The Right Air Compressor for Plastics Manufacturing

The plastics industry is booming, with no sign of letting up soon. To put the power of plastics into perspective, consider these statistics from the Plastics Industry Trade Association:

- Plastics manufacturing is the third-largest manufacturing industry in the United States. This industry accounts for 885 thousand jobs in all 50 states, and $380 billion in annual shipments.

- When you add in suppliers, plastics manufacturing in total accounts for 1.4 million jobs and $465 billion in revenues.

- And this is just in America! Across the globe, plastics manufacturing plays an important role in economies of every size. According to IBISWorld, plastics is a $739 billion industry worldwide.

Clearly, plastics manufacturing is a lucrative and economically important industry. Whether on the supply or demand side of the industry, people everywhere benefit greatly from high-quality plastics in the form of numerous products and applications. Whether someone is installing PVC plumbing, wearing protective sports gear or drinking a favorite beverage on-the-go, they’re able to do so because of the hard work of plastics manufacturers.

However, a thriving plastics manufacturing sector can only continue if they can deliver the goods. And delivering the goods requires power.

In the plastics manufacturing industry, precision, reliability and energy efficiency are paramount. Plastics manufacturing requires delicate operations in order to ensure quality. Simultaneously, power must be delivered consistently in order to keep manufacturing systems operating. Finally, any power generator in the 21st century must be energy-efficient in order to minimize energy costs while keeping up with stringent energy use regulations.

That’s why air compressors have become the standard for driving plastics manufacturing. Industry leaders employ air compressors for plastics manufacturing because they are the best suited devices for providing consistent, precise and reliable power.

With that in mind, we wanted to put together this guide on finding the best air compressor for plastics industry manufacturing. Within it, we will discuss exactly why air compressors are your best solution for providing your manufacturing operation with the power you need. We’ll conclude with some specific solutions for meeting your plastics manufacturing needs.

Precision

The delicate nature of high-quality plastics manufacturing requires precise power delivery. That’s why air compressors are so well-suited for use in the plastics industry.

While fluctuations in electrical current can have catastrophic consequences for a manufacturing line, pneumatic air compressors absorb these fluctuations and continue to deliver consistent, unwavering power.

Furthermore, air compressors give you unrivaled control over the level of power, meaning you can adjust your output to perfectly fit your needs. This kind of control is essential for maintaining quality while also being energy- and time-efficient. By tailoring your power output to exactly fit your power needs, you won’t waste power, while at the same time ensuring you have power available to meet needs elsewhere.

Reliability

Anyone in manufacturing knows that if the line isn’t running, money is being lost. That’s why you also want power you can count on when you need it. Air compression provides you with the level of reliability you need to keep your lines moving and your profits maximized.

Let’s return to the problem of energy spikes and other electrical fluctuations. Because air compression is stored when not in use, initiating an operation does not result in spikes in energy use. A similar, all-electric process does. As a result, electrical operations that do not use air compression are prone to tripping fuses and, subsequently, shutting down operating lines. Because air compression places another sequence in the application of power, there is a buffer between initiating an operation and drawing the required energy for completing it.

Finally, across industries, air compressed tools are more reliable within harsh environments. Work places that are dusty or otherwise dirty can be difficult places for tools to operate. Air compression performs better under these conditions. The same is true for environments with large temperature variations.

By choosing pneumatics when working in plastics, you’re ensuring that your operation runs smoothly without being interrupted by malfunctioning equipment.

Energy Efficiency

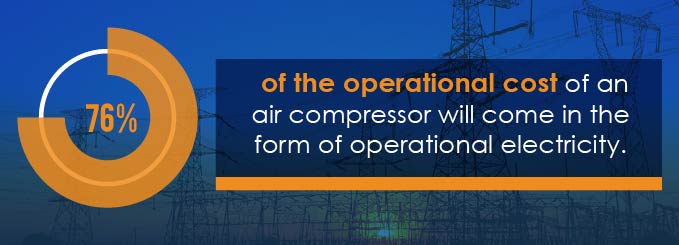

When it comes to maintaining your bottom line, energy efficiency is a serious concern.

To put this in perspective, keep in mind that air compression accounts for 17% of the energy consumption within industrial plastics manufacturing, according to a study by Leonardo Energy, an electric energy information initiative.

Furthermore, 76% of the operational cost of an air compressor will come in the form of operational electricity.

In other words, it is imperative that you consider energy efficiency when choosing an air compressor. While a good air compressor will provide you with the power for the tools you need, while being gentle on the energy budget, an aging and inefficient air compressor will quickly drain you and your operation of its profits.

Worker-Friendly

In addition to being the best solution for management, air compression makes work easier for employees as well. Tools powered by air compression are safer, more lightweight, more powerful and don’t need to be recharged. Similarly, air compressor-powered assembly lines are less prone to electrical issues, which in turn makes them safer for line workers.

Ultimately, however, employers reap the benefit of better-prepared workers. Because workers using air compression tools are more efficient and less strained by their work, they are more productive and more satisfied with what they’ve accomplished.

Perfectly Suited for Plastics

Here’s the key point: air compression works best for plastics because plastics manufacturing requires operations that can only be performed by an air compressor.

One of the key operations in plastics manufacturing is blow molding. In this process, molten plastic is inflated into its desired shape. That inflation is performed by an air compressor.

Similarly, extrusion (in which molten plastic is formed into a consistent shape, such as PVC piping) and injection (in which molten plastic in injected into a mold) are also operations best performed by an air compressor.

The various operations that are specific to plastics manufacturing are best performed by air compressor-powered equipment. The very fact that air is an integral part of plastic construction makes converting your entire operation to compressed air power the smartest choice.

Hear From Our Customers

Choosing the Right Air Compressor for Plastics

However, while air compression is the best solution for plastics manufacturing, it’s important to note that not all air compressor solutions are the same. Whether you’re setting up a new operation or converting your shop into an air compression-powered plant, you want to make sure you’re selecting the air compression solution that’s going to maximize all the benefits of pneumatics.

With that in mind, here are some things to keep in mind when choosing an air compression system:

Quality Construction

While it’s true that air compression is more reliable and precise than other power solutions, these benefits are contingent upon quality construction.

Air compression requires tight seals and strong materials in order to supply and maintain the required pressure. And not only do tight seals ensure efficient power — they also prevent moisture from entering into the device, which under certain conditions could cause significant malfunctions.

Furthermore, insufficient air pressure containment will not only shut down your plant, but it can also cause significant damage and pose a danger to employees.

In addition, repair time costs money in the form of maintenance and also amounts to losing money by keeping portions of your plant from operating. Plus, the added pressure placed on an air compression system by leaks and poor construction can significantly reduce the life of your device, adding further financial strain to your budget.

Finally, high-quality construction is essential for providing the kinds of energy savings that any 21st century plastics manufacturing plant demands. Subpar construction, even if it’s only causing minor flaws, will greatly reduce the energy efficiency of your system. Every small leak or poor seal increases an air compressor’s demands for power.

Consider these statistics. According to Compressed Air Best Practices, a leak can account for a 20% to 30% loss in compressed air pressure. To put it in other terms, the same study estimates that a 1/16-inch-sized leak can cost $525 in added energy costs. Bump the size of the leak to a ¼-inch, and the energy costs rise to over $8,000!

Smart Analytics

If yours is a large operation, integrated smart analytics are essential for monitoring and maximizing your efficiency, giving you even tighter control over your operation.

Integrated intelligence puts data right at your fingertips, letting you clearly see where you need more power and where power is being wasted. Furthermore, if there is a chain in your operation that isn’t performing at peak efficiency, integrated intelligence will allow you to address that malfunction quickly and efficiently, helping you get your operation up and running at full speed with minimal delay.

Manufacturer Support

Finally, you want an air compressor manufactured by someone who stands by their products. A quality manufacturer isn’t afraid to observe their own tools at work in your plant.

You want an air compression manufacturer who will see themselves as a partner for the entire life of the compressor. If something goes wrong, a partner who is intimately familiar with the solution will be quicker to diagnosis the issue. Furthermore, they will be able to direct repairs quickly and efficiently, keeping repair and downtime costs to a minimum. Finally, they will be ready with expert advice on making your air compressor work even better for you.

Quincy Is the Perfect Plastics Pneumatics Solution

Luckily, there’s an air compressor manufacturer that not only offers the perfect solution for plastics manufacturing, but is also the kind of trusted partner that will stand behind their work.

Here at Quincy Compressor, we have spent nearly a century providing the highest-quality air compression for the leaders in a wide range of industries. Whether plants are looking to power their metal fabrication, woodworking, plastics, food and beverage or even dry cleaning operations, Quincy can provide the appropriate air compression solution, perfectly suited for each industry and plant’s particular size and application.

Consider our own patented EQ/Efficiency Quotient. Through this process, we demonstrate our own commitment to the quality of our compressors, as well as our desire to drive innovation in energy efficiency. Our compressors are industry leaders in the 21st century.

The process begins with a free plant walkthrough, in which we identify your pre-existing energy quotient and establishing a baseline in regards to cost and energy use. This baseline will then be used to define where energy and cost savings can be found within your particular operation. Using patented data analysis tools, we’re able to determine your exact power and air compression performance throughout your plant.

After collecting the data, we use it to give you a detailed cost analysis, along with an action plan to help you fully grasp the capital investment and savings potential for making changes in your air compressor usage. To help you further, we will even give detailed and specific recommendations that are aligned with industrywide best practices.

But we’re also dedicated to giving you constantly updated data analytics. That’s why many of our air compressors are equipped with industry-leading integrated intelligence. With such integrated analytics, you can stay on top of your efficiency and costs throughout the year, helping you make small adjustments on the fly. We know that even a minor tweak can save you big money in the long run.

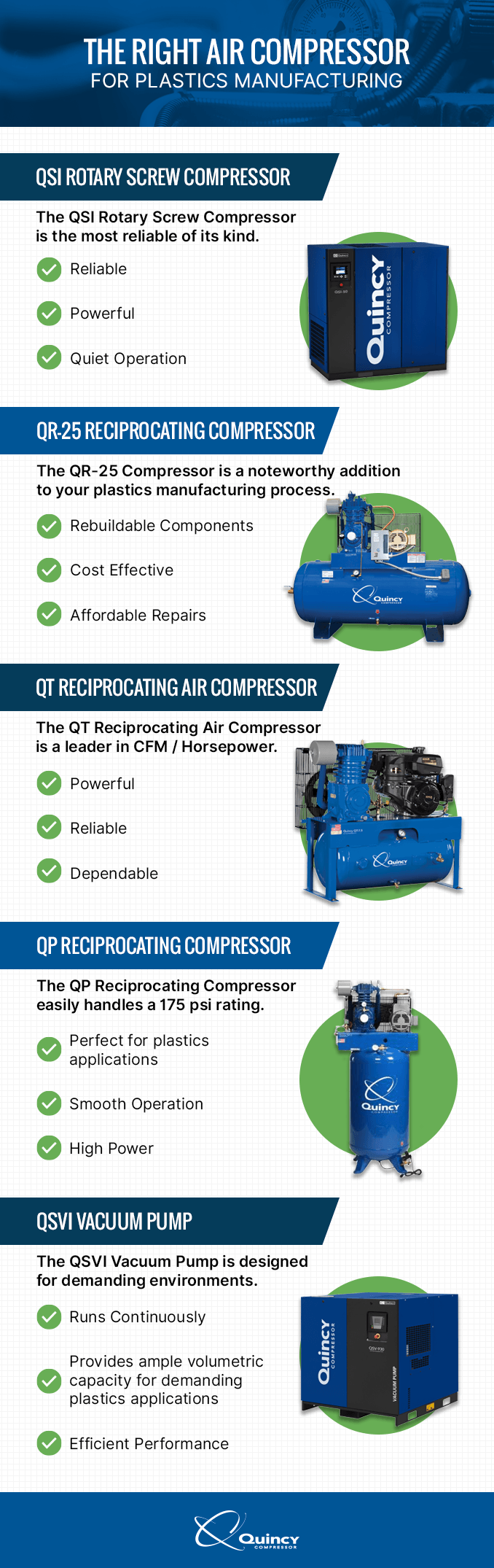

If you’re looking for the best air compressors for plastics applications, there are a number of solutions that we suggest:

| QSI | QPNC |

| QGV | QED |

| QGD | QPVS |

| QGS | QCMD |

| QGDV | QHP |

| QGSV | QHD |

| PPNG (PSA N2 Generator) | QBP |

| Cool Dryer |

With such a wide range of solutions perfectly suited for an equally wide range of applications, we are confident that, here at Quincy Compressor, we can meet your specific air compression needs. We know that the plastics manufacturing industry is demanding, just as the consumers who use your products demand the highest quality. That’s why we’re uncompromising in our craftsmanship and have been since we first opened our doors in 1920.

So: if you’re ready to explore exactly how we can provide you with the perfect air compression solution tailored to your needs, contact one of our friendly and knowledgeable sales representatives today. We look forward to providing you with the perfect air compressor to get your plastics manufacturing plant operating at peak efficiency.