Chapter 4: What’s Changed With the Updated Standards?

Before 2017, not enough attention was given to air compressor efficiency on a federal level, and there were no official DOE air compressor test procedures. Since the department developed new test procedures, air compressor manufacturers have had opportunities to comment on the standards and express their concern before they became the final rule.

In this chapter, we will look at how the standards for air compressor efficiency changed over the years. We will also explore the updates made to the standards from the NOPR to the final rule.

The Energy Policy Act of 2005

The EPAct was the first significant piece of federal energy legislation since 1992. The act focuses on 16 specific products and directs the department to set standards on several other products. In the act, products with standards include commercial air conditioners, unit heaters, commercial refrigerators and others – not air compressors. This legislation provided credit to manufacturers for very efficient refrigerators, clothes washers and dishwashers. This act discusses many appliance standards but does not implement them. Although the EPAct does not draw much attention to air compressors, it reflects a growing concern for energy conservation and appliances.

The Energy Independence and Security Act of 2007

The EISA focuses on fuel economy and renewable fuel standards. The act also includes a variety of new standards for lighting, and residential and commercial appliances such as refrigerators, freezers and electric motors. Lastly, the act increases funding for the department’s Weatherization Assistance Program and creating energy-efficient federal, residential, and commercial buildings. Although this act covers electric motors, it does not specify standards for air compressors. The act made procedural changes to accelerate the department’s rulemaking process.

Appliance and Equipment Standards Program

This program is implemented by the department’s Building Technologies Office (BTO). It was initially authorized to develop, revise and implement energy efficiency standards set by the EPCA in 1975. These standards have been regularly updated and expanded since then. In 2015, It saved consumers $63 billion on their utility bills.

The program currently provides resources for consumers and issues regulations for appliance and equipment standards and test procedures. The new air compressor test procedures are part of the Appliance and Equipment Standards Program. The program requires regular updates to amend old standards and expand the list of products subject to standards.

Current Amendment Regarding Air Compressors

The amended EPCA, as part of the Appliance and Equipment Standards Program mentioned above, includes air compressors and authorizes the department to establish standards. The department has determined that adopting new energy conservation standards for air compressors would result in significant conservation of energy.

Currently, standards are in the pre-publication phase. The new standards will first come into effect in 2022.

How the Standards Are Different in the Final Rule

The department made several changes to the NOPR in the final rule in response to the comments and concerns expressed by several air compressor manufacturers. Although many of the standards remain unchanged, some differences include the following:

1. Terminology

In some instances, air compressor manufacturers requested that the department change specific terms used to define air compressor components. For example, in the NOPR, the department defines water-cooled compressors as a compressor that uses chilled water to cool the compressed air. In response, air compressor manufacturers claimed that the term “chilled water” is limiting. The department decided to use the word “liquid” instead of “water” in the final rule to be broader.

2. Criteria

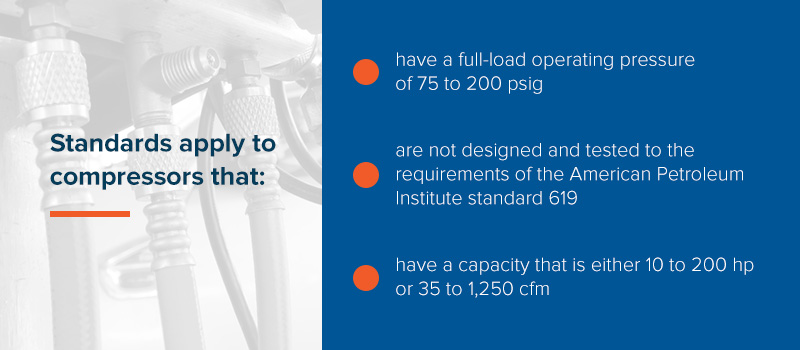

In the NOPR, standards apply only to compressors which are distributed in commerce with horsepower (hp) greater than or equal to 1 and less than or equal to 500 hp and which operate at a full-load operating pressure of greater than or equal to 31 and less than or equal to 225 pounds per square inch. In the final rule, the department removes that information and adds the following to be more specific:

- Standards apply to compressors that have a full-load operating pressure of 75 to 200 psig.

- Standards apply to compressors that are not designed and tested to the requirements of the American Petroleum Institute standard 619.

- Standards apply to compressors that have a capacity that is either 10 to 200 hp or 35 to 1,250 cfm.

3. Test Procedure Equipment

In the NOPR test procedure, the department uses the term ancillary equipment to serve as a catchall for package components that do not fall into another category but were part of the package purchased by the consumer. In the final rule, the department establishes two lists of equipment required for test procedures. They also revise the NOPR to allow the uses of an alternative efficiency determination method (AEDM) instead of testing. This method sides more with the scope recommended by the Compressed Air and Gas Institute (CAGI) and other manufacturers. An AEDM is a mathematical calculation a manufacturer can use to predict the energy efficiency of a basic model. It’s intended to reduce the testing burden for manufacturers.

4. Equipment Classes

In the NOPR, the department analyzes rotary and reciprocating compressors as separate equipment classes. However, in the final rule, the department does not propose energy standards for reciprocating compressors because the NOPR analyses show they are not economically justified.

Also in the NOPR, the department proposes creating equipment classes based on compression principle, lubricant presence, cooling method, motor speed type and motor phase count. In the final rule, the department establishes fewer equipment classes, and the remaining equipment classes are differentiated only by motor speed range and cooling method. For example, the department is not creating separate classes for lubricant-free compressors.

5. Standards Left Unchanged

Some of the standards, terminology and methods remain the same in the final rule as the NOPR. For example, in the NOPR, the department discusses the possibility of establishing standards at the compressed air system (CAS) level but ultimately decides to prepare standards only at the packaged compressor level. This is because each CAS features a unique installation and may include different equipment from different manufacturers. A CAS might also include several different types of compressors. In the final rule, the department concludes that a CAS is not appropriate for the final rule.

The department also continues to determine that gas-run compressors are unique and should be addressed in a separate rulemaking. They’ve decided it is best to limit the final rule to only compressors driven by electric motors.