- 7.5-125 hp

- Variable Speed Drive

- 240-3023 ACFM

- Air or Water cooled

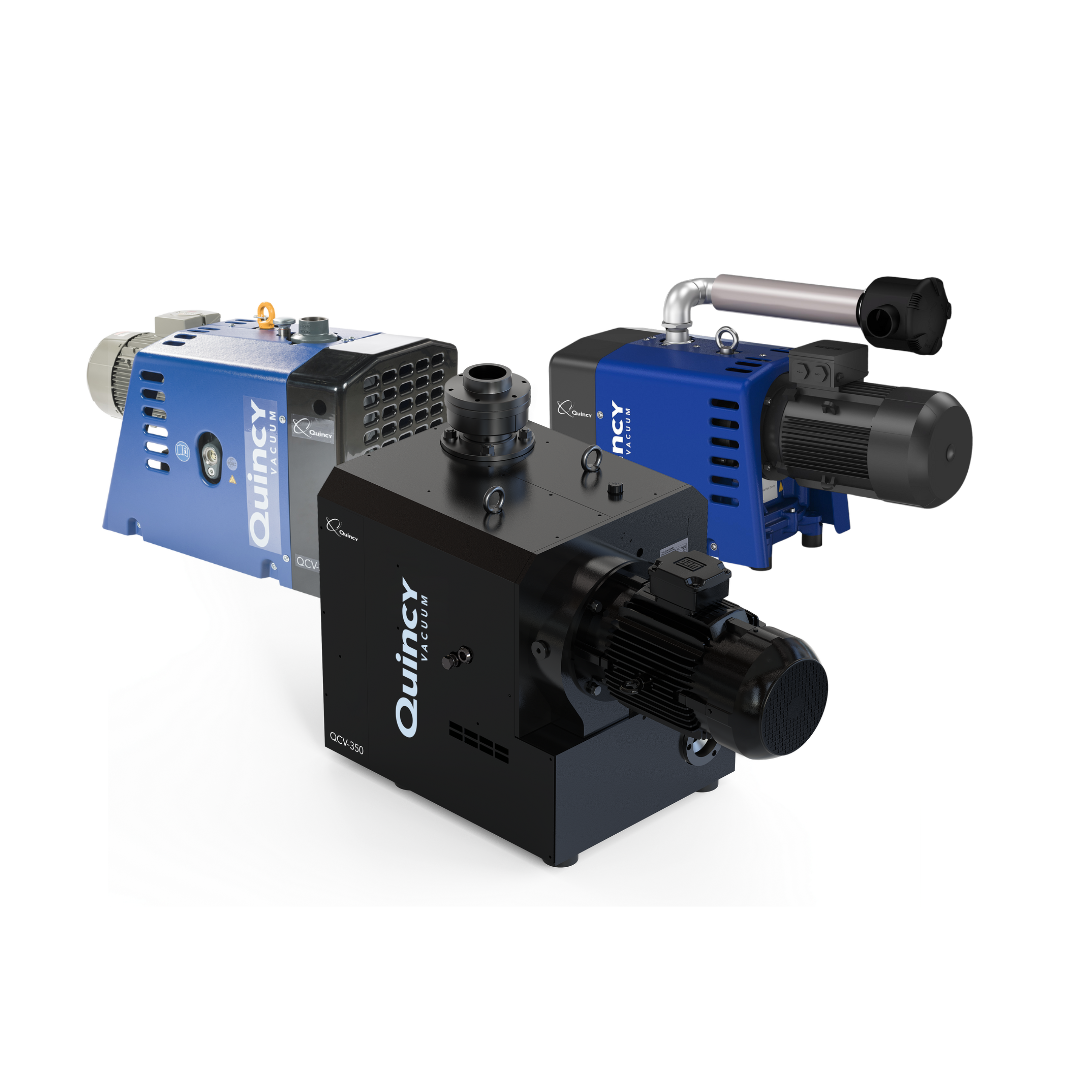

QCV & QCLP - Dry Claw

- 1.2-10 hp, Direct Drive

- 17-200 acfm

- All-purpose, rotary vane vacuum pump

Related Articles

Articles from the Quincy Compressor Blog On Vacuum Pumps

Industrial Vacuum Pump Types

- Rotary vane: Rotary vane pumps are comprised of a series of vanes that are mounted to a rotor that turns inside a

cavity. As the vanes rotate, centrifugal force extends them from their individual slots, forming compression cells that get larger to draw air in from the intake and smaller to push air out the exhaust.

- Articulated piston: An articulated piston industrial vacuum pump operates in a manner similar to that of an automobile engine. As the piston moves downward inside the cylinder, air is drawn in through the intake valve. During the piston’s upward stroke, the air is permitted to escape via an exhaust valve. Two spring-backed piston rings are used to seal the piston to the cylinder.

- Screw: Rotary screw pumnps include two parallel rotary screws in the pump housing. The screws are synchronized to turn in opposite directions, which causes the compression action to occur. The gas is compressed in the direction of the pump’s discharge port.

- Liquid ring: Liquid ring pumps also operate via positive displacement. During operation, the pump’s impeller rotates inside the pump casing. A rotating liquid ring then seals the impeller and its blades. Liquid is sucked into the compression chamber to keep the ring stable. Conveyed gas is compressed during each impeller revolution.

- Claw: Claw vacuum pumps consist of two rotors that are very close but do not come in contact with one another during rotation. As the rotors turn they physically enlarge the space between them to draw in air, then as they rotate around, physically reduce the space between them to compress the air out of the chamber.

How to Choose the Right Industrial Vacuum Pump System for Your Needs

Each industrial vacuum pump type has its advantages and disadvantages. Which vacuum pump type is right for a given process is dependent on the process itself, the environment the pump will be operating in, and the owners ability and willingness to do maintenance.

Contact Quincy Compressor or one of our authorized distributors to learn more about industrial pump vacuum systems and how to choose the best pump for your applications.

To learn more about Quincy Vacuum Pumps, check out our related resources:

What’s The Difference Between Vacuum Pumps And Air Compression

Vacuum Level: What’s a Few Inches Here or There?

Your local authorized Quincy Compressor distributor will be happy to explain the features and benefits of each vacuum pump in more detail. You can also contact us directly if you have additional questions.

cavity. As the vanes rotate, centrifugal force extends them from their individual slots, forming compression cells that get larger to draw air in from the intake and smaller to push air out the exhaust.

cavity. As the vanes rotate, centrifugal force extends them from their individual slots, forming compression cells that get larger to draw air in from the intake and smaller to push air out the exhaust.