Cómo mejorar la eficiencia energética de un sistema de aire comprimido

El aire comprimido es fundamental en muchas aplicaciones industriales y no industriales, desde la alimentación de herramientas neumáticas y sistemas de transportes hasta la limpieza de equipos y el relleno de objetos de parques de atracciones. Aunque el aire presurizado es una fuente indispensable de energía, los sistemas de aire comprimido son algunas de las máquinas que consumen más energía.

Mejorar la eficiencia de un sistema de aire comprimido puede tener un impacto positivo en los resultados de una empresa. Esta guía de Quincy Compressor explora consejos prácticos para aumentar la eficiencia energética de los sistemas de aire comprimido y reducir los costes operativos.

1. Comprender el sistema existente

El primer paso para reducir el desperdicio de energía y mejorar la eficiencia de tu sistema de aire comprimido es realizar una auditoría exhaustiva de tu sistema actual. Un análisis profesional del compresor te ayudará a identificar áreas de mejora, permitiéndote crear una estrategia para ahorrar costes. Normalmente, una auditoría profesional de sistemas implica:

- Análisis de rendimiento: Es una evaluación de cómo funciona la máquina, incluyendo las horas estándar de funcionamiento, el consumo energético, los niveles de presión y la salida de aire. Realizar análisis de rendimiento y registrar datos durante un periodo específico permite al técnico observar cómo se comporta el sistema bajo diferentes condiciones.

- Aplicaciones existentes: Un recorrido de toda la instalación proporciona datos sobre los distintos procesos que requieren aire comprimido. Contar con datos detallados sobre casos de uso es clave para identificar desperdicios y usos inapropiados.

- Identificación de desafíos: Una vez que un profesional recopila los datos necesarios, los analiza para obtener información sobre los problemas e identificar patrones de ineficiencia. Estos varían, desde inconsistencias entre el suministro y la demanda de aire hasta el drenaje de energía fuera del horario de producción.

Analizar tu sistema actual e identificar sus desafíos es necesario si quieres priorizar soluciones basadas en el impacto.

2. Optimizar la caída de presión

Es difícil evitar una caída de presión en un sistema de aire comprimido, ya que para ello se requiere que el compresor funcione a una presión más alta. Sin embargo, cuanto mayor es la presión de descarga del compresor, más energía consume. Si aumentas la presión de funcionamiento en 2 libras por manómetro de pulgada cuadrada, el consumo de energía de la máquina aumenta un 1%.

Por lo tanto, optimizar el sistema para la eficiencia consiste en minimizar la caída de presión a no más del 10% entre la descarga del compresor y el punto de uso. Más de esto significa que tu sistema consume energía en exceso.

Existen diferentes factores responsables de la cantidad de caída de presión en los sistemas de aire comprimido, como el diámetro de la tubería, la textura de la superficie, las conexiones y válvulas, la velocidad del aire y el equipo de tratamiento del aire. Estos factores pueden reducir significativamente el consumo de aire y provocar caídas de presión elevadas en el sistema.

Una evaluación del sistema de aire proporcionará datos valiosos para ayudarte a mantener una caída mínima de presión y mejorar la eficiencia.

3. Eliminar las fuentes de fugas

Las fugas que pasan desapercibidas en los sistemas de aire comprimido pueden provocar pérdidas significativas debido al desperdicio de energía y a la reducción de la productividad. Por ejemplo, una auditoría del sistema de Mikron Industries encontró fugas en aproximadamente dos tercios de la instalación, que se estimó costaron a la empresa 157.000 dólares anuales.

Los sistemas de distribución de aire comprimido necesitan una red de tuberías actualizada que elimine los problemas de fugas comunes en sistemas de tuberías obsoletos. Los avances actuales en la industria han llevado a sistemas de tuberías fabricados con materiales fiables y accesorios que ofrecen una baja caída de presión y permiten modificaciones para abordar las fuentes de fugas.

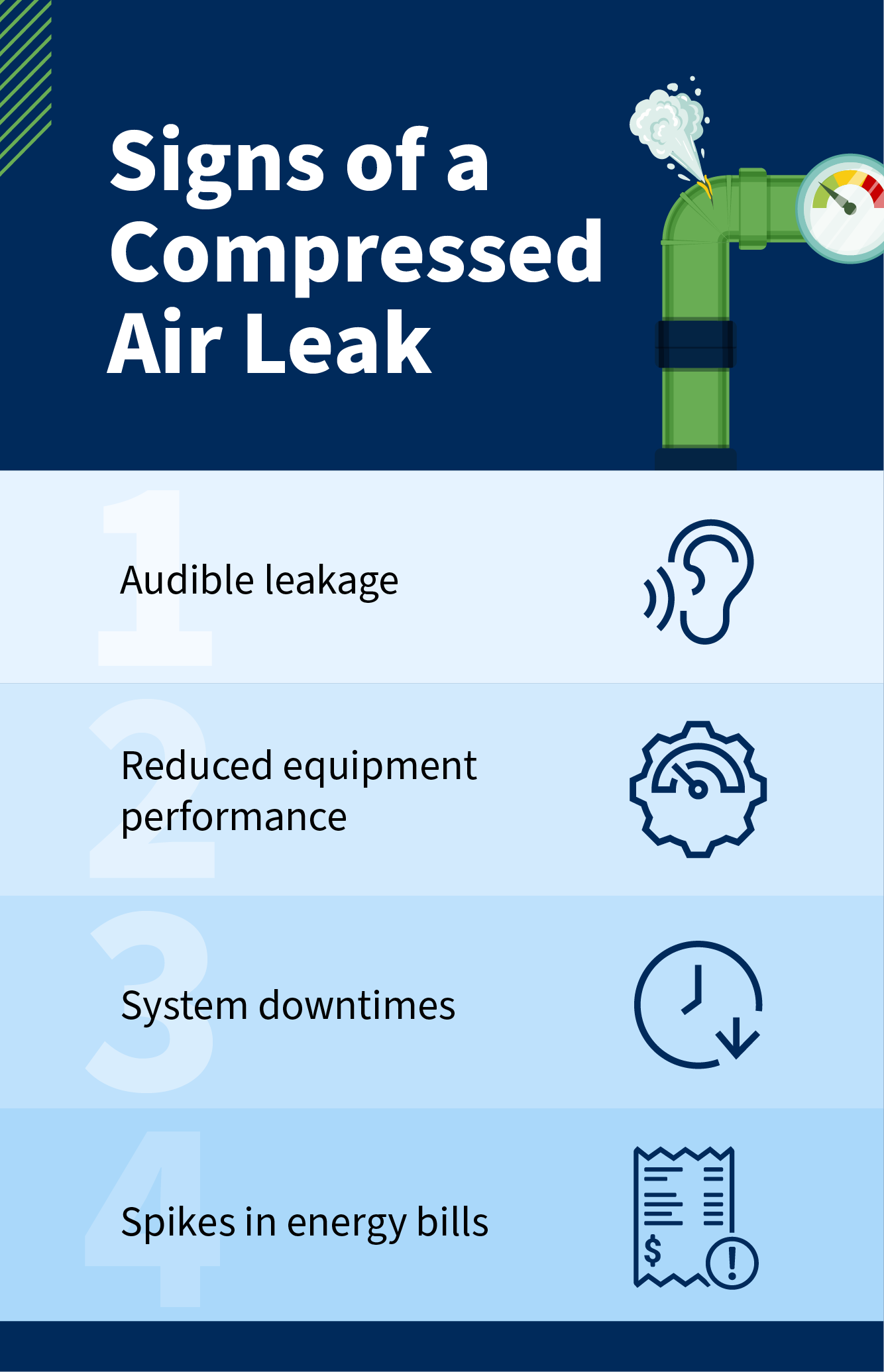

Identificación de una fuga de aire comprimido

Las fugas de aire comprimido pueden ser un desperdicio silencioso de energía en instalaciones comerciales e industriales. ¿Cómo sabes que tu sistema tiene fugas de aire? Aquí tienes señales clave a las que debes estar atento:

- Fuga audible: Debido a la alta presión del aire que escapa, los silbidos o silbidos son comunes en los sistemas de aire comprimido con fugas. Sin embargo, algunas fugas son inaudibles y, por tanto, más difíciles de detectar.

- Rendimiento reducido del equipo: Los compresores con fugas son ineficientes y probablemente funcionarán mal, resultando en baja potencia.

- Inactividad del sistema: Las paradas frecuentes del compresor pueden deberse a fugas no identificadas. Como la máquina trabaja más para compensar la pérdida constante de presión, sufre desgaste y se avería con más frecuencia.

- Picos en las facturas de energía: Una fuga de aire que no se percibe aumenta significativamente los costes energéticos. Esto se debe a que el sistema utiliza más energía para compensar el aire perdido y alcanzar la salida requerida.

Recuerda que las fugas de aire comprimido pueden pasar desapercibidas fácilmente. Puede que no identifiques ninguno de los signos anteriores sin una auditoría profesional, especialmente si tienes una operación grande. Algunas filtraciones son inaudibles. También puedes atribuir picos en el consumo energético o el bajo rendimiento del equipo a otros problemas existentes. Lo mejor es programar una auditoría energética a nivel de sistema para obtener una imagen más precisa.

4. Elegir el compresor adecuado

Una forma eficaz de garantizar la eficiencia energética de un compresor desde el principio es instalar el sistema de aire comprimido adecuado para tu instalación. Aquí tienes algunas consideraciones para seleccionar el compresor adecuado que mantenga la eficiencia:

- Tecnología de accionamiento de velocidad variable (VSD): La tecnología VSD permite a las máquinas industriales equipadas con ella ajustar la velocidad del motor según las demandas de una aplicación específica. Elegir compresores con VSD es ideal para aplicaciones que requieren demanda dinámica de aire: la máquina consume solo la energía necesaria.

- Compresores centrífugos: Estos compresores de alta resistencia utilizan un proceso de compresión dinámica que los hace eficientes para demandas de aire a gran escala. Los compresores centrífugos modernos cuentan con impulsores avanzados diseñados para satisfacer los requisitos de flujo de aire y presión.

- Requisitos de tamaño: El ajuste adecuado es fundamental al seleccionar sistemas de aire comprimido. Las opciones sobredimensionadas desperdician energía, mientras que las opciones pequeñas luchan por satisfacer la demanda y soportar las fluctuaciones de presión. Debes elegir un tamaño de compresor que se ajuste a tus necesidades para mejorar la eficiencia.

- Compresores sin aceite y con inundación de aceite: La elección entre compresores de aire sin aceite y sus alternativas inundadas depende de tus necesidades. Dicho esto, las alternativas sin aceite suelen tener menos fugas y consumo energético.

5. Optimizar los controles del compresor

Los sistemas de control de compresores desempeñan un papel fundamental en la eficiencia energética, especialmente en sistemas con múltiples compresores que requieren una solución de control más compleja. Los controles del compresor determinan cuándo funcionan los sistemas, así que con varios compresores es necesario determinar qué unidad funciona y cuándo usar la automatización.

¿Cómo ayuda optimizar los controles del compresor a mejorar la eficiencia energética? Aquí tienes una visión general del control de secuencias y el control central optimizado, y cómo funciona cada uno.

Control de secuencia

Un sistema de control de secuencia de arranque puede programarse para reaccionar a caídas de presión del sistema, donde un compresor adicional apaga la carga en funcionamiento si la presión disminuye. Dado que la secuencia sigue siendo la misma, incluso con el uso de unidades alimentadas por VSD, los volúmenes de presión siempre serán mayores de lo necesario, lo que conduce a facturas de energía elevadas.

Controles centrales optimizados

Con controladores centrales optimizados, el sistema intuitivo es capaz de conectar todos los compresores, reduciendo la banda de presión y optimizando el rendimiento para la eficiencia energética. Cuando la presión cae, un controlador de secuencia simplemente selecciona la siguiente unidad independientemente de su capacidad. Un controlador optimizado elige la combinación ideal de compresores para satisfacer eficientemente la demanda de aire requerida. En caso de una caída significativa de presión, selecciona la unidad con mayor capacidad para compensar.

6. Implementar la recuperación de calor

Implementar la recuperación de calor no reduce necesariamente el consumo energético de tu compresor, pero sí mejora la eficiencia general de tu sistema. Hasta el 90% de la energía eléctrica que consume un sistema de aire comprimido nunca se utiliza y se convierte en calor.

Recuperar el calor generado por los compresores de aire elimina el exceso de desperdicio, ya que puedes reutilizar el calor para reducir costes en otras áreas de la instalación. Por ejemplo, puedes utilizar el calor recuperado para cubrir otras actividades que requieren mucha energía como:

- Calefacción de espacios: Calentar una o más zonas de una instalación, especialmente en invierno, ya requiere mucha energía. La calefacción de espacio es un uso ideal para el calor residual recuperado.

- Calentamiento de agua: El agua calentada es necesaria en muchas aplicaciones industriales. En lugar de drenar la electricidad para calentar agua, puedes reutilizar el calor residual de tu compresor para este propósito.

- Aplicaciones específicas de calor: El calor por aire comprimido recuperado es una solución eficaz para alimentar operaciones específicas de calor ya habituales en muchas industrias. Estos procesos incluyen limpieza, refinado, secado, fundido y más.

7. Optimizar el uso final

Los sistemas de aire comprimido más eficientes siguen sin ser eficientes energéticamente si hay un problema en el uso final que provoca pérdida de aire. Aquí tienes algunos de los pasos a seguir para optimizar las soluciones de uso final:

- Utiliza equipos eficientes: Boquillas y tuberías de mala calidad pueden llevar a que se use más aire comprimido del necesario. Examina los cilindros neumáticos para asegurarte de que están correctamente dimensionados para sus aplicaciones específicas.

- Soluciones alternativas: Poseer un sistema de aire comprimido no significa que sea la solución más eficiente para todas las aplicaciones. Puede haber alternativas para casos de uso específicos en tu instalación que aumenten tu ahorro energético. Ejemplos incluyen bombas de vacío y sopladores de baja presión.

- Automatización encendida y apagada: Simplemente apagar los sistemas de aire comprimido cuando no se usan ofrece un ahorro energético considerable. Teniendo en cuenta que el error humano es una causa común de daños y pérdidas, una política estricta de encendido/apagado puede no ser tan eficaz como una solución automática de apagado.

8. Implementar un diseño adecuado

Los compresores con un sistema de distribución bien diseñado ofrecen mejor rendimiento y eficiencia. Un diseño de sistema de bucle para la distribución de aire, por ejemplo, es mejor que las líneas sin salida. Proporciona al aire múltiples caminos para llegar al punto de uso final, mejorando el flujo de aire y reduciendo las caídas de presión.

Un sistema de tuberías eficaz también debe tener menos curvas y accesorios. Estas restricciones favorecen caídas de presión, y lo mismo ocurre con un tamaño incorrecto.

Además, el sistema debería utilizar desagües automáticos en los receptores de aire y filtros para evitar la acumulación de condensados responsables de la corrosión acelerada y el aumento de las caídas de presión.

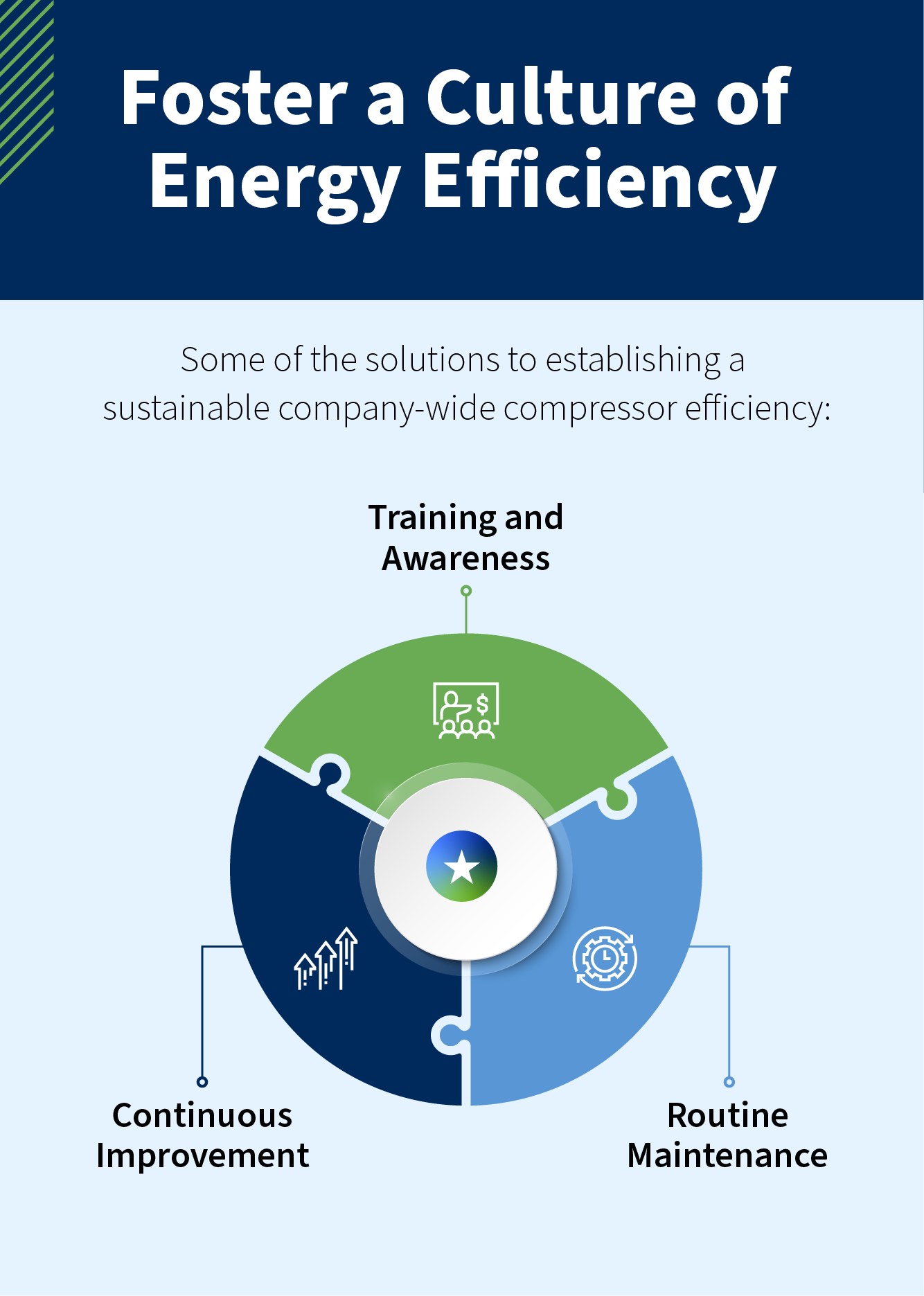

9. Fomentar una cultura de eficiencia energética

Aunque es necesario centrarse en los aspectos técnicos para mejorar la eficiencia energética de tu compresor, es importante considerar un enfoque integral para crear un programa sostenible de eficiencia energética. Muchas de estas tecnologías y estrategias inteligentes dependen de un componente vital: tu equipo.

Para un sistema que puede representar fácilmente el 30% o más de todo el consumo energético industrial, es recomendable establecer una cultura de eficiencia energética que fomente una mentalidad colectiva que impulse los objetivos energéticos. Aquí tienes algunas de las soluciones para establecer una eficiencia sostenible en todo el tamaño de la empresa:

Formación y concienciación

El conocimiento es clave para ayudar a los empleados a comprender las implicaciones de sistemas comprimidos ineficientes. Crear programas de formación en dispositivos para su uso en todos los grupos de empleados, desde operadores y técnicos de mantenimiento hasta el personal directivo. Las habilidades prácticas en operación y resolución de problemas reducen errores humanos, mejoran el mantenimiento y aumentan la conciencia.

Mantenimiento rutinario

Los compresores dependen del mantenimiento rutinario para un rendimiento óptimo. Considera implementar un plan de mantenimiento proactivo que vaya más allá de las reparaciones reactivas. Desarrolla una estrategia eficaz de mantenimiento preventivo que tu equipo o técnicos puedan seguir para garantizar la eficiencia.

Mejora continua

La eficiencia a largo plazo del compresor requiere una mejora continua y adaptación a las necesidades cambiantes. Programar auditorías periódicas del sistema para recopilar datos de rendimiento e identificar áreas de mejora, desde la detección de fugas hasta el reemplazo total del compresor. A medida que surgen nuevos avances en la tecnología de aire comprimido, quieres adaptarte y aprovechar soluciones más eficientes energéticamente.

Mantenimiento de la eficiencia energética de los sistemas de aire comprimido

Abordar los retos de eficiencia energética de tu sistema de aire comprimido ofrece una solución poderosa para reducir los costes operativos, mejorar el funcionamiento general de las instalaciones y disminuir la huella energética de tu instalación. Para mantener la eficiencia energética a largo plazo, es necesario un enfoque holístico que combine aspectos técnicos y un compromiso con la optimización continua.

Los sistemas de aire comprimido son una máquina imprescindible en muchas industrias. Sin embargo, su relevancia no significa que debas asumir facturas de energía desorbitantes. Prueba las soluciones recomendadas, como invertir en auditorías de aire, resolver fugas y optimizar los controles del compresor. Si el desperdicio energético sigue siendo una preocupación, considera estrategias avanzadas como la automatización, la recuperación de calor y la actualización a los sistemas más recientes.