Automotive technology has grown by leaps and bounds over the past 100 years, but one thing remains unchanged: Dozens of parts get passed along assemblies for the construction of each vehicle. Auto assembly is a job that requires teams of technicians who put together various components, both large and small. Throughout each stage of assembly, automotive air compressors dedicated to powering these processes deliver air to power to the most essential tools and operations along the production line.

Automobiles have traditionally been constructed of steel, though many component parts are now made of petroleum products like plastic, which have shaved significant amounts of weight off motor vehicles in recent decades. In any case, using pneumatic tools allows for the quick and easy assembly of car parts made from a variety of materials.

Vehicle assembly

The manufacturing of automobiles is carried out in several stages, the last of which occurs at the assembly plant, where parts from thousands of sources are combined to make the chassis and body of each individual car, truck and van. In most cases, vehicles are built from the bottom up, starting with the shell, which is set on a conveyer belt and braced to stay in place as it’s run down the production line.

Shell construction

The shell undergoes a series of additions while traveling along the assembly line past various hands and machine elements, which install everything from the gas tank, front/rear suspension and axles to the brakes, wheel drums and steering components. Throughout the majority of these steps, automotive air compressors play a vital role in putting each part into place with utmost precision and security.

Engine construction

Then comes the stage where the engine and transmission are brought together. For this task, robotic arms are used to put heavy pieces into place. Once the two components have been installed, technicians bolt down the radiator. During these stages, there’s a division of labor between the robotic arms, which do all the heavy lifting, and the human assemblers, who use air–powered wrenches to fasten each component screw. Over the decades, the tools used for these tasks have been made safer and more effective thanks to ergonomic studies regarding the flow of assembly.

Small parts

When it comes to the construction of the vehicle’s body, the largest number of smaller-piece attachments are made on the floor pan. Pneumatic tools are crucial throughout this stage, because they allow workers to accomplish in seconds what would otherwise take hours. With each shift along the assembly line, the clamp–shackled shell of the vehicle is put together, piece by piece.

Compressed air is also responsible for the role played by the robotic machinery, which lifts, transports, and positions the quarter panels, door pillars, side panels and roof pieces. Likewise, the shell of each vehicle is assembled more efficiently with the help of a robot because machine arms can bolt and weld numerous items with levels of speed and precision that far exceed human capabilities. Robots have the strength to set roof panels that weigh 200 pounds into the right position for welding. Throughout this process, robots are able to withstand the various hazardous elements of production, including smoke, gases and sparks.

The body and chassis of a vehicle are constructed on different assembly lines from one another. The majority of the panel-welding is done by robotic arms, while bolting is handled by technicians. While the welding is in progress, the shell is braced in a jig. Once the body is rotated out of the secluded welding section, additional parts are added, such as the doors, hood, fenders and bumpers. Afterwards, the shell is connected to another conveyor to undergo the painting part of the process, during which the shell is inspected, cleaned, undercoated, top-coated and baked.

Cleaning

Before the actual painting commences, the body of the vehicle must be thoroughly examined for possible surface defects. The inspection process is carried out in a white room under bright lights. Here, the body is covered in hi-light oil, which makes it easier for technicians to spot any problems with the sheet metal along the hood, roof, bumpers, fenders and doors. If bumps, dents or scratches are detected, repairs are made and the body is then sent along the conveyer to be rinsed free of oil and other possible foreign elements.

Painting

Once the body is finished with the cleaning, it goes to another stop along the conveyer to dry. Up next is the first actual painting stage, where the body receives an undercoat of primer across every inch of the outer shell. This forms a substrate layer that allows for a more solid adherence of the outer coat of paint. Before the topcoat is applied, however, the body is sent back to dry once again. Finally, the main coat of paint is applied across the outer car parts.

In most contemporary automotive plants, coats are applied by robotic arms, which are programmed to monitor exactly how much paint is needed across every inch of each vehicle. The shiny finishes that are preferred by many of today’s car owners are the result of well-studied engineering into the capabilities of robotic technology. It’s a far cry from the methods that existed a century ago, when cars were painted in the same way as houses, with brush in hand.

These innovations have been made possible by the power of automotive air compressors. They’re able to keep moisture levels low while providing consistent power levels to pneumatic tools throughout the complex steps involved with assembling and painting each vehicle that passes along the conveyor belts.

After the vehicle body has received both the primer and topcoat, it’s sent to another area to be baked at a temperature of 275° F. With the body now painted, the next steps involve the installation of interior components.

Preparation

The body proceeds down the conveyer to an area where interior assembly is performed. Here, technicians install the full range of interior pieces, including the seats, door panels, dashboard, clutch, pedals, lights, radios, mirrors, vents and speakers. Glass parts are also installed at this stage, including the windshield and door windows. The former is set into place via suction cups at the end of robotic arms, which move the glass panel out of its delivery container and into place at the front of the dashboard. For extra protection, urethane sealer is applied along the edges of the windshield before it’s set into place.

Installation

Transportation of the heavier interior components, such as the panels and seats, is also performed by robotic arms. This frees the technicians from some of the more grueling aspects of labor and allows them to instead focus on bolting everything tightly and securely into place. Once the interior is finished and each window is set into frame, the vehicle is passed to another area where it undergoes a water test. The purpose here is to ensure that the doors and windows are tight, snug and foolproof.

Finally, the stage arrives where the body and chassis are joined together. The former is lifted and set down onto the latter via robotic arms, but technicians perform the final acts of assembly. These involve bolting the two components together with pneumatic tools powered by automotive air compressors. The workforce is split between two levels, with some technicians doing their parts at ground level and others operating beneath the vehicle from a work pit. After the bolting is complete, the vehicle is passed down the conveyer to another group of workers who install the battery, apply the tires, pump the gas tank and fill the oil and coolant reservoirs.

The vehicle is now ready to be powered up and driven. Its first destination is a nearby checkpoint, where the vehicle is assessed for performance and quality on all fronts: Tire balance, engine/charging power, light/horn operation and more. If any part is found to be lacking in terms of functionality, the vehicle is sent to an adjacent area where repair workers troubleshoot the problem. Once the vehicle has passed this stage of the inspection, it’s appraised for its market value and set with a price tag. From there, the vehicle is taken to a shipping lot, from which it will ultimately travel to a dealer’s lot, either domestically or abroad.

Audits

The various parts that make up a vehicle are produced at different locations. Therefore, the planning of each vehicle is a complicated process, since every single part has to be produced, tested, readied and delivered on the date when production is set to commence. In order to ensure that everything is ready when needed, car makers stipulate that component manufacturers must test and inspect all vehicle parts prior to shipment. This allows the assembly plants to ensure that all incoming parts bear the Statistical Process Control (SPC) seal of approval and are defect-free.

Quality control

When components are first put together at an assembly plant, a Vehicle Identification Number (VIN) is given to each new car, truck or van on the production line. This allows the specialists in charge of overseeing the process to trace the development of each vehicle from “embryonic” to fully-built form. In doing so, quality control is executed on a step-by-step basis during the assembly of each vehicle, and imperfections are rectified before a body shell or chassis is sent to the next set of hands.

This marks a dramatic improvement from the days when inspections and corrections were only performed on finished vehicles, because money and time are saved in the process of assembly. Today’s assembly plant efficiency has all been made possible by automotive air compressors, which give tools the exact power needed to perform the required functions with utmost precision and speed.

At repair shops, automotive air compressors specified for this application are used to perform maintenance on numerous vehicles, some of which need new coats of paint. Whether the job involves touching up an existing coat or redoing the paint job altogether — either with the same color or something else completely — a particular type of compressor is needed to ensure the right amount of pressure is released with virtually zero moisture.

DIY

If you’re handy with vehicles, and you prefer to do your own car maintenance, you could repaint any vehicle in your garage with a pneumatic airbrush. All you need is an air compressor that can deliver the exact consistency needed for even, splotch-free coats. As you shop around for the best air compressor for painting, it’s crucial to note the capacity of a given airbrush in terms of consumption, pressure and horsepower (hp). The average amount of air that a tool consumes is defined by cubic feet per minute (cfm). For brushes used in automotive paint jobs, consumption levels are down in the 7-15 cfm range. An automotive air compressor with 3 hp will deliver right in the middle of the airbrush’s consumption range, at 10.5 cfm.

Dryers and Filtration for Error Free Painting

Achieving the perfect paint job at home also requires clean, dry, and contaminate-free compressed air. The dreaded fish-use effect results from pockets of fluid that invade the air stream. Properly used air dryers and filtration ensure a smooth mirror finish with airbrush paint products.

Capacity

To a lot of car owners, the idea of do-it-yourself maintenance seems physically intimidating. Thankfully, automotive air compressors remove much of the physical strain that would otherwise accompany the work involved in fixing engine parts and pumping or replacing tires. An air compressor with a capacity of 2.5 hp, 21 gallons and 125 psi can easily be powered up via standard outlets and used to operate pneumatic tools. For the average car owner, the compressor will easily power a simple air-impact wrench, which can be used when working on the timing belt of a front-wheel-drive car to get the front-crank pulleys removed as needed.

Tools/Functions

A variety of other car repairs can also be accomplished in a home garage or driveway with help from a small-to-medium-sized automotive air compressor. For removing nuts and bolts, an air ratchet makes it easy for virtually anyone to get the job done faster than would otherwise be possible with an old-fashioned hand wrench. When it comes to grinding metal like they do at assembly plants and repair shops, an air grinder brings the whole job home with a simple plug-in.

Likewise, the job of cutting metal can be handled by the average car owner with a small, easy-to-operate air saw. Further pneumatic car tools that can be powered by a home-operated, automotive air compressor include vacuum machines and air-powered pressure guns, which can respectively be used to suck out air and check for leaks in cooling systems.

Our Recommended Automotive Air Compressor Solutions

We recommend the following products for your automotive air compressor applications:

- QGS Series: QGS is a series of top-performing rotary screw air compressors featuring a compact design for a small footprint and quiet operation that is ideal for auto body shops and other mid-sized operations. Key features include a high-efficiency air inlet filter, reliable V-belt drive, powerful and reliable TEFC motor and a low oil carryover that provides superior protection for your tools. The range is from 5 to 100 HP.

- Dryers: We offer refrigerated dryers that can purify a compressor by chilling it to temperatures just above freezing, resulting in moisture condensation. This minimizes the presence of dirt and oil within the air stream. You’ll also find a selection of desiccant dryers that can provide reliable air purification down to -100°F PDP.

- Air filtration solutions: Our range of filtration solutions includes standard and high-pressure filters, mist eliminators and preferred elements for the highest quality air delivery free of contaminants that can corrode tools and destroy finished the product.

Learn How Quincy Compressor Can Provide the Right Automotive Air Compressor

Discover how the right automotive air compressor from Quincy Compressor can help you meet the unique air compression requirements in your automotive operation. For product selection assistance and pricing information, contact us directly or get in touch with the authorized Quincy Compressor dealer in your local area. Our dealers can also provide 24-hour service and support to keep your compressor operating at maximum efficiency.

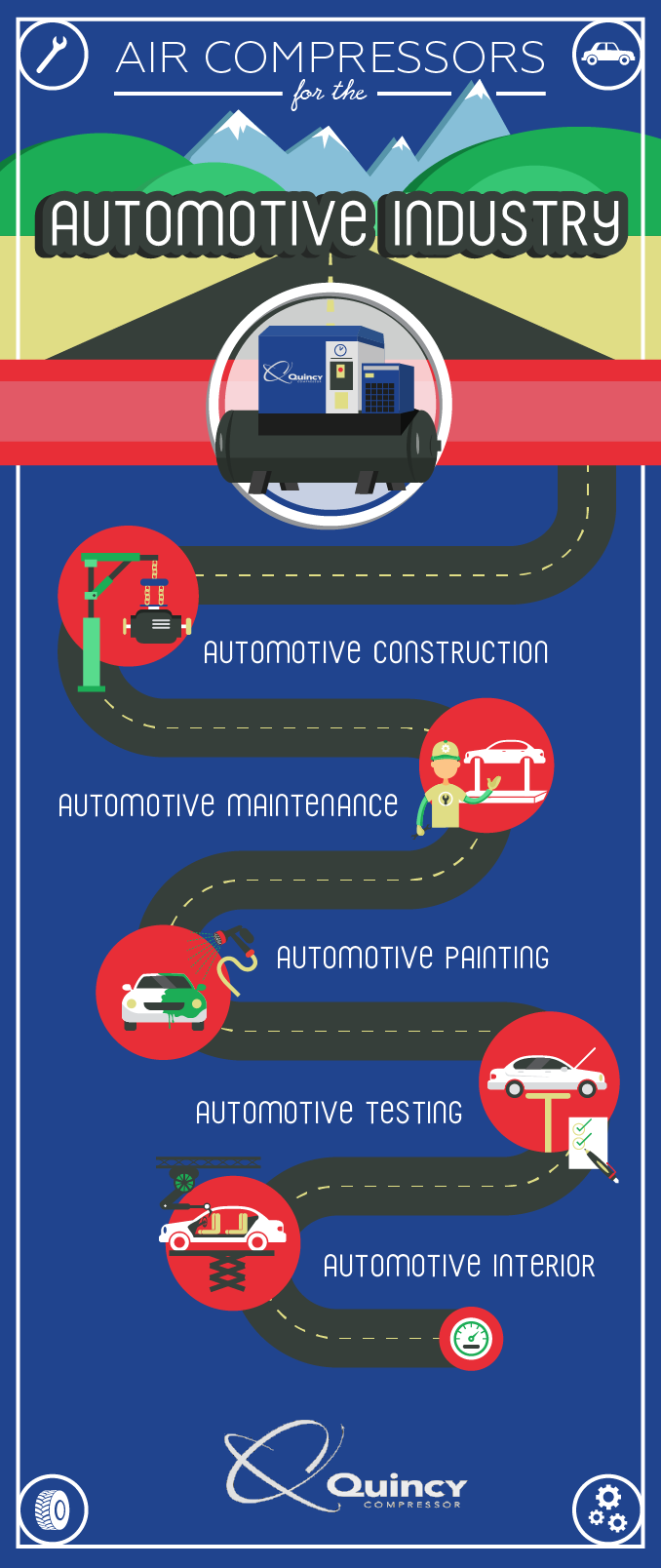

Check out this great graphic of the many ways that air compressors play a role in the automotive industry.