Equipment failure is a consistent danger to your company’s production schedule, whether it’s from overdue maintenance or unexpected breakdowns. Compressor systems are particularly prone to such problems — malfunctioning air compressor systems cause several days of downtime each year, costing companies vast amounts of money, not only in maintenance, but also in reduced productivity. Despite the high costs, however, air compressor maintenance services have historically been reactive rather than proactive, wasting time and money on getting a technician to fix problems as they occur.

While air compressor technicians are sometimes necessary to fix unexpected failures, most of the issues these technicians handle are the result of improper maintenance. Just imagine what it would mean for your business to be able to avoid the costs and periods of downtime associated with ill-maintained air compressors. Cellular air compressor connectivity can do that.

Optimizing your air compressor system technology is simple when you use cellular connectivity to gain real-time insights. With data monitoring of your systems, you’re a mouse click away from real-time compressor room data from both onsite and remote locations, meaning you and your maintenance crews can be exactly where you need to be at any time. Quincy offers this with Q-Control, combining the latest PLC controller technology with Quincy’s cutting-edge compressor controller software. Q-Control’s cellular connection system makes it easy to stay on top of your air compressor maintenance.

Still not sure what cellular connectivity is or what it can mean for your business? Read on to learn more about compressor system cellular connectivity technology.

What Is Cellular Connectivity?

Cellular connectivity is a form of remote connectivity that uses a cellular connection to monitor the performance of a piece of equipment. Remote connections allow businesses to see how their machines are performing during use — for example, these links can enable users to keep track of the operating conditions, efficiency, energy consumption and usage patterns of connected equipment. That helps them avoid checking equipment in person, which costs consistent time and labor, and often means your maintenance crews are checking locations that don’t need assistance.

Historically, organizations have achieved remote connectivity through a variety of means. Typically, remote monitoring solutions tend to fall into one of two categories: wired or wireless.

- Wired connections: In wired connections, the built-in infrastructure locks signals into a specific location range, meaning that system information is only available within that range. While these connections are very reliable, they are also expensive to install, and the physical connections can corrode over time.

- Wireless connections: Wireless connections use technologies like radio, Wi-Fi, Bluetooth and cellular connections to transfer data from one location to another. These connections vary regarding signal strength and reach, with Bluetooth and radio signals being the most limited. Radio signals tend to be more prone to interference, while Bluetooth signals only work over short distances. Additionally, many wireless connections still connect to local data storage devices, meaning that data is still locked by location.

While both of these solutions can present data in real time, being locked into a specific location makes it difficult for multi-site companies to use effectively. Because small functional problems in air compressor systems can escalate to machine failure relatively quickly, businesses need a way to see all their air compressor data in real time across multiple locations. While many wired and wireless connections can’t provide the visibility air compressor systems need, there is a solution that can — cellular connectivity.

Cellular connections are significantly more stable and more versatile than other connection methods, allowing for improved remote monitoring solutions through:

- Long-distance capability — Cellular connections transmit over much greater distances than many other connection types, allowing for signals to travel from much more remote locations without using as many relay nodes.

- Excellent bandwidth — Cellular connections have excellent bandwidth and transmission speeds compared to other solutions, meaning data can travel faster.

- Minimal interference — Cellular connections are more resistant to interference compared to many radio and Bluetooth connections, making them less prone to data corruption and loss.

- Existing infrastructure — The communication infrastructure for cellular connections is already up and running, thanks to cellular providers. As a result, system operators rarely need to install relay points or physical connections, cutting back infrastructure costs.

- Direct transmission — While radio and landline connections traditionally send data to a storage device, cellular connections can send information directly to a device or the cloud, allowing for more instantaneous access for maintenance personnel.

Because of these benefits, remote monitoring solutions using cellular connections can help businesses achieve more. With greater transmission capabilities, your business can gain greater visibility of your air compressor systems. Even better, data monitoring systems using cellular connections are efficient and highly customizable, allowing your business to see everything you need to know about your air compressor systems.

How Does Cellular Connectivity Work With an Air Compressor?

Cellular connectivity is standard in several industries — from connected security cameras and public street lights to supply chain asset tracking, remote monitoring helps improve functionality across a wide range of systems by allowing companies to see things as they are happening. But how exactly can it help with air compressor systems?

Here’s how cellular connectivity works in conjunction with air compressor systems:

-

- Data collection — First, the master controller on your air compressor sends records of all your compressor’s information to the connected cellular modem. This information includes anything you have specified the modem to connect, including the running hours of the machine, the loaded and unloaded hours, the discharge temperature and pressure, service alerts, E-stop alerts and more. The Quincy Compressor cellular modem is called the ICONS box.

- Data transmission — The cellular modem collects and bundles the information from the master controller and sends it to the cloud using Q-Connect, Quincy’s cutting-edge compressor controller software. This connection only works one way — infiltrators in the cloud system will not be able to override the master controller of your air compressor system by connecting to your cellular modem.

- Data processing — Once the data from the cellular modem reaches the cloud, software processes it and turns it into something users can easily understand. Essentially, the data becomes customer-facing information, like pressure and temperature trends, cubic-feet-per-minute calculations, kilowatt benchmarking and service due dates and alerts.

- Data access — All the collected data in the cloud gets organized and presented on a website the user can log into, using private credentials. From here, any authorized user can see all the insights and messages the cloud received from the compressor systems and keep abreast of the service needs of each compressor system.

By gaining access to operational information about your air compressor, your business can gain insight into the operation of your compressed air production systems. These insights are incredibly powerful for your business, allowing your company to save energy, cut costs and avoid downtime.

What Are the Benefits of Using Cellular Connectivity for an Industrial Air Compressor System?

Air compressor data monitoring is a powerful tool that can help your business achieve optimal operational efficiency, but how exactly does it help you accomplish that? The answer is insights. Insight into your air compressor data is the real power of Quincy’s compressor system monitoring technology. Compressed air is your resource, but a data monitoring system enables you to gain knowledge into how well you are using that resource and how you can maintain your equipment to keep it available.

Imagine what it would mean to your business if you could always be one step ahead. Quincy’s air compressor data monitoring system does precisely that by tracking the data your machine puts out — including running hours, discharge data and service alerts — and organizes it for easy viewing so your technical and maintenance teams can respond quickly to problems, identify areas of improvement and schedule preventive maintenance as needed.

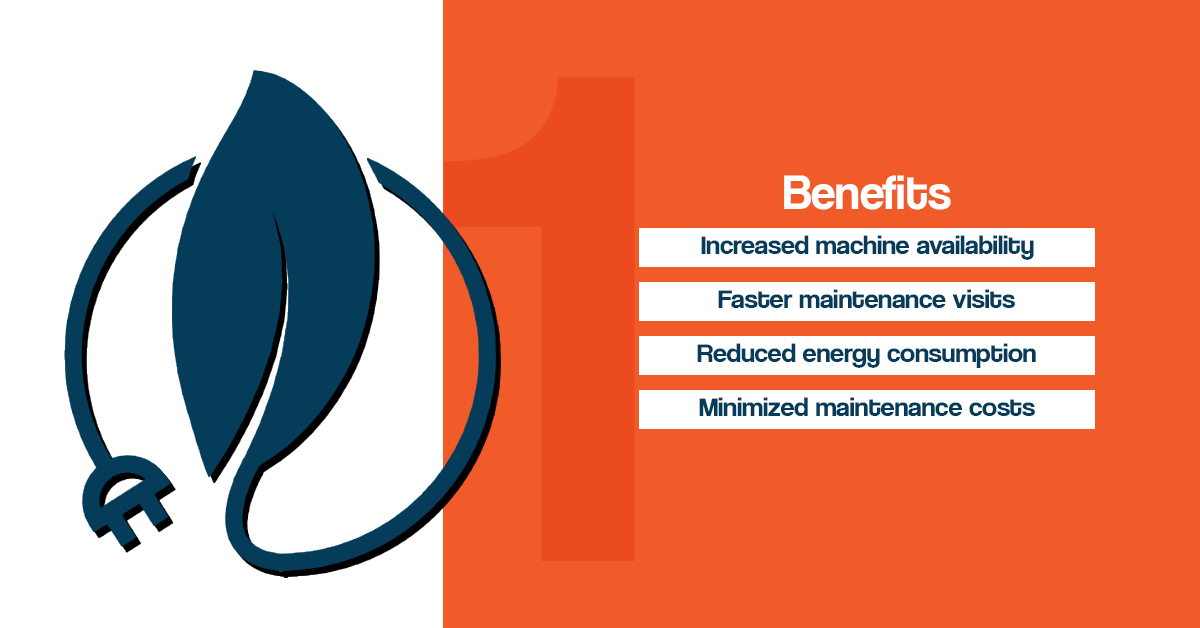

While this may seem like a basic benefit, the ability to prevent maintenance issues and optimize air compressor functionality is vital for any business with an air compressor. Just by using these insights, your business can experience the following benefits:

- Increased machine availability — Staying on top of your system maintenance alerts with a monitoring system allows you to avoid downtime as much as possible. While not all equipment failures are easily predictable, being proactive about equipment maintenance and reacting to system failures quickly can keep downtime to a minimum, allowing your business to meet your deadlines and maintain high levels of productivity. On average, businesses that service their machines regularly and correctly experience 10 to 15 more days of equipment availability per year than organizations that do not.

- Faster maintenance visits — If your air compressor system fails, Quincy Compressor’s air compressor data monitoring system makes it easier to get things running again. As soon as a system starts to fail, the data monitoring system sends out an event alert to system administrators, complete with detailed information about the problem and where it is occurring. This data allows your maintenance crew to see detailed information about the event, predict what the problem is and ensure they have the right tools available before they even head to the location. It minimizes the need for service delays, allowing you to get your air compressor up and running as quickly as possible with fewer service costs.

- Reduced energy consumption — Poor air compressor maintenance not only increases downtime, but it also increases your compressor’s average energy consumption. That’s because regular maintenance allows your business to catch potential sources of energy waste, including dirty or broken parts. These same untreated issues can turn into causes of system failures. Data monitoring can detect potential problems early by analyzing trends in air compressor performance, so your maintenance crews can find and fix these issues even sooner, saving more energy.

- Minimized maintenance costs — Between part replacements and labor costs, air compressor repairs are expensive. Fortunately, data monitoring can help reduce your maintenance costs, even if your equipment breaks. One of the most significant costs of air compressor repair is the labor involved — every aspect of organizing and sending labor crews out into the field requires paying the maintenance crew members for their time. With a data monitoring system, you can identify exactly where to send your maintenance crews and give them an idea of what they are looking for to fix the equipment. Not only does this help you get your equipment up and running more quickly, but it also allows you to save money on labor costs.

- Improved efficiency — One of the best benefits of data monitoring is air compressor efficiency. While regular air compressor maintenance is a crucial part of improving equipment efficiency, data monitoring can take it to the next level by analyzing compressor data over time. Monitoring these trends not only allows your company to identify and fix problems as soon as they arise, but it also allows you to stay connected to your air compressor usage overall, adjusting your system and optimizing it to your needs. That means your business can achieve long-term efficiency through system optimization.

- Maximized lifespan — Air compressors are a significant equipment cost, so it’s natural for your business to want to keep yours running for as long as possible to get the best return on investment. Ideally, each air compressor your business purchases will return your investment thousands of times over, but you realize fewer profit margins with poor maintenance habits. Improper or infrequent maintenance can reduce your air compressor’s overall lifespan, therefore cutting into your ROI. By staying on top of potential problems and scheduling regular maintenance with a data monitoring system, your business can maximize the lifespan of your air compressor as well as your ROI.

- Cost savings — Repairing an air compressor and its peripheral parts can be costly, but that’s not the only expense to consider. Reduced efficiency, increased energy consumption, higher maintenance costs and decreased productivity all reduce your company’s annual earnings. With data monitoring, you can avoid all this. Between reduced downtime, improved energy consumption, improved efficiency and a maximized lifespan, your business can save thousands with a quality data monitoring system. Decrease your overhead and increase your productivity with a system that helps you schedule maintenance exactly when and where you need it. Even better, the money you save with data monitoring can help you invest in better equipment down the line, further improving your performance and profitability.

In short, using cellular connectivity for your air compressor system can help your business keep your air compressor systems functioning more efficiently for a longer time, allowing you to cut costs and achieve maximum productivity with your compressed air resources.

How Does Quincy Compressor’s Data Monitoring System Offer More?

Data monitoring systems are immensely helpful for air compressor systems, but each system offers a unique range of features and benefits. Quincy Compressor’s data monitoring system offers some specific features that can help take your business’ air compressor systems to the next level of efficiency. These features include:

- The ICONS RighTime — RighTime helps you plan and avoid uncertainties by predicting your costs and resource usage ahead of time. RighTime allows your business to generate service quote requests, request service status consultations and track maintenance history, all in a single, user-friendly platform.

- The ICONS UpTime — UpTime enables you to prevent equipment breakdowns with user-friendly alerts and maintenance scheduling. Avoid downtime, save money and increase your production uptime with paid features like text message, email and maintenance pre-alerts that let you know when your equipment needs service.

- The ICONS OpTime — OpTime offers insights into how you can ensure your equipment keeps performing at optimal levels. Use OpTime to analyze your energy consumption, equipment usage habits and other factors that can affect your operational costs, so you can identify opportunities to save money and increase your operational efficiency.

Using these features as part of your air compressor system’s preventive maintenance system can save your business vast amounts of time and money that would otherwise get lost to downtime and excess energy consumption. By investing in Quincy’s quality air compressor data monitoring system, you can ensure your air compressor equipment lasts as long as possible, all while saving money you can re-invest in your company’s infrastructure and staff.

Frequently Asked Questions and Best Practices for Cellular Connectivity in an Air Compressor System

Are you looking into cellular connectivity as a way to improve the efficiency and cost-effectiveness of your air compressor system, but are unsure on a few points? Here are a couple of common concerns about air compressor data monitoring:

- Do I need to worry about the security of my air compressor? With the threat of viruses and data theft becoming an increasing problem in recent years, it’s natural to be cautious about your systems and wary of adding any potential gateways to your network. Fortunately, cellular connectivity is nothing to worry about, since these connections are not tied into your network at all. Additionally, since these cellular connections are only monitoring devices and not a means of control, they will not allow hackers to halt or alter your compressor’s functionality in any way.

- Can I use data monitoring if I have different air compressor models? The short answer is yes — you can use a data monitoring modem on any machine type as long as you have an input, a power supply and a reliable signal. You can even use different input points depending on the machine — you can connect the modem to a gauging machine or an input box on an air compressor. You can even hook the modem up to the header of your system so you can monitor multiple instruments and flow meters at a time.

- What are some best practices for cellular connectivity? The essential point to remember is that you need to incorporate connectivity into your business’ routines and operations thoroughly. It’s not just about connecting and monitoring machines, though that is a crucial component for cellular data monitoring to be of any use to you. Make monitoring a priority in your business by assembling a team and setting up a regular schedule to check the data for unusual trends and warning signs. Also, ensure your staff is making the most of the system by setting them up to receive text or email alerts.

Are you still unsure about cellular connectivity and how it can help your air compressor system? Find a dealer near you to learn more about Quincy Compressor’s unique monitoring solutions and how they can help your business achieve more with your compressor system technology.

Learn More About Compressor System Technology

If you want to stay on top of your compressor maintenance, Quincy Compressor has the right tools for you. Quincy Compressor has been America’s leading supplier of air compressors and pneumatic tools since the 1920s. In the century since then, we have continued to be an innovator in the air compressor industry, expanding our reach to include even more compressor technology, including support and monitoring systems. Today, you can find Quincy Compressor technology in businesses across the world. You can trust us to have the air compressor technology your business needs.

Learn more about Quincy Compressor’s products and solutions today, or find a nearby Quincy Sales and Service representative for more information.