Green energy helps companies reduce operational costs and contribute to the country’s sustainability efforts. Investing in an energy-efficient air compressor is one of the most effective ways to increase your company’s sustainability, reduce emissions and save money.

Why Go Green?

Going green offers the following benefits:

Green Energy Savings

Using energy-efficient green production systems can help your company conserve energy and save money. While a more efficient air compressor model typically has a higher upfront cost than other models, it can significantly reduce your power consumption. Green air solutions help you save money on energy bills, helping you increase your profits.

Sustainability

Green production systems also help companies reduce their carbon footprint. Using energy-efficient systems can minimize your emissions and help decrease national power consumption. This can help your company meet future environmental standards as they gradually become more stringent.

Increased Customer Base

Consumers are becoming more environmentally conscious. Green manufacturing attracts more customers who want to work with companies that contribute to a healthier environment. You can significantly increase your customer base by implementing sustainable production solutions.

Replacing older compressors with efficient solutions lets your target audience know your company is a responsible organization that cares about preserving resources.

Healthier Work Environment

Green technology can also help you create a healthier work environment. Oil-free air compressors contain no oil, so they make clean compressed air that can help keep your facility safer for employees.

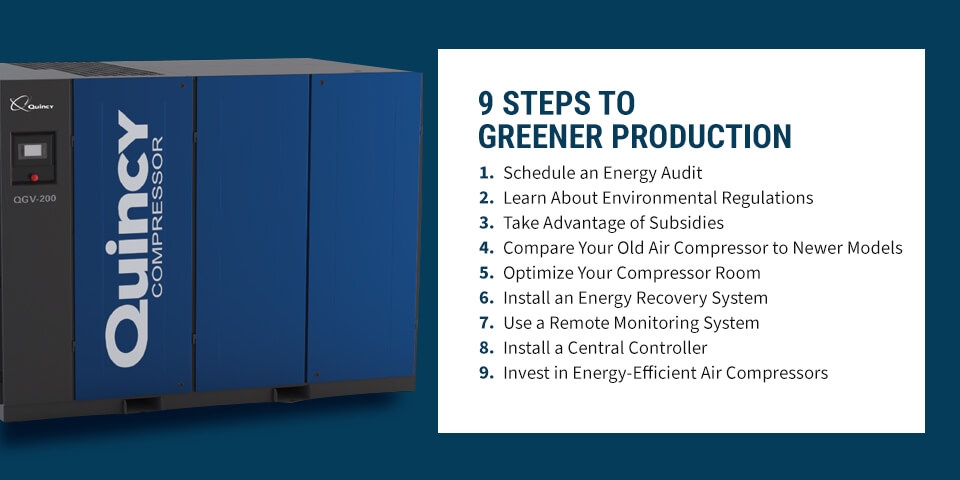

9 Steps to Greener Production

You can implement greener production processes and improve your company in the following steps:

1. Schedule an Energy Audit

An energy audit provides insight into your current air compressor system’s condition. A compressed air expert can identify inefficiencies and issues, such as leaks that require maintenance and repairs. An audit can also tell you if it’s time to upgrade your air compressor. If your company uses several air compressors in a network, an expert can identify which compressors you should replace first.

2. Learn About Environmental Regulations

The government enforces environmental regulations to reduce companies’ emissions and energy consumption. These regulations can change — especially as the government increases its environmental conservation efforts. Since regulations change frequently, you should ensure your company’s processes and equipment meet applicable standards.

An older air compressor may no longer comply with emissions and energy regulations, making a replacement crucial for your company. You can choose to replace your older compressor with a new similar model or opt for a more energy-efficient option. Investing in an energy-efficient air compressor ensures you can comply with current and future government regulations.

3. Take Advantage of Subsidies

The government often rewards organizations for investing in and using environmentally friendly equipment and technology to encourage green production practices. Your company may be eligible to receive subsidies if you purchase energy-efficient air compressors, so researching and purchasing eligible models may help you save more money when you go green.

4. Compare Your Older Air Compressor to Newer Models

Comparing your older compressor to new energy-efficient models shows you how much energy and money you can save. Check your compressor’s power consumption and examine your energy bills. Keeping your older model or purchasing the same or a similar model may seem cheaper, but an energy-efficient model’s energy savings reduce its total cost of ownership and make it a better option.

You should also check if your current model operates on a fixed speed or contains a variable speed drive (VSD). VSD air compressors consume much less power than fixed-speed models, so consider switching to a VSD model to optimize energy efficiency.

5. Optimize Your Compressor Room

A compressor room houses an air compressor or a compressor network and increases its efficiency. Intake air must be clean for the best compressor performance. Compressors produce wasted heat, so ventilation is essential. A well-ventilated compressor room ensures your system operates with clean air at appropriate temperatures.

6. Install an Energy Recovery System

An energy recovery system is another option that can optimize your compressor room. Energy recovery systems turn wasted heat into reusable power. Make sure new air compressors are compatible with your recovery system before purchasing them.

7. Use a Remote Monitoring System

Monitoring and adjusting an air compressor’s function can enhance its operational efficiency. With a remote monitoring system, you can optimize an energy-efficient VSD air compressor’s functioning and energy efficiency. This connectivity enables you to monitor and control your system from anywhere.

8. Install a Central Controller

A central controller can increase your compressed air network’s efficiency if the network contains multiple compressors. In this type of system, a central controller activates the most efficient compressor or combination to provide optimal performance. A central controller is beneficial if your network contains at least one new, energy-efficient air compressor. It does not increase an older compressor’s energy efficiency but can maximize a new compressor’s efficiency.

9. Invest in Energy-Efficient Air Compressors

Energy-efficient air compressors are healthier for the environment and can save your company significant energy costs. When you are ready to invest in new air compressors, consider the following options:

- VSD air compressors: Variable speed drive compressors contain drives that control their speed. Adjusting a compressor’s speed decreases power consumption, produces more consistent pressure and protects compressors from power surges.

- Oil-free air compressors: Oil-free air compressors operate with no oil lubrication. An oil-free compressor contains a Teflon or water coating to replace oil lubrication, or its compression chamber contains equipment without mechanical contact.

Quincy’s VSD and Oil-Free Air Compressors

Energy-efficient air compressors help companies operate sustainably and save money. Quincy Compressor offers VSD and oil-free compressors to help companies implement greener solutions in their facilities.

The Quincy QGV®️ variable speed rotary screw air compressor produces incredibly stable pressure. This air compressor model operates reliably, is easy to maintain and has a low ownership cost. It also features touch-screen control and real-time performance monitoring.

Quincy Compressor also offers the following high-quality oil-free air compressors to power your equipment with clean air:

- QOF 2-30 hp oil-free scroll compressors: Our QOF oil-free compressors are Class Zero, representing the best air quality possible, and operate with top performance. QOF 2-30 oil-free compressors are reliable and easy to maintain. They also reduce operating costs significantly.

- WISAIR 20-75 hp oil-free water-injected screw compressors: Water-injected screw compressors use water’s cooling capabilities to remove wasted heat energy and produce more air per power kilowatt. Low compressed air temperatures also increase the compressor’s longevity by reducing stress on its components.

- QOFT 20-75V and QOF 75-400 oil-free compressors: QOF and QOFT rotary screw and rotary tooth compressors deliver 100% oil-free air and are highly reliable. They also feature advanced networking capabilities and controls.

Purchase Energy-Efficient Air Compressors From Quincy Compressor

Energy-efficient air compressors are cleaner and safer for the environment. They can help your company save money and conserve energy, contributing to sustainability efforts. Quincy Compressor offers a wide selection of energy-efficient air compressors that operate reliably, reduce operating costs and decrease energy consumption. Locate an authorized sales representative to purchase an energy-efficient air compressor for your facility.