Why Condensate Separators Are Important in Your Compressed Air System

Compressed air systems have numerous industrial and commercial applications. They can power anything from manufacturing machinery to HVAC systems. However, with the power of compression comes the inevitable byproduct — condensate. If not appropriately managed, this mixture of water, oil and debris can adversely affect your compressed air system. Corrosion, diminished efficiency and pricey repairs […]

Read MorePortable Air Compressors

When you need efficiency and industry-leading power in a small package, look no further than Quincy Compressor’s portable air compressors. Our compressors are suited for home and DIY use while still providing the reliability and power necessary for commercial applications. We build our compressors for the long haul, delivering great value in almost any situation. […]

Read MoreAir Compressor Audit Guide

Air compressors perform a crucial function for businesses in industries like manufacturing, automotive, construction, energy exploration and many others. While air compressors are essential, they consume substantial energy and can create a significant business expense. Performing regularly scheduled air audits is necessary for ensuring your systems are functioning properly and reducing your company’s short- and […]

Read MoreGoing Green: Environmentally Friendly Air Compressors

Sustainability and going green are key concerns across many different industries today. Many companies are looking for more ways to green their processes and become more eco-friendly. There are many ways to go green today, and numerous benefits to the environment, human health and a company’s bottom line. Using more environmentally friendly air compressors is […]

Read MoreHow Pneumatic Tattoo Machines Work

Artists understand that their tools influence their work. A tattoo artist with a low-quality tattoo machine will likely feel a sense of limitation. Each of your clients wants a different type of tattoo, and the possibilities are endless. Are you ready to tackle any client request that comes your way? Having an optimal tattoo machine is […]

Read MoreHigh Pressure Screw Air Compressor

High pressure screw air compressors serve a wide range of purposes in industrial, manufacturing and other applications. Quincy Compressor has been manufacturing both low and high pressure machines since 1920. On this page, you’ll find a basic overview of high pressure compressor technology, as well as some advice on what to look for when shopping […]

Read MorePortable Air Compressor Parts

Portable air compressors are a popular choice for both home and commercial use. For a typical do-it-yourselfer or any application in which flexibility is essential, a portable compressor allows you to do more with less. Quincy Compressor is a leading manufacturer of portable compressors for a wide range of industries and applications. To help you […]

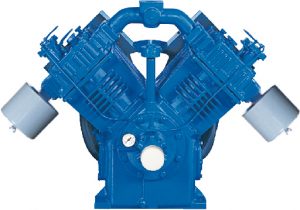

Read MoreWhat Is an Air Compressor Pump?

In many ways, a reliable pump represents the heart of an air compressor. The pump is a critical component that’s essential to helping the compressor do its job. When a pump fails, it has a significant impact on the unit’s performance. The good news is that you can save on the cost of a new […]

Read More