the continuous power output of the electric motor shaft or continuous power input to the compressor shaft. That means the box will be a lot more honest, but your seller may still use the older numbers to give themselves a boost.

Ask about both the device’s HP and CFM, and then check with the specs that the manufacturer provides. Not only will this help you determine if it’s the right air compressor, but you’ll have a good way to judge the honesty of the potential seller of your used air compressor.

Should I Buy a Used Air Compressor?

Buying a used air compressor can be a great way to save a significant amount of money and give your operation exactly what it needs until a new unit can be installed. Your main concern when buying used is working with a reputable person, shop or company who knows about air compressors and has maintained the equipment properly.

Quincy Compressor has been trusted in the market for nearly a century, and we recommend that you look for a provider with a reputation like ours. We know there are a lot of questions about what to look for when purchasing a used air compressor, so we’re here to help.

You can use our service locator to find a local representative to get your questions answered and learn about the perfect air compressor for your needs. Even if we don’t have it, we’ll assist you in building a profile so you know what to look for when you do find a compressor to buy.