Chapter 5: Compressed Air Systems for the Automotive Industry

The creation of the automobile has a somewhat elusive and mysterious history, with some of the earliest designs traced back as far as Leonardo da Vinci. Steam and even electric-powered vehicles were invented in the late 18th and 19th centuries. Primitive forms of automobiles have their engineering roots in the industrial boom of the years leading up to the mid-1800s, but the first true automobile did not arrive until 1885, according to Library of Congress.

The creation of the automobile was the first step in an ever-expanding history, which has led to the birth of numerous successful automotive manufacturers across the world, many unique designs and a widening consumer availability. Driving a car or a truck today is only a part of daily life for many people around the world, but the engineering and manufacturing feats that have led to modern innovations are quite remarkable when looking at the humble, mechanical foundations of the industry.

Automobiles have provided indispensable usefulness to the average consumer for travel, automotive sports and the transportation of goods. In addition, prototypes have been created in the wake of the industrial boom, which advanced engineering sciences and vehicular safety.

Automotive practices advanced from Henry Ford’s human-powered assembly lines. Computer technologies and automated assembly systems changed the face of the entire industry. Manufacturers today can supply consumers with safer, more fuel-efficient and reliable vehicles than ever before. The automotive industry improved through the use of modern compressed air systems, as well.

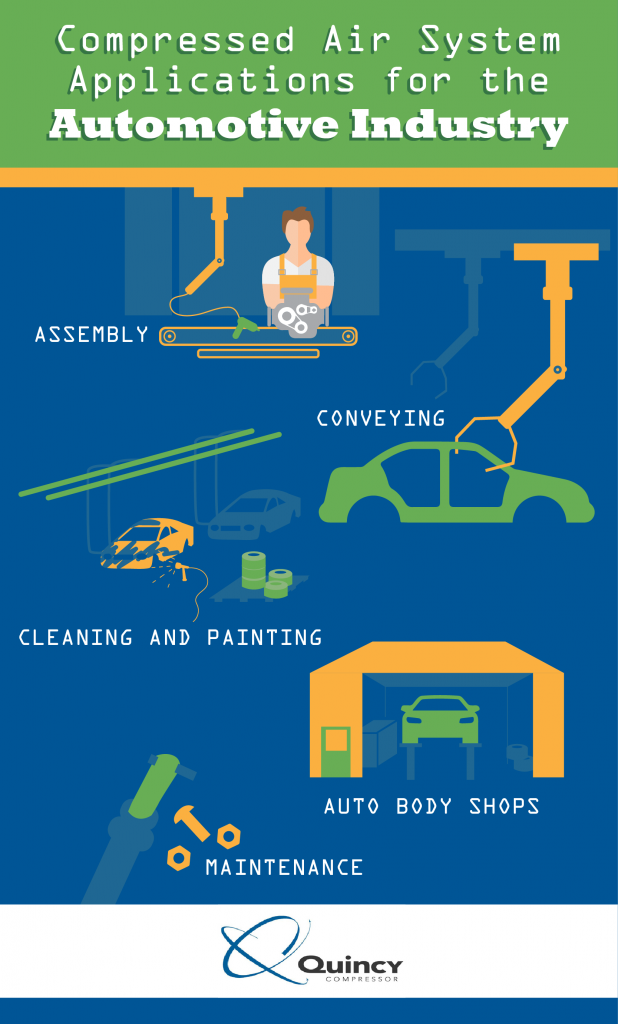

Compressed air is a vital utility in almost every aspect of the automotive industry, ranging from vehicle assembly to engine construction and painting and cleaning. A more obvious use includes the auto tire business. From the corporate assembly line to the local auto body shop, air compressors are undeniable assets to the industry.

In the past 100 years alone, computers and automated technologies dramatically altered the automotive industry, but skilled technicians are still required to assemble the components that make your favorite automobile run as it should. Through the assembly stages, automotive air compressors are the tools that keep the wheels turning on the production line.

Traditionally, automobiles were almost entirely composed of steel and metal parts, but the advancements in technology have allowed for the use of durable, petroleum-based products like plastic, which can help significantly reduce the weight of modern vehicles. Pneumatic tools help create automotive parts, both big and small.

In the early stages of assembly, the shell is secured on a conveyer system and sent onward down the production line. From there, all of the major components will be installed, including the gas tank, suspension, axles, brakes and even the steering system.

Modern robotics often put the engine and transmission into place. Today, the people assembling the vehicle’s components can use machines to do much of the heavy lifting once handled by a group of skilled laborers. Assemblers use compressed air for many tasks when building the components, including air-powered wrenches that fasten component screws.

Using compressed air, robotic machinery can also lift, transport and position many of the components that once completed by hand. Compressed air systems help put quarter panels, door pillars, side panels and roof pieces into place.

Before painting begins, the vehicle is inspected to find any defects. Both the cleaning and painting processes utilize compressed air, as well as in the conveyer systems that move the newly assembled car or truck down the production line.

Many auto body shops and garages use compressed air systems. Clean, dry and contaminant-free compressed air is needed to achieve a perfect finish with paint. Air dryers can help produce a smooth mirror finish for airbrushed painting.

Quincy offers refrigerated dryers, which can chill temperatures to slightly above the freezing point to create moisture condensation. This can help minimize contaminants like dirt and oil within the stream of air. A small- to medium-sized air compressor can even make minor car repairs.

Removing nuts and bolts with an air ratchet, for example, makes the task easy enough for nearly anyone to perform, unlike the use of traditional wrenches. Grinding and cutting metal can also be achieved with small, air-powered saws.

Quincy recommends several products that can help improve the operations of everything from small do-it-yourself projects to the more demanding tasks in the auto body shop. Look at our highly efficient, top-performing rotary screw, reciprocating air compressors, dryers and air filtrations solutions:

- QGS and QGD rotary screw series compressors

- Refrigerated dryers

- Air filtration solutions

- QT, QP and QR series piston air compressors

If you are seeking additional information about how we can best serve your automotive business, please contact Quincy today or read more at the automotive section of our website. Quincy has delivered reliable compressed air solutions to the automotive business for generations, and our experienced team has the expertise to help you with nearly any task.

Table of Contents

- The Evolution of Compressed Air — An Essential Element to Industry

- Chapter 8 Conclusion: Compressed Air Systems Utilized in Manufacturing

- Chapter 2: The Modern Industrial Compressed Air System

- Chapter 4: Natural Gas Industry and Compressed Air

- Chapter 3: Woodworking and Compressed Air

- Chapter 5: Compressed Air Systems for the Automotive Industry

- Chapter 6: Compressed Air Systems in Agricultural Use

- Chapter 7: Compressed Air in the Medical and Pharmaceutical Industries